Heat insulating system outside external wall

A technology of external thermal insulation and thermal insulation boards for external walls, applied in the direction of thermal insulation, structural elements, building components, etc., can solve the problems of large-scale promotion and application of energy-saving buildings, failure to achieve flame retardant effect, failure of thermal insulation, etc., and achieve comprehensive performance of external walls Improve the effect of enhancing the bonding force and preventing the hollowing of the insulation wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

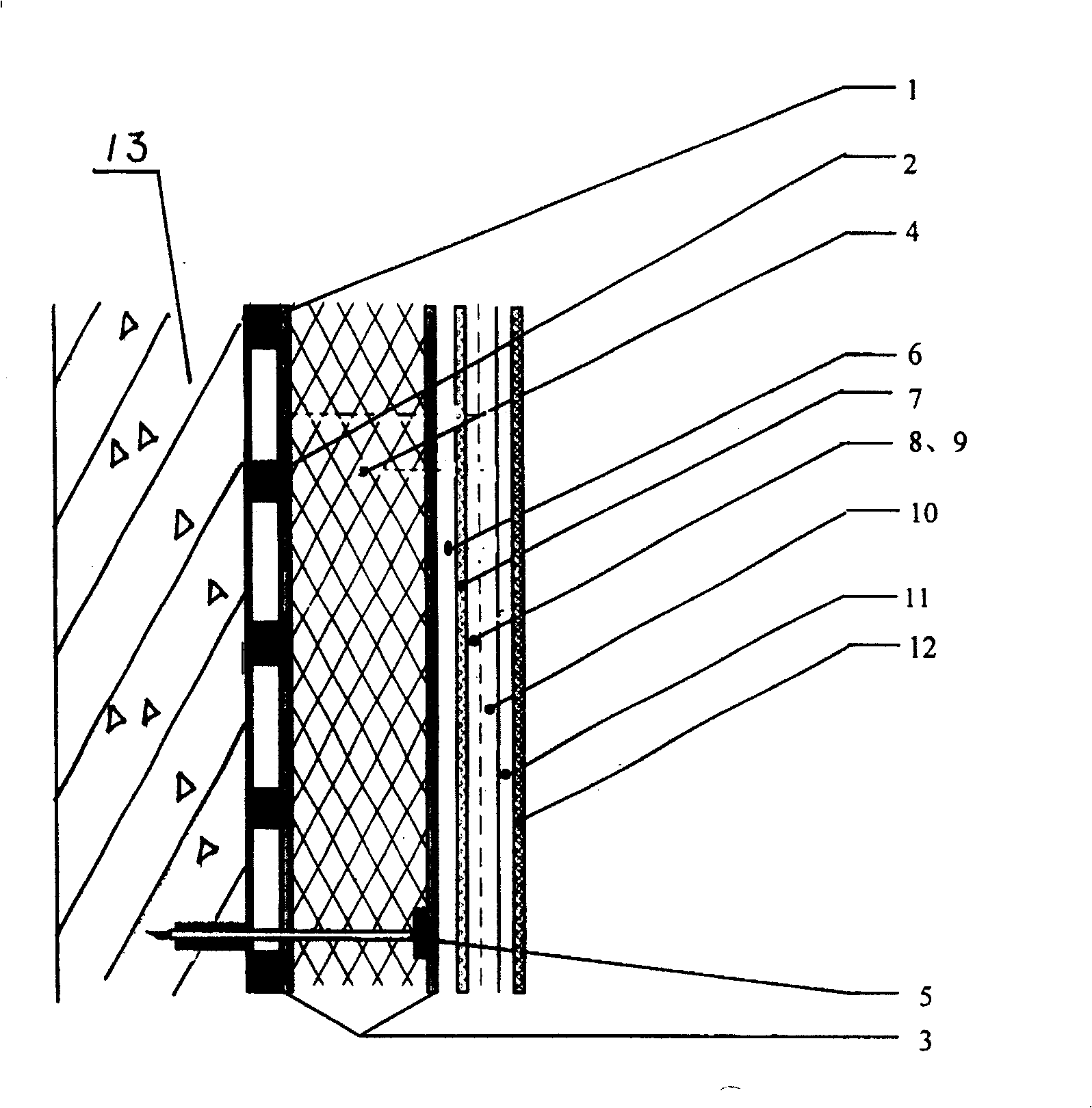

[0022] Such as figure 1 As shown, it is a schematic diagram of an external thermal insulation system for external walls. The external thermal insulation system for external walls consists of base-level anti-alkali enhancement treatment agent 1, silicon-modified polymer mortar binder 2, thermal insulation board 4, plastic anchors 5, Silicon-modified polymer elastic anti-crack putty 6, self-organized waterproof and anti-crack sealant 7, alkali-resistant mesh cloth 8, silicon-modified polymer plastering mortar 10, fire-retardant coating 11, silicon-modified acrylic coating 12, concrete foundation The wall base surface 13 is composed of a base base anti-alkali reinforcement treatment agent 1 outside the concrete foundation wall base surface 13, which is connected with the insulation board 4 through the silicon-modified polymer mortar adhesive 2 and the plastic anchor 5. Alkali-resistant grid cloth 8 is arranged outside the board 4, and silicon-modified polymer elastic anti-crack p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com