Self-insulating concrete house structural system

A technology of thermal insulation concrete and concrete walls, which is applied in the direction of building structure and construction, can solve the problems of unsatisfactory comfort and poor overall performance, and achieve the effects of convenient construction, cost reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

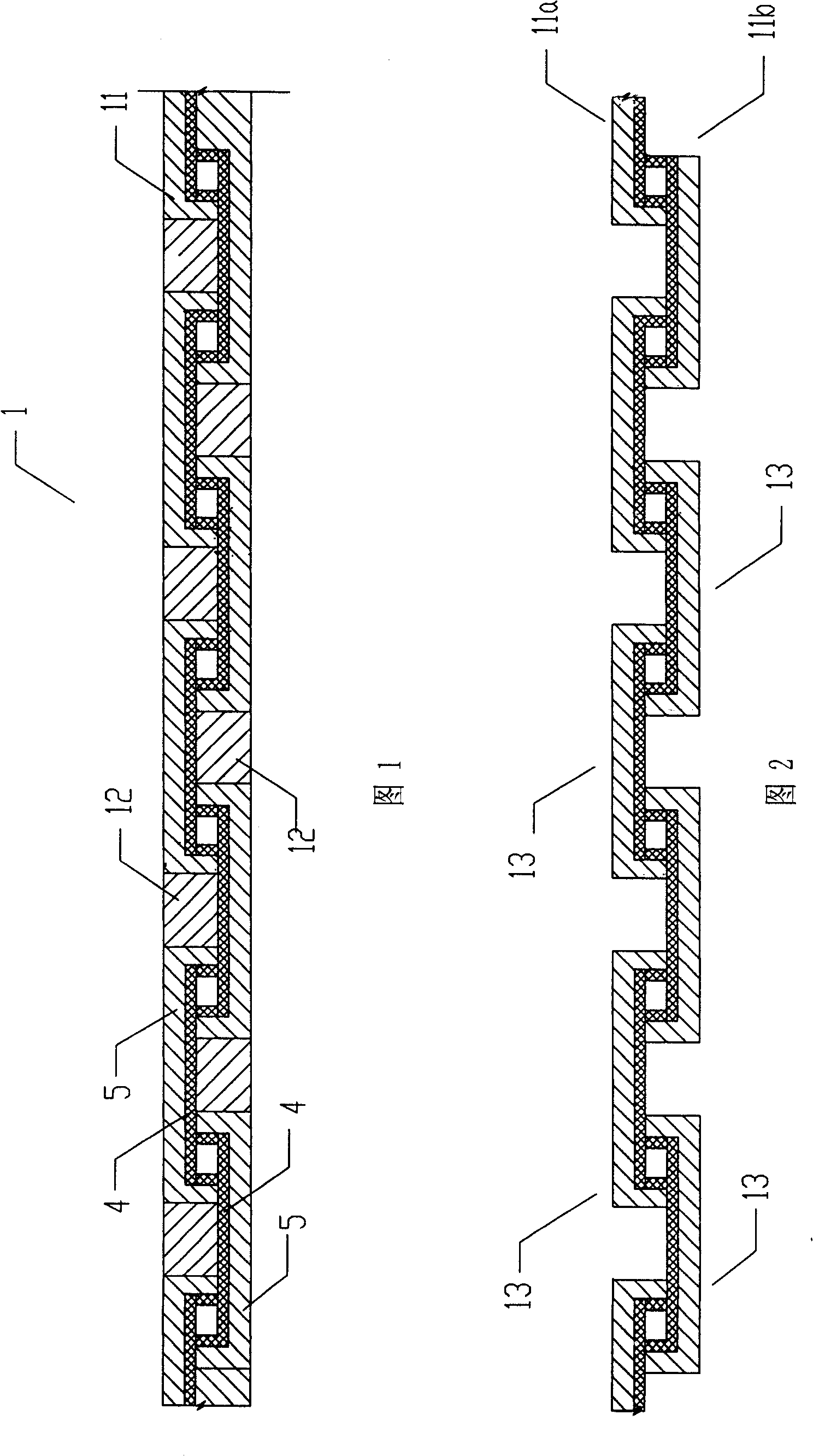

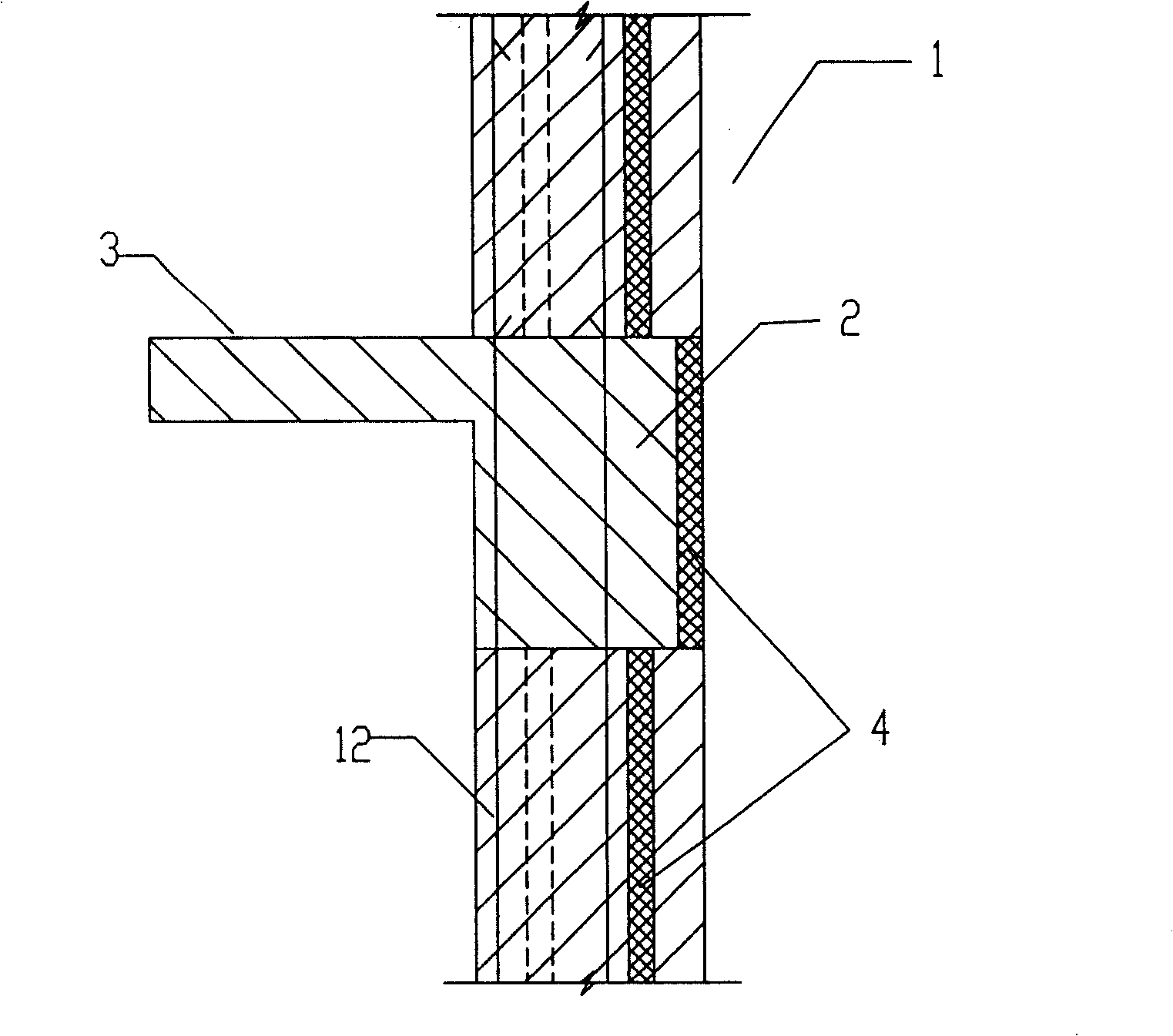

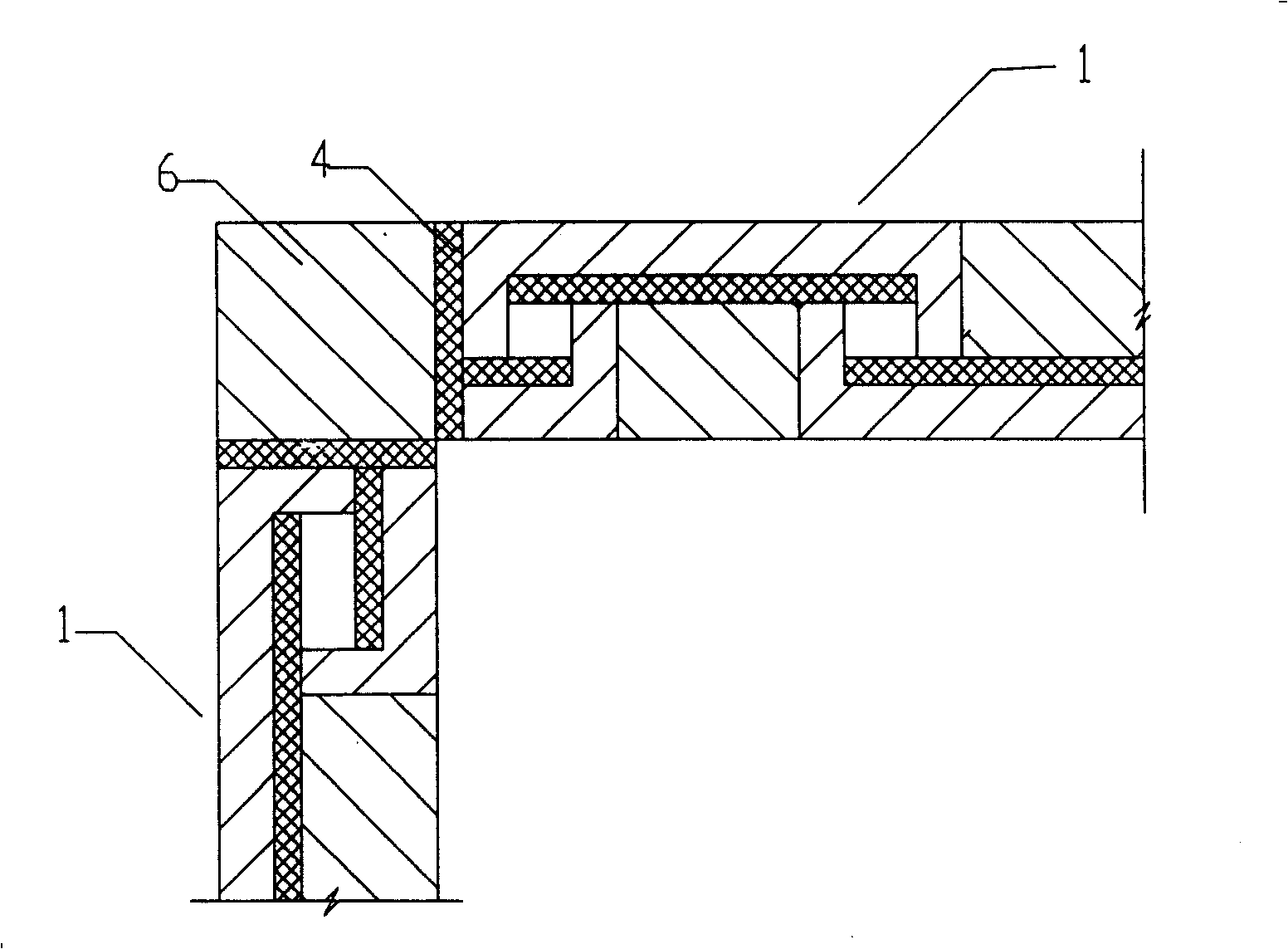

[0047] Referring to Figures 1 and 2, a structural system of self-insulating concrete houses includes a wall 1, connecting beams 2 and a floor 3, and two layers of prefabricated insulating concrete walls 11a and 11b are arranged in the outer wall 1, and the prefabricated insulating concrete walls 11a, 11b are concrete slabs 5 covered with thermal insulation material layer 4 on the inner surface, each layer of prefabricated thermal insulation concrete wall 11a, 11b is composed of several groove-shaped or L-shaped prefabricated thermal insulation concrete wall units 13, two adjacent There are cast-in-place concrete wall vertical ribs 12 between the prefabricated thermal insulation concrete wall units, and the cast-in-place concrete wall vertical ribs 12 connect two adjacent prefabricated thermal insulation concrete wall units 13 on the same floor; Concrete wall units 13 are staggered in such a way that the notches are opposite, the top of the groove rib of the wall unit 13 of one ...

Embodiment 2

[0054] see Figure 8 , a self-insulating concrete house structure system, including a wall 1, a connecting beam 2 and a floor 3, the wall 1 is composed of a prefabricated insulating concrete wall 11 and a cast-in-place concrete wall 12, and the prefabricated insulating concrete wall 11 is the inner surface The concrete slab 5 covered with the thermal insulation material layer 4, the prefabricated thermal insulation concrete wall 11 and the cast-in-place concrete wall 12 are superimposed and poured into one; The cast-in-place concrete wall body 12 is poured as a whole, and the outer end surface of the connecting beam 2 is covered with a thermal insulation material layer 4 .

[0055] see Figure 9 , 10, 11, internal screw holes 16 are embedded at intervals in the prefabricated thermal insulation concrete wall 11, and the screw 15 is inserted into the internal screw hole screw 16 and protrudes outside the thermal insulation material layer 4 of the prefabricated thermal insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com