Process of preparing refined salt with sodium-containing bittern

A technology for refining salt and brine, applied in the direction of alkali metal chloride and the like, can solve the problems of low quality of refined salt, many impurities in sun-dried salt and high production cost, and achieve the effects of high product purity, simple process and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

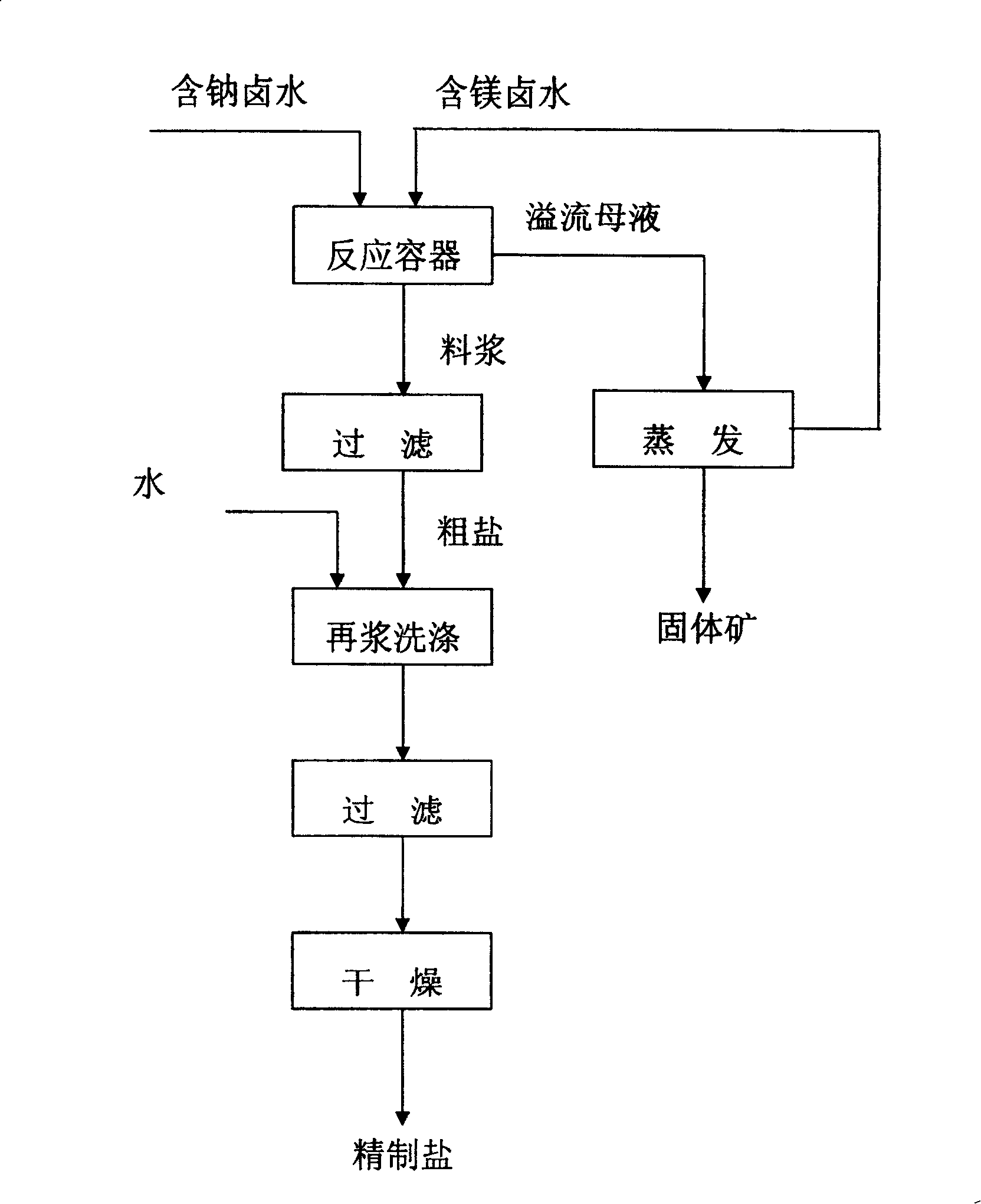

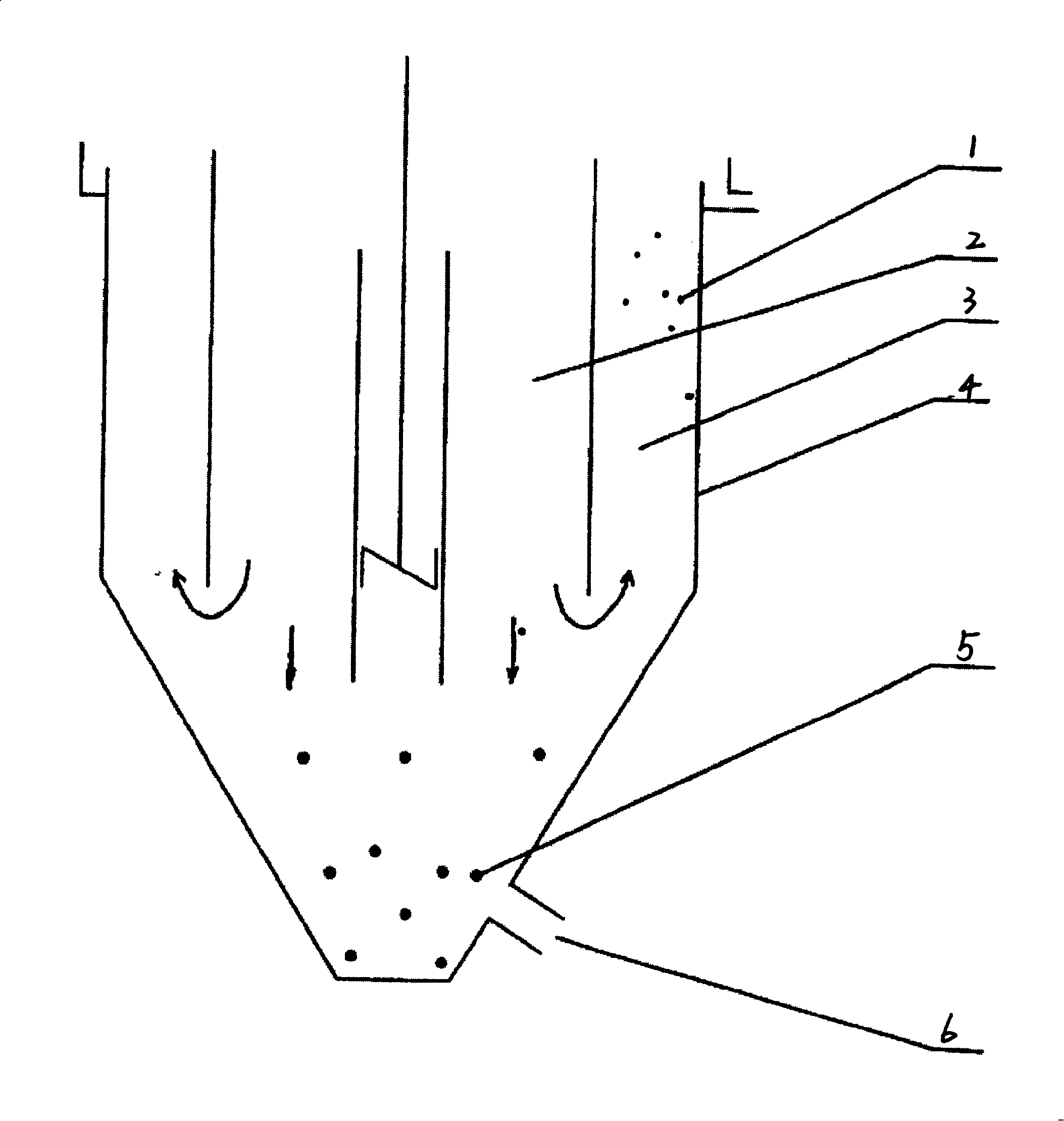

[0014] Example 1. refer to figure 1 , figure 2 . A kind of method that utilizes sodium-containing brine to produce refined salt, NaCl content is 8% sodium-containing brine and Mg 2+ The magnesium-containing brine with a content of 8% is added to the reaction zone 2 of the reaction vessel 4 at a constant speed in a weight ratio of 1:1, and the full-mixed flow is continuously stirred to carry out the halogen-mixed crystallization reaction, so that the crystals containing part of the smaller particle size 1 And the mother liquor of other impurity, overflow reaction vessel 4 upwards from the periphery 3 of reaction zone 2, the slurry that will contain larger particle size sodium chloride crystal 5 below reaction vessel 4 reaction zone 2 is from the lower outlet 6 of reaction vessel 4 Release and remove the mother liquor to obtain solid-phase sodium chloride crystals, that is, crude salt. After repulping, washing, filtering and drying, refined salt is obtained.

Embodiment 2

[0015] Example 2. refer to figure 1 , figure 2 . A kind of method that utilizes sodium-containing brine to produce refined salt, NaCl content is 24% sodium-containing brine and Mg 2+ The magnesium-containing brine with a content of 9.2% is added to the reaction zone 2 of the reaction vessel 4 at a constant speed in a ratio of 1:4 by weight, and the full-mixed flow and continuous stirring are carried out to carry out the halogen-mixed crystallization reaction, so that the crystals containing part of the smaller particle size 1 And the mother liquor of other impurity, overflow reaction vessel 4 upwards from the periphery 3 of reaction zone 2, the slurry that will contain larger particle size sodium chloride crystal 5 below reaction vessel 4 reaction zone 2 is from the lower outlet 6 of reaction vessel 4 Release and remove the mother liquor to obtain solid-phase sodium chloride crystals, that is, crude salt. After repulping, washing, filtering and drying, refined salt is obta...

Embodiment 3

[0016] Example 3. refer to figure 1 , figure 2 . A kind of method that utilizes sodium-containing brine to produce refined salt, the NaCl content is 15% sodium-containing brine and Mg 2+ The magnesium-containing brine with a content of 6.2% is added to the reaction zone 2 of the reaction vessel 4 at a constant speed in a ratio of 1:2 by weight, and the full-mixed flow is continuously stirred, and the halogen-mixed crystallization reaction is carried out for 90 minutes, so that the containing part has a smaller particle size The mother liquor of crystal 1 and other impurity overflows reaction vessel 4 upwards from the periphery 3 of reaction zone 2, and the slurry containing larger particle diameter sodium chloride crystal 5 below reaction vessel 4 reaction zone 2 is exported from the lower part of reaction vessel 6 release and remove the mother liquor to obtain the solid phase sodium chloride crystals, which is the crude salt. After repulping, washing, filtering and drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com