Vacuum filter

A filtration device and vacuum technology, which is applied in filtration and separation, fixed filter element filters, mobile filter element filters, etc., can solve the problems of reducing the interval between vacuum hoses, increasing the number of connecting parts, and difficult to ensure storage space, etc. The effect of suppressing tilt, achieving stability, and suppressing obstacles to movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

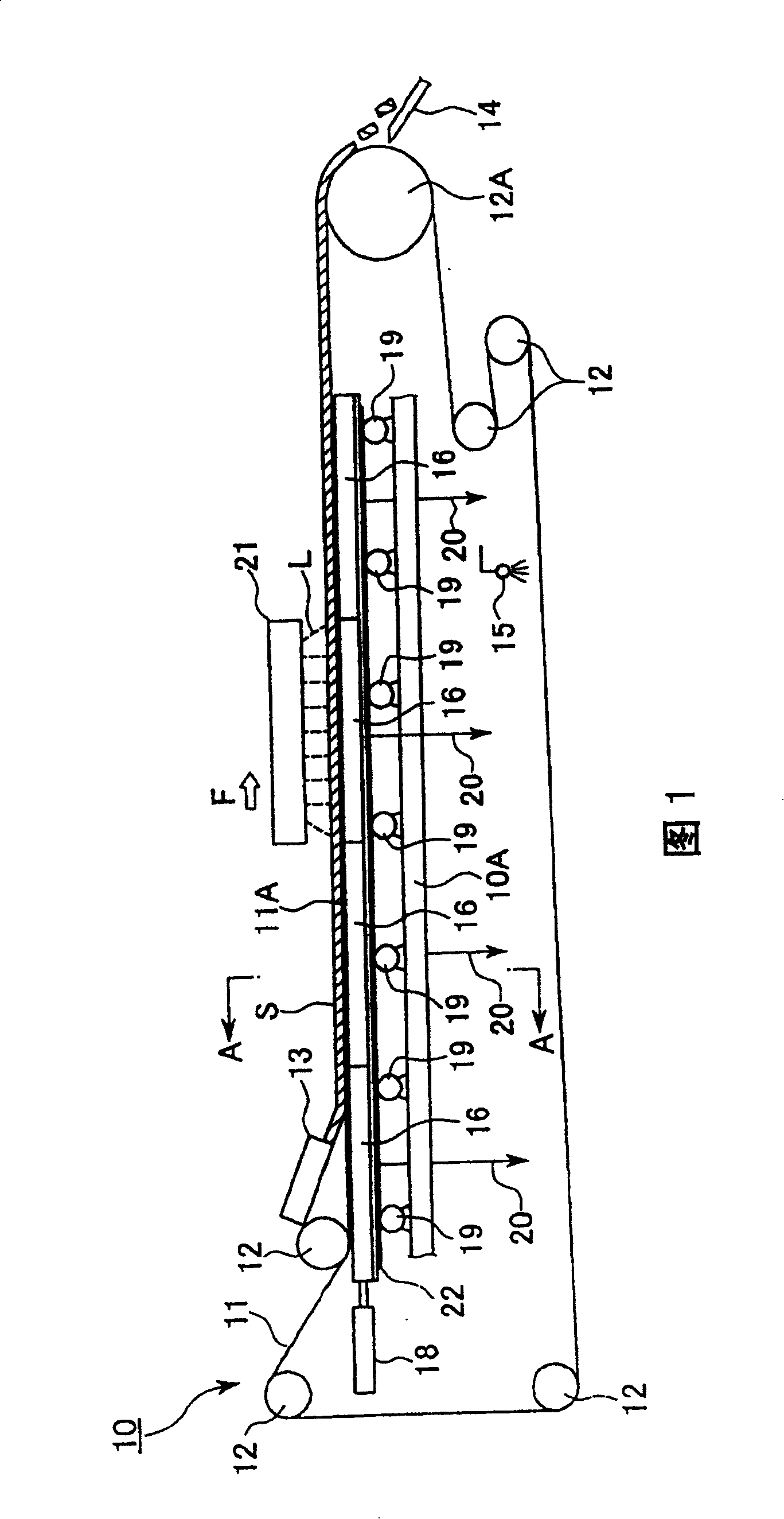

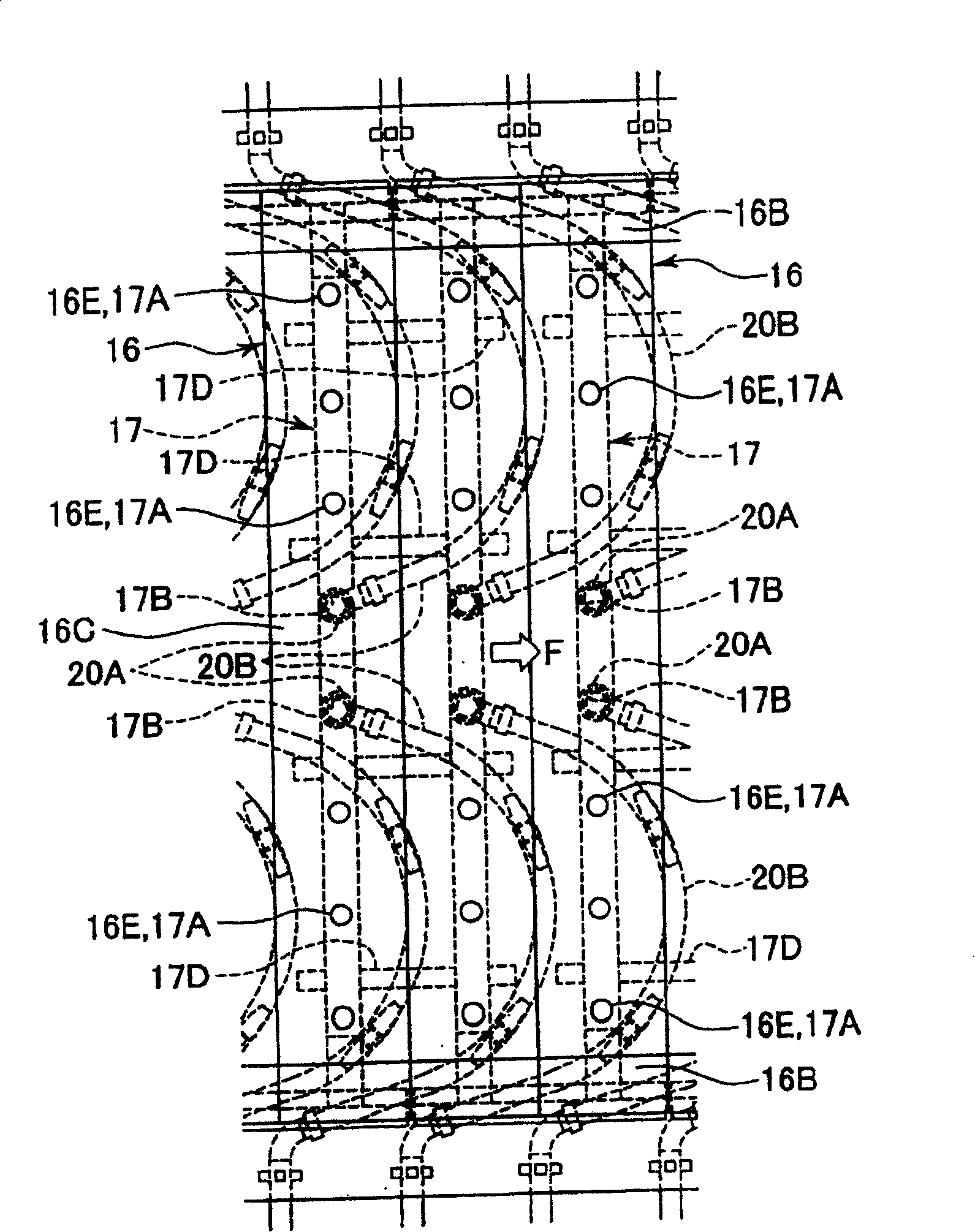

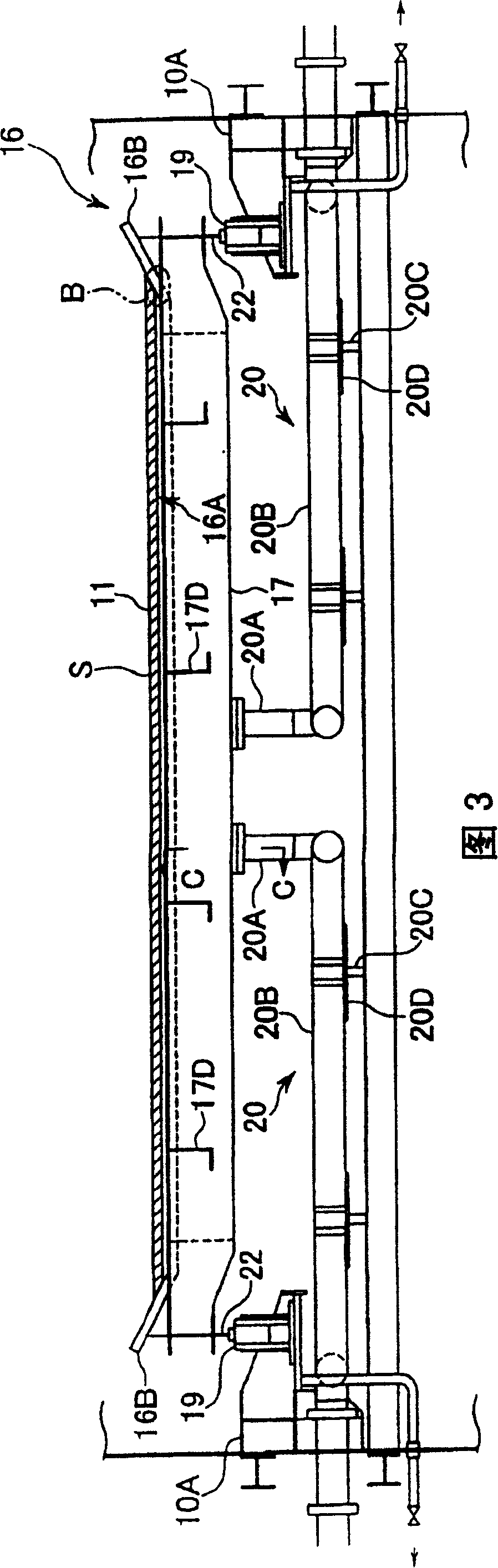

[0022] Figure 1~ Figure 5 It is a figure which shows one embodiment of this invention. In the vacuum filter device of this embodiment, in the device main body 10, the endless belt-shaped filter cloth 11 is wound on a plurality of rollers 12 in sequence, and the upper part of the filter cloth 11 is arranged so as to extend horizontally. It becomes the filter part 11A. And, on one end side (the right side in FIG. 1 ) of this filter part 11A, the roller 12A on which the filter cloth 11A is wound is connected to a driving device not shown in the figure, and the roller 12A is driven by the driving device to turn to the drawing. Rotating clockwise, the filter cloth 11 is also continuously driven around the rollers 12..., and with this, the filter part 11A of the filter cloth 11 moves continuously in the moving direction shown by the arrow F in the figure.

[0023] On the other end side (left side in FIG. 1 ) of the filter portion 11A of the filter cloth 11 , that is, above the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com