Tea moisture drying nano forming method

A technology for drying and tea leaves, applied in the direction of tea treatment before extraction, can solve the problems of excessive coke, destroy the chlorophyll of tea leaves, affect the quality of tea leaves, etc., and achieve the effect of avoiding over and under, average drying effect and good drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

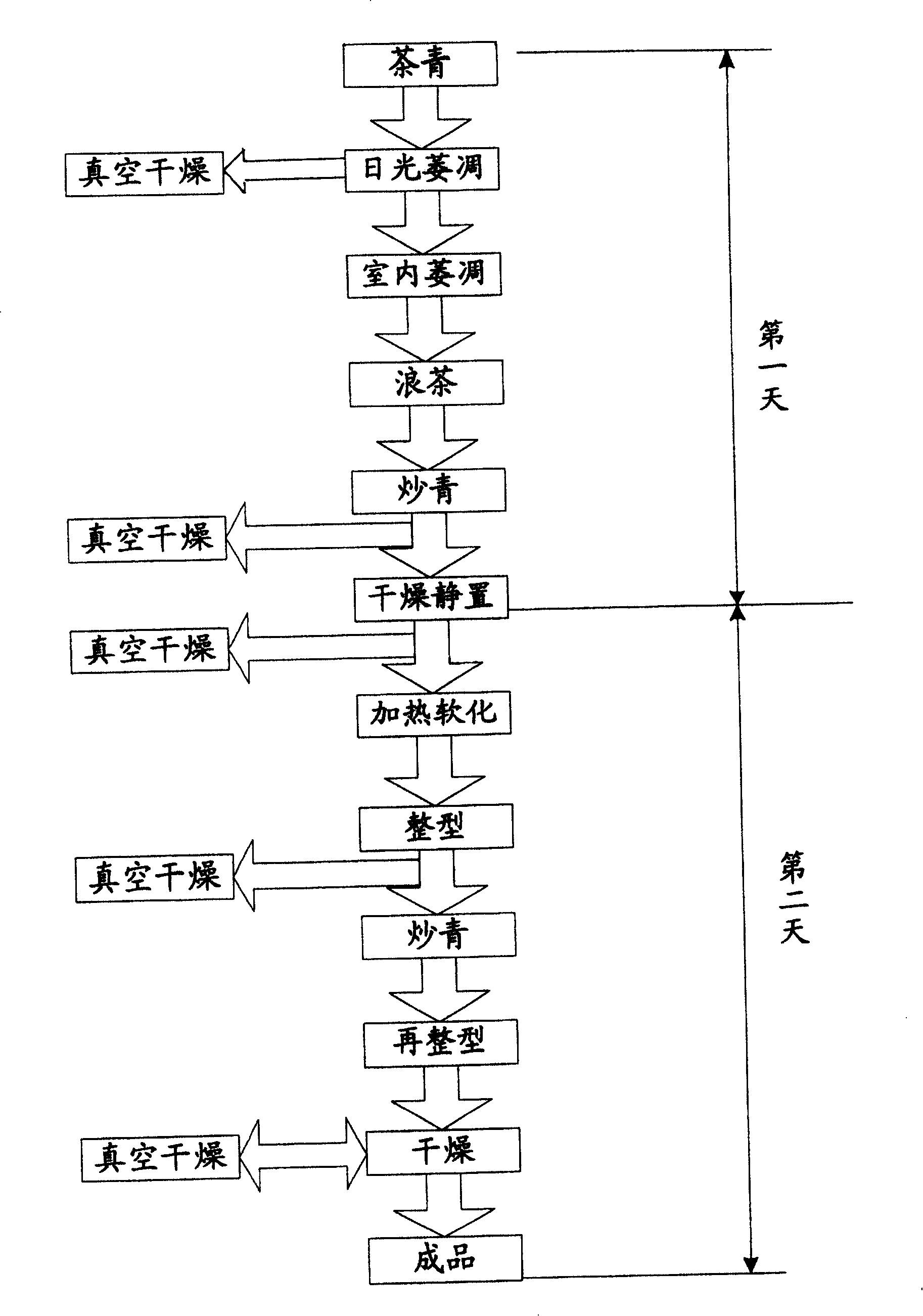

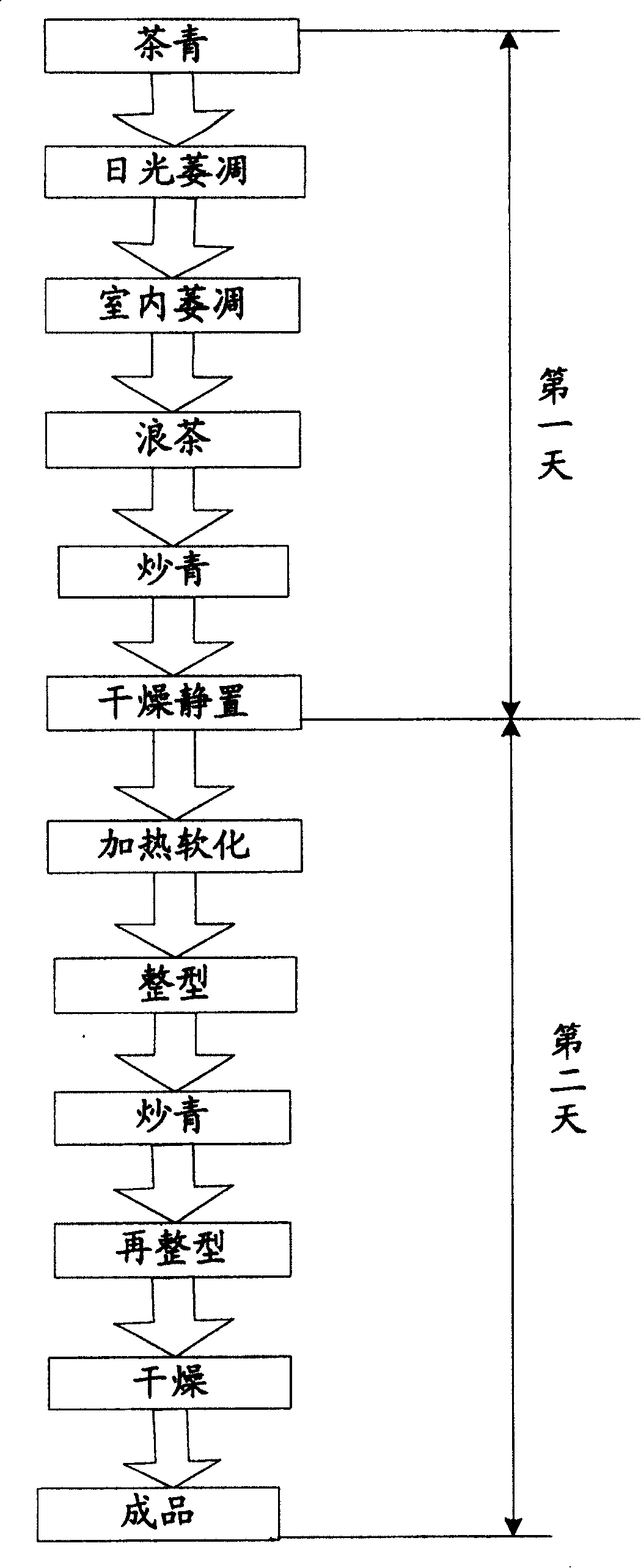

[0024] see figure 1 As shown, it is a flow chart of the present invention related to a tea water drying and nano-forming method. The main production process of the tea of the present invention is the same as the traditional tea making method, and it mainly uses a vacuum drying method to assist or replace the traditional method. The hot air drying method used in the method:

[0025] It mainly starts from harvesting the green tea, and withering in the sun to soften the tea green, remove the green smell, and remove part of the water. If the weather is bad, it can use vacuum drying instead of withering in the sun, which can also remove green tea. The effect of removing water from the leaves, and then move the tea leaves indoors for indoor withering, and at the same time, through the contact between the green tea and air to generate oxidation and form fermentation, use air conditioners or dehumidifiers to remove part of the water, and then carry out the wave tea process , to st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com