Method for producing dimethylbenzene and benzene through dismutation of toluene and transference of alkyl

A technology of alkylation transfer and toluene disproportionation, which is applied in the fields of chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of poor adaptability of radial reactors, catalyst poisoning, short circuit of reaction gas, etc., and improve the effective utilization rate , conversion rate improvement, life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

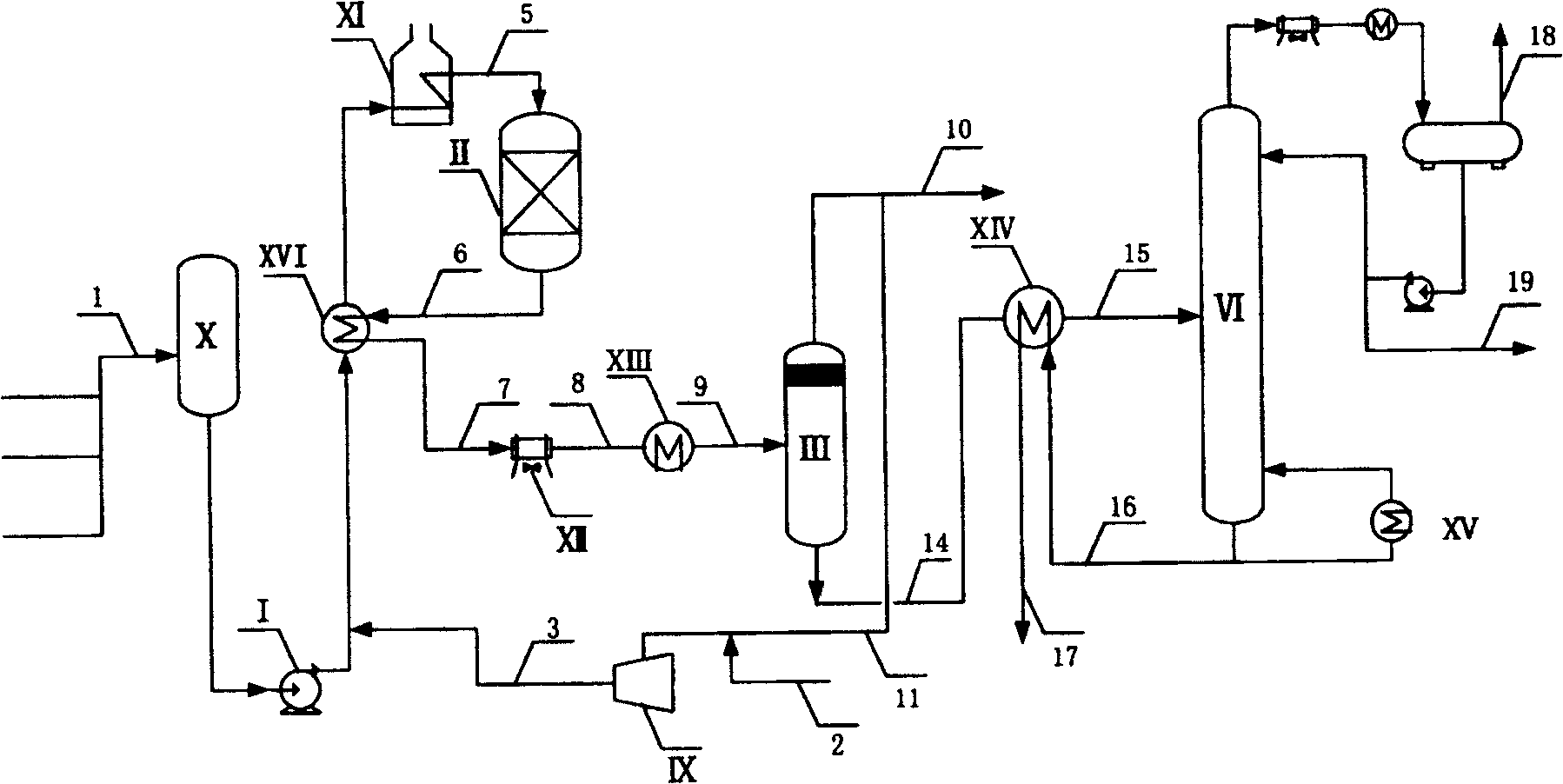

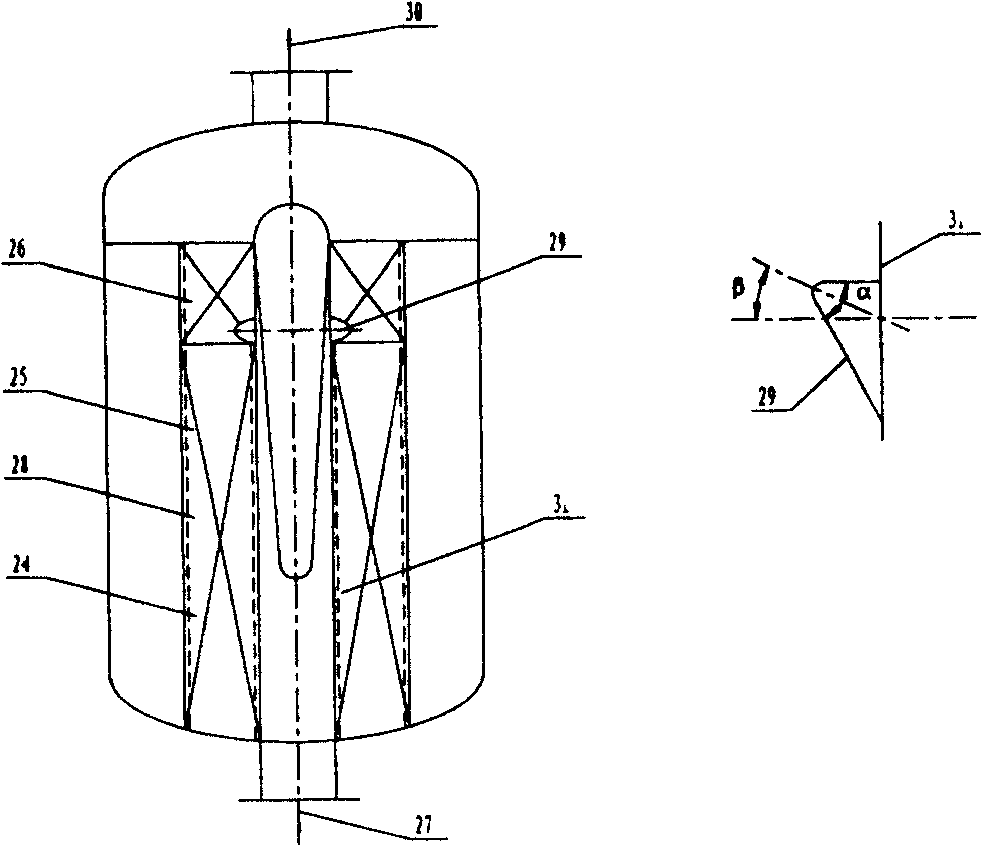

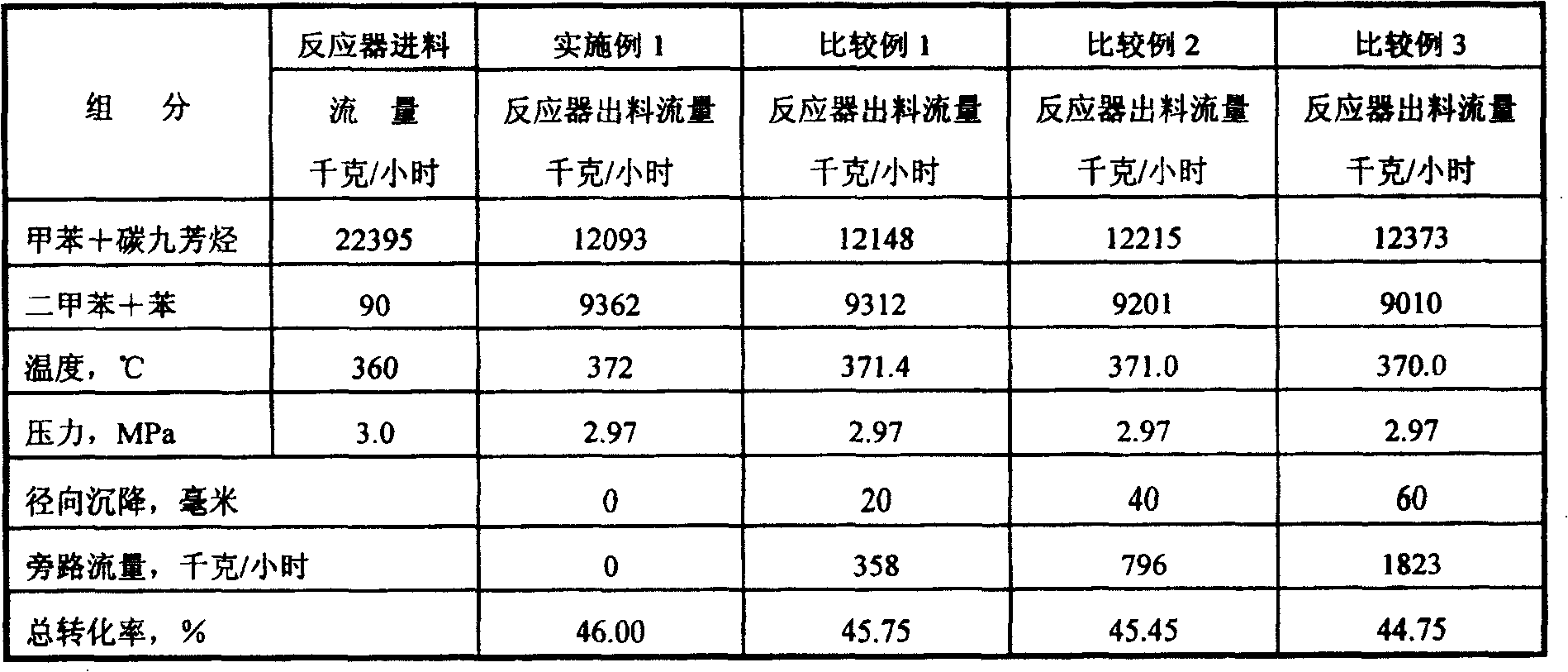

[0023] The catalytic reaction of toluene and carbon nine and above aromatics in hydrogen atmosphere is carried out with a set of equipment, and its production block diagram is shown as figure 1 . The reactor uses figure 2 In the reactor, the catalyst used is bismuth-containing mordenite. The diameter of the distribution cylinder in the reactor is 1200 mm, the radial thickness of the bed is 800 mm, and the total static height is 10000 mm. The shape of the flange 29 at the intersection of the axial section 26 of the reactor and the radial section 25 of the inner distribution cylinder 31 is triangular, and the angle α of the triangle that penetrates into the catalyst bed is 40 degrees, and the symmetry line of the apex angle is perpendicular to the inner distribution cylinder (that is, the β angle is 0), and the vertical height between the top of the flange and the inner distribution cylinder is 100 mm. The temperature of the reaction materials entering the reactor was 360° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com