L type bracket encapsulation for coaxial parts of semiconductor laser

A technology of lasers and semiconductors, applied in semiconductor lasers, structural details of semiconductor lasers, laser components, etc., can solve problems affecting device yield, large aberration coupling efficiency, cost increase, etc., and achieve fast, simple, reliable and efficient coupling packaging , reduce production costs, and simplify the coupling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

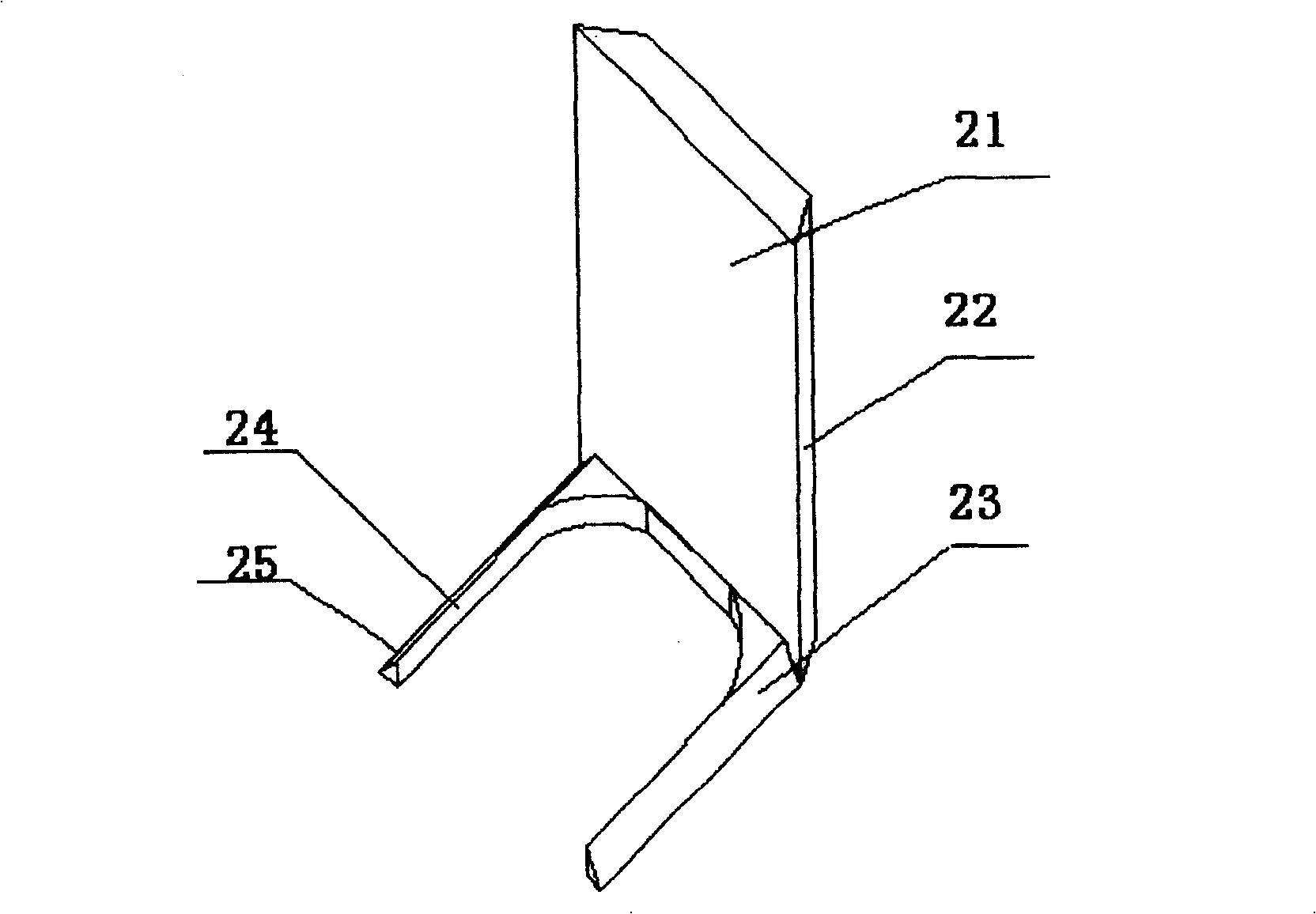

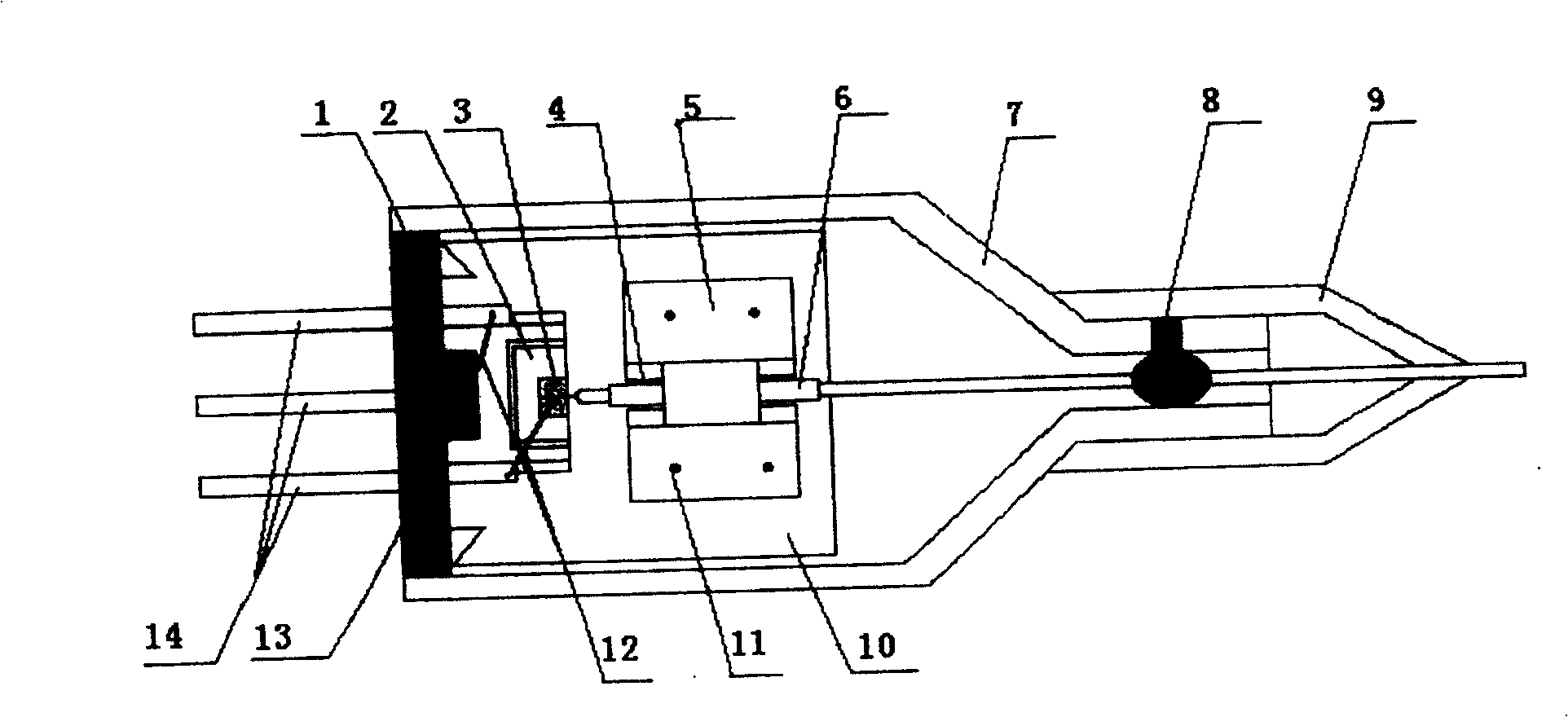

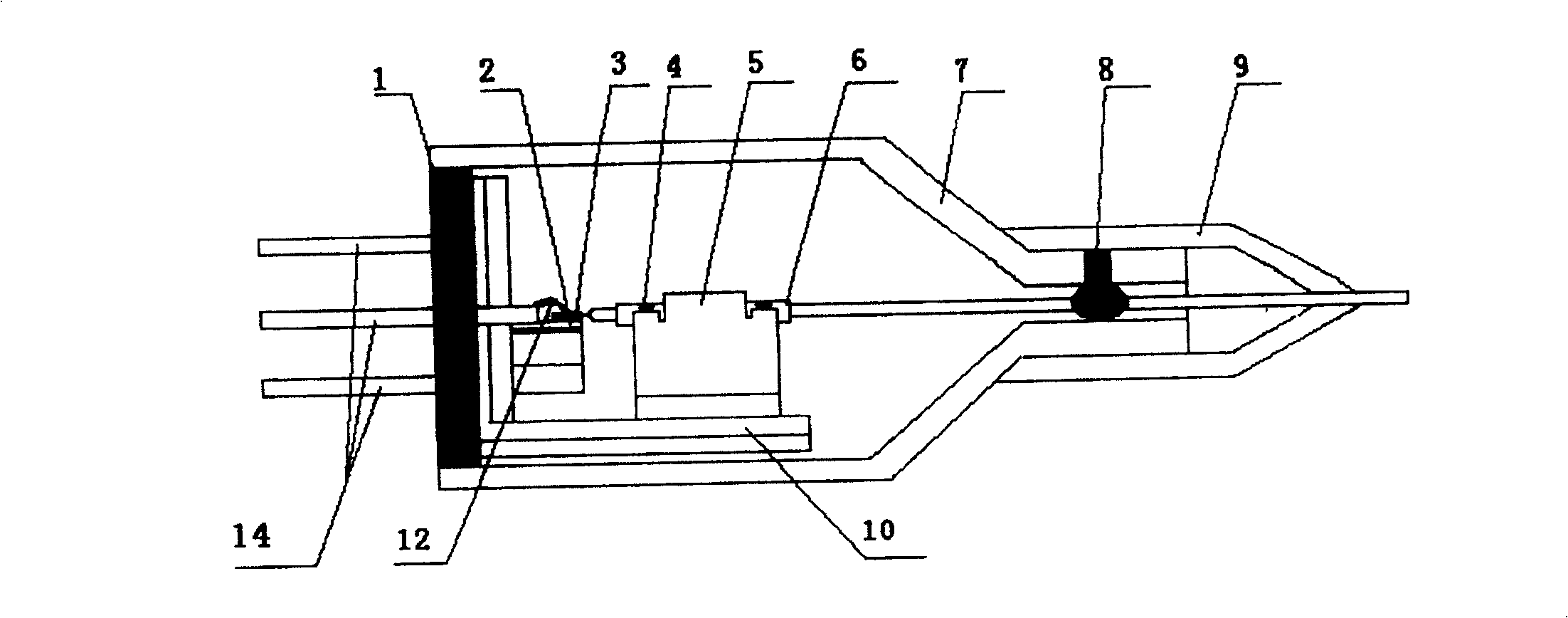

[0014] see figure 1 ,exist figure 1 In the embodiment of the present invention, the L bracket 10 requires a sufficiently large fixing area and a relatively strong supporting force, and at the same time, cannot be in contact with the pins 14 of the tube base and the tube shell 7 . Using wire cutting and finishing technology to make the bottom surface 25 of the L bracket 10 a U-shaped plane, that is, crossing the pin 14 and increasing the fixed contact area with the tube base 1 through the circular arc design, the two sides of the U shape are formed by the outer surface 23. A triangular cylinder formed by the inner side 24 and the bottom 25. This triangular structure is relatively stable. The outer side 23 is an inclined plane for laser welding, and the inner side 24 is perpendicular to the bottom. The fixed platform 21 is a trapezoidal prism with a large upper surface and a small lower surface, and the two sides 22 are processed into inclined surfaces, so that the inclined sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com