DC brushless oscillating motor

A vibrating motor and DC brushless technology, which is applied in the direction of electric components, mechanical energy control, electrical components, etc., can solve the problems of large eccentricity between the ring magnet and the rotation center, the inability to realize the miniaturization design of the motor, and increase the input power. Small number, reduced winding complexity, and the effect of reducing the number of motor parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

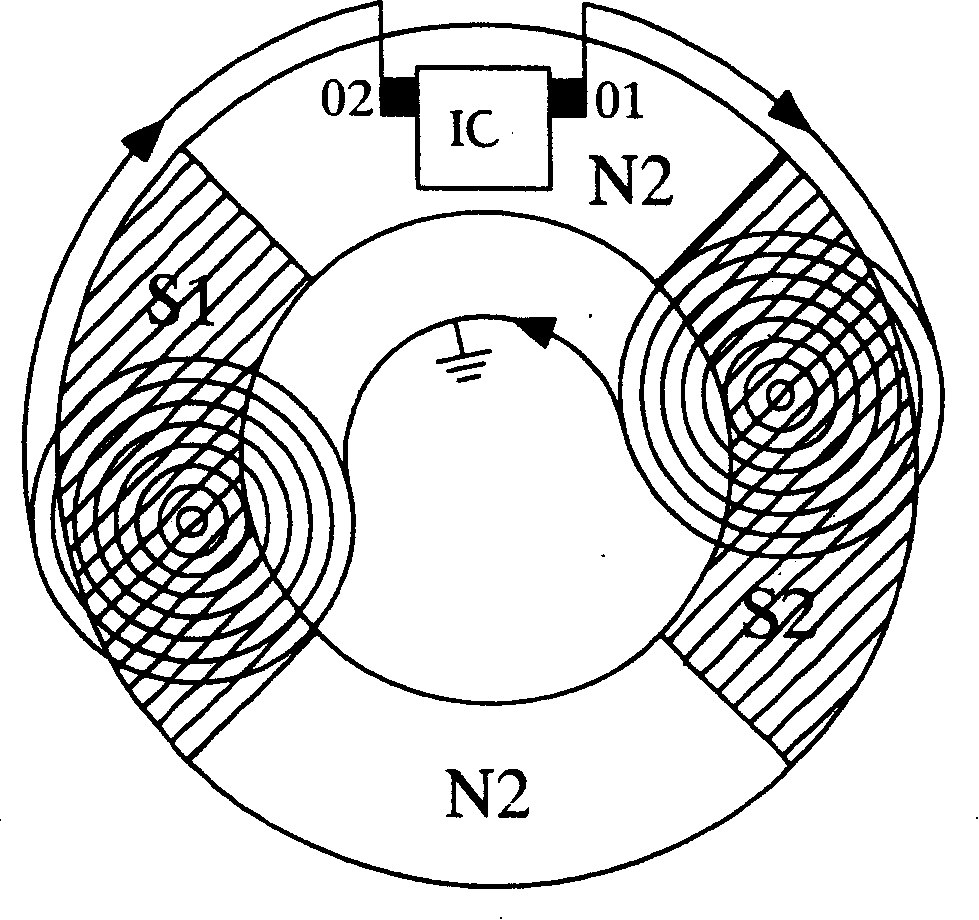

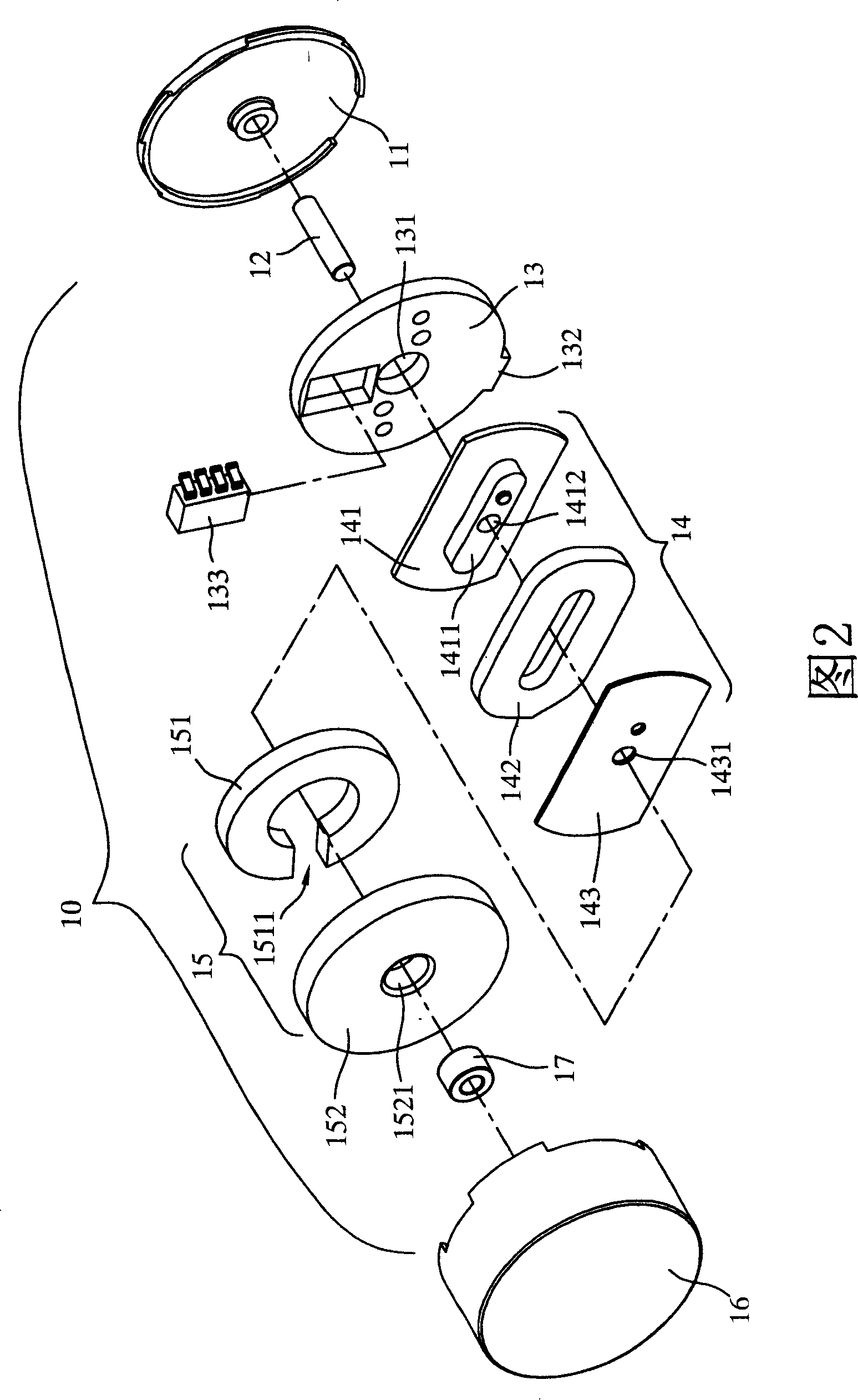

[0031] Please refer to Figure 2~ Figure 4 As shown, according to the brushless DC vibration motor 10 disclosed in the present invention, it includes a chassis 11, a shaft 12, a circuit board 13, a winding group 14, a rotating device 15 and a casing 16; wherein the chassis 11 It is in the shape of a disc, and the shell 16 is in the shape of a hollow cylinder. The shell 16 can be combined with the chassis 11 to form the appearance of a flat cylindrical brushless DC vibration motor 10, and can accommodate the axis 12 and the circuit board. 13. The winding group 14 and the rotating device 15 are contained therein.

[0032] The axis 12 is set at the center of the chassis 11 and defines the rotation center of the brushless DC vibration motor 10. The circuit board 13 is circular and has a perforation 131 in the center to be sleeved on the axis 12 and set on the chassis 11. Above, a power input port 132 is provided on the circuit board 13 to be electrically connected with an externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com