Optical sensory element and its manufacturing method

A light sensor, conductive type technology, applied in the field of clip-on photodiode structure, can solve the problem of not covering shallow trench insulation structure, incompatibility, difficult to control shallow source/drain junction of clip-on photodiode, etc. problem, to achieve the effect of improving dark current characteristics and response improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure of the light sensor according to the embodiments of the present invention will be described below. Although the disclosed embodiments are NPN-type clip-on photodiode structures, these embodiments are also applicable to PNP-type clip-on photodiodes. structure.

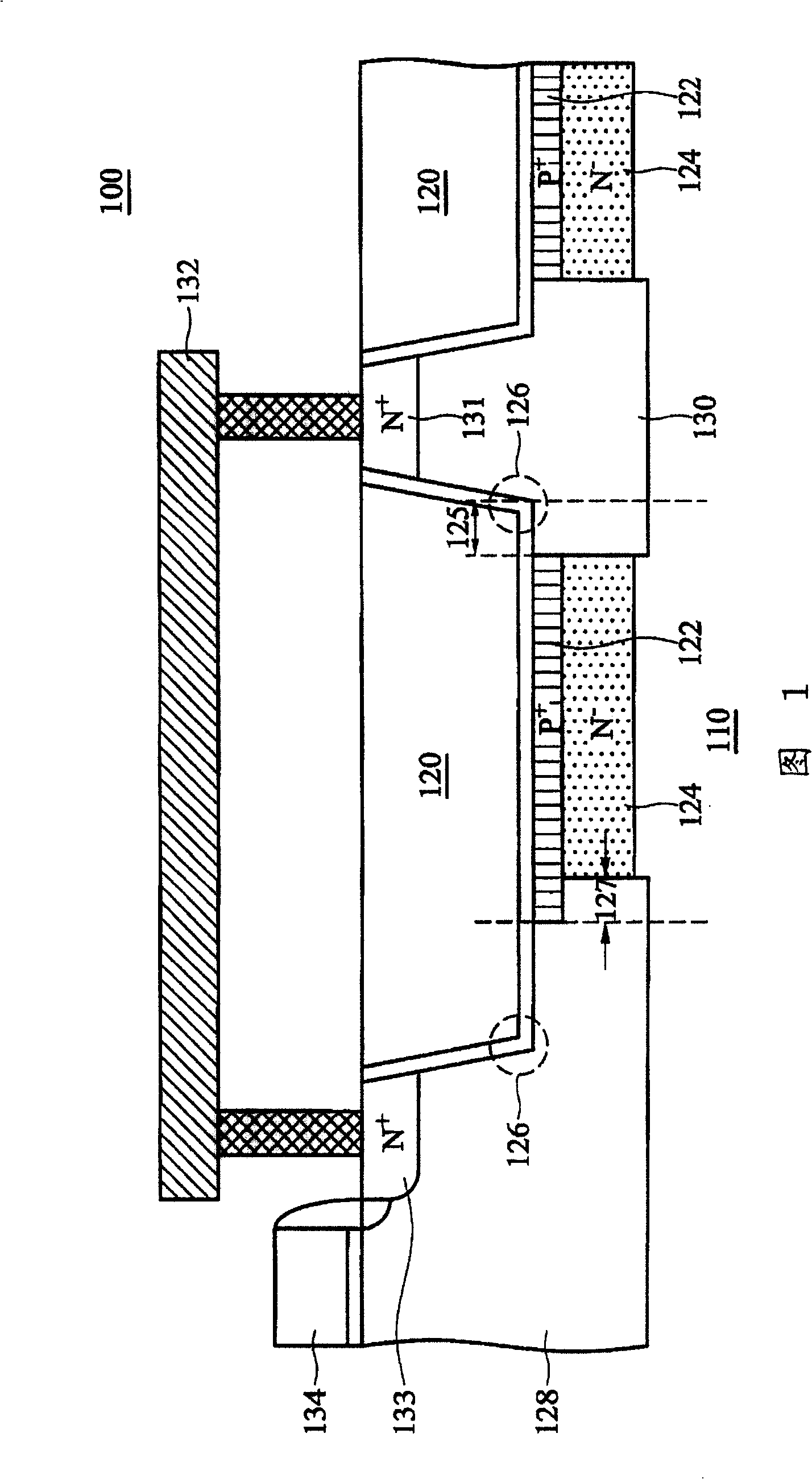

[0027] FIG. 1 illustrates a photosensor according to an embodiment of the present invention. The photosensor 100 includes a P-type substrate 110, at least one trench 120 formed in the substrate, and at least one P-type heavily doped region. 122 and at least one N-type lightly doped region 124, each P-type heavily doped region 122 is formed under a corresponding trench 120, each N-type lightly doped region is located in the corresponding P-type doped region 122 Between the substrate 110, the P-type heavily doped region 122 or the N-type lightly doped region 124 will not extend beyond the corner 126 of the trench. The distance 125 is between 0.1 and 0.3 microns; since there will still be some disloca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com