Apparatus used for solid absorption stirrer thermal analyzer

An adsorption stirring rod and thermal desorption technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of complicated devices, high cost, and difficulty in popularization and use, and achieves the effects of low power consumption, convenient operation and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

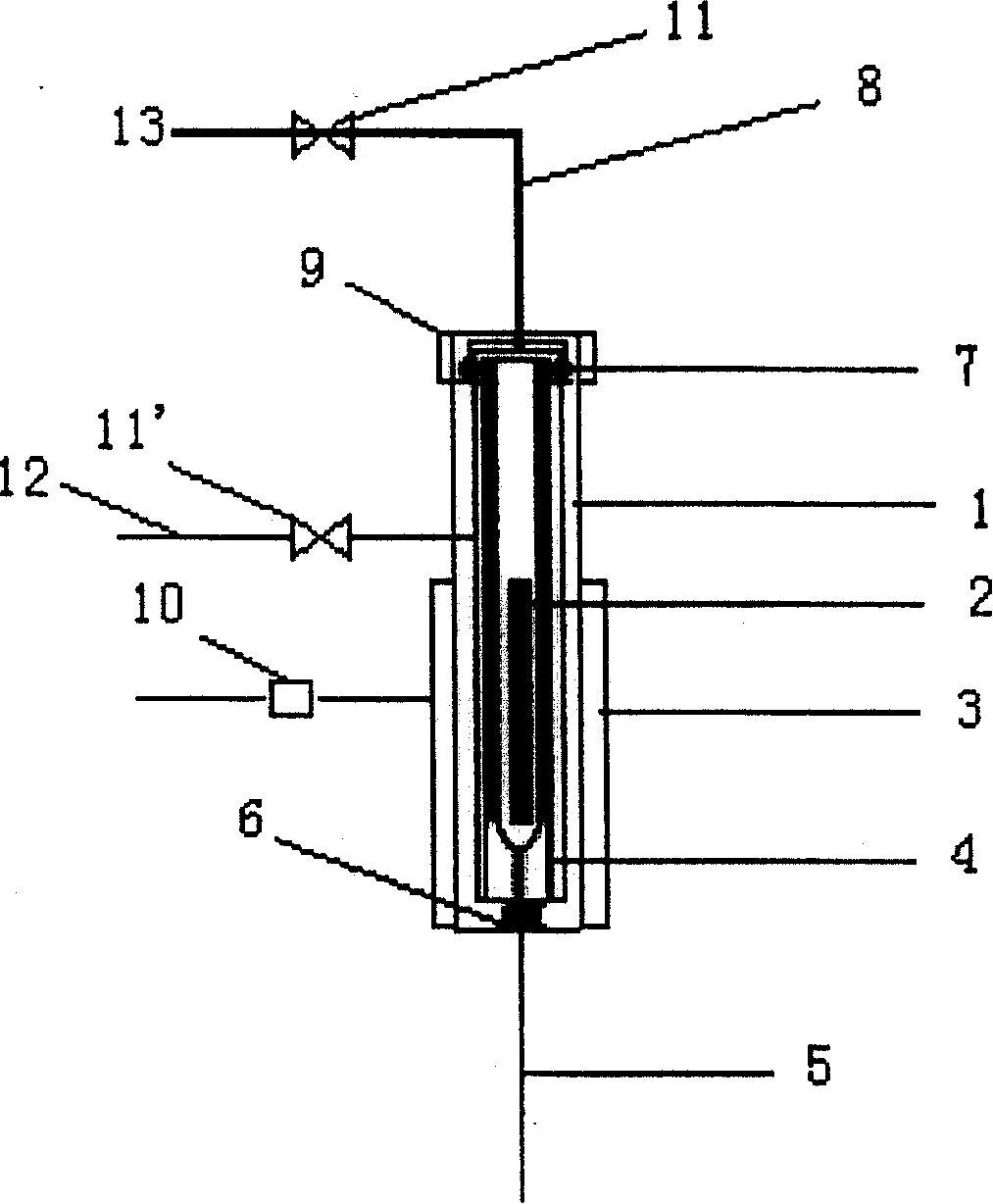

[0031] Such as figure 1 As shown, the sample transfer tube 5 is connected to the analysis tube 1 through the sealed ferrule 6, the single-closed liner tube 4 is put into the resolver 1, and the analysis purge gas path 13 and the auxiliary gas path 12 are connected, and then the resolver Placed on the top of the gas chromatographic inlet, the sample transfer tube 5 passes through the injection pad of the inlet and inserts 20 cm into the retention spacer pre-column. The flows of the analytical purge gas path 13 and the auxiliary gas path 12 are regulated through the steady flow valves 11 and 11'. Put the extraction and adsorption rod 2 into the thermal analysis liner 4, set the graphite O-ring 7, press the upper cover 9 of the resolver connected with the purge gas pipeline 13, and the resolver will be resolved under the action of the fastening nut. Tube 1 is sealed. The start temperature controller 10 heats the resolver through the heating body 3 . The substances adsorbed on ...

Embodiment 2

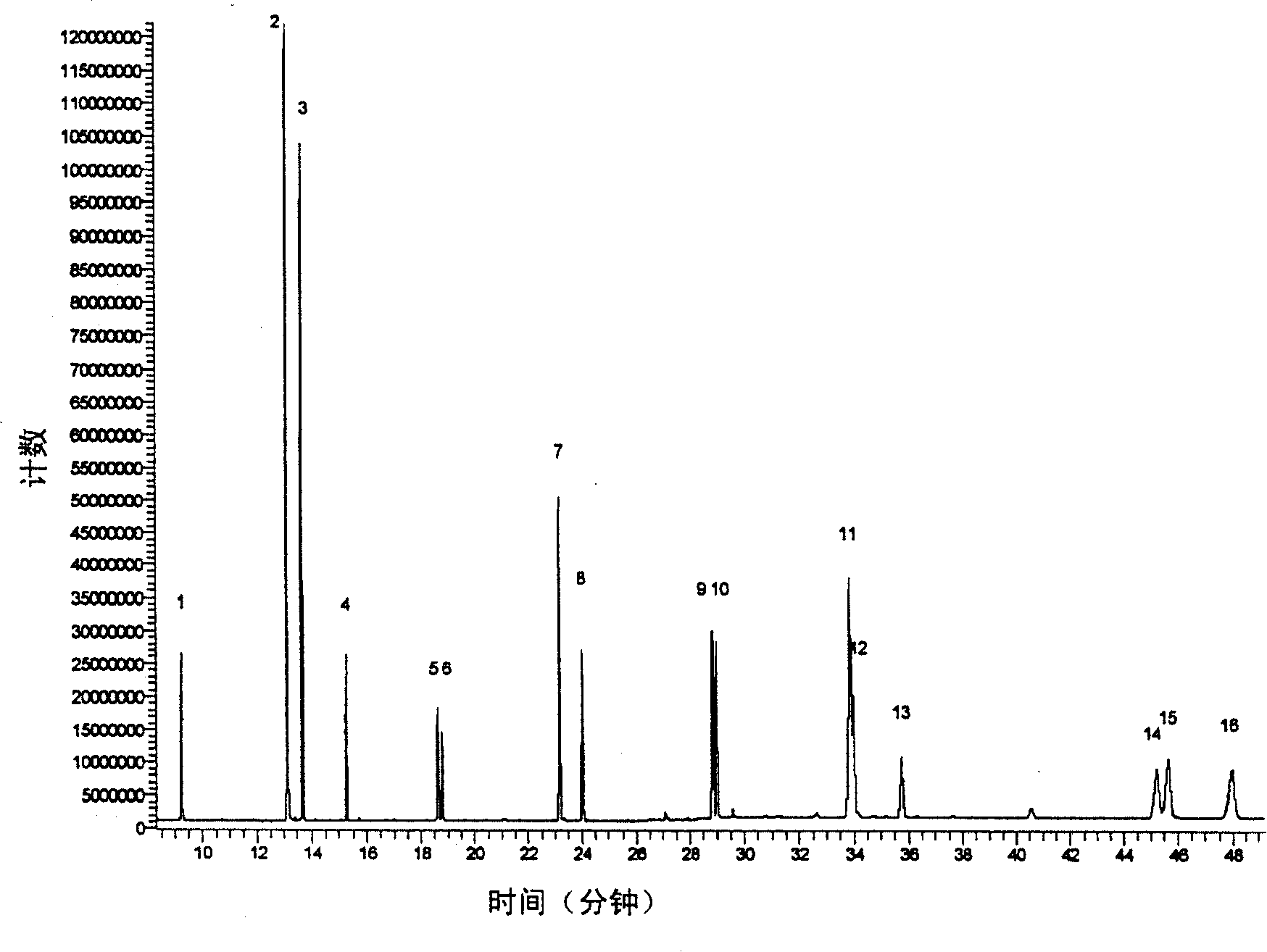

[0033] The standard sample of polycyclic aromatic hydrocarbons in water was extracted for 120 minutes with an adsorption stirring rod 2 with an extraction stationary phase film thickness of 100 μm, and then put into the inner liner 4 . Use the invented device to rise from room temperature to 280°C within 3 minutes and then perform chromatographic analysis after analyzing for 5 minutes. The purge gas and auxiliary gas are hydrogen, and the flow rates are 5mL and 1mL respectively. The analysis spectrum is as follows figure 2 shown.

Embodiment 3

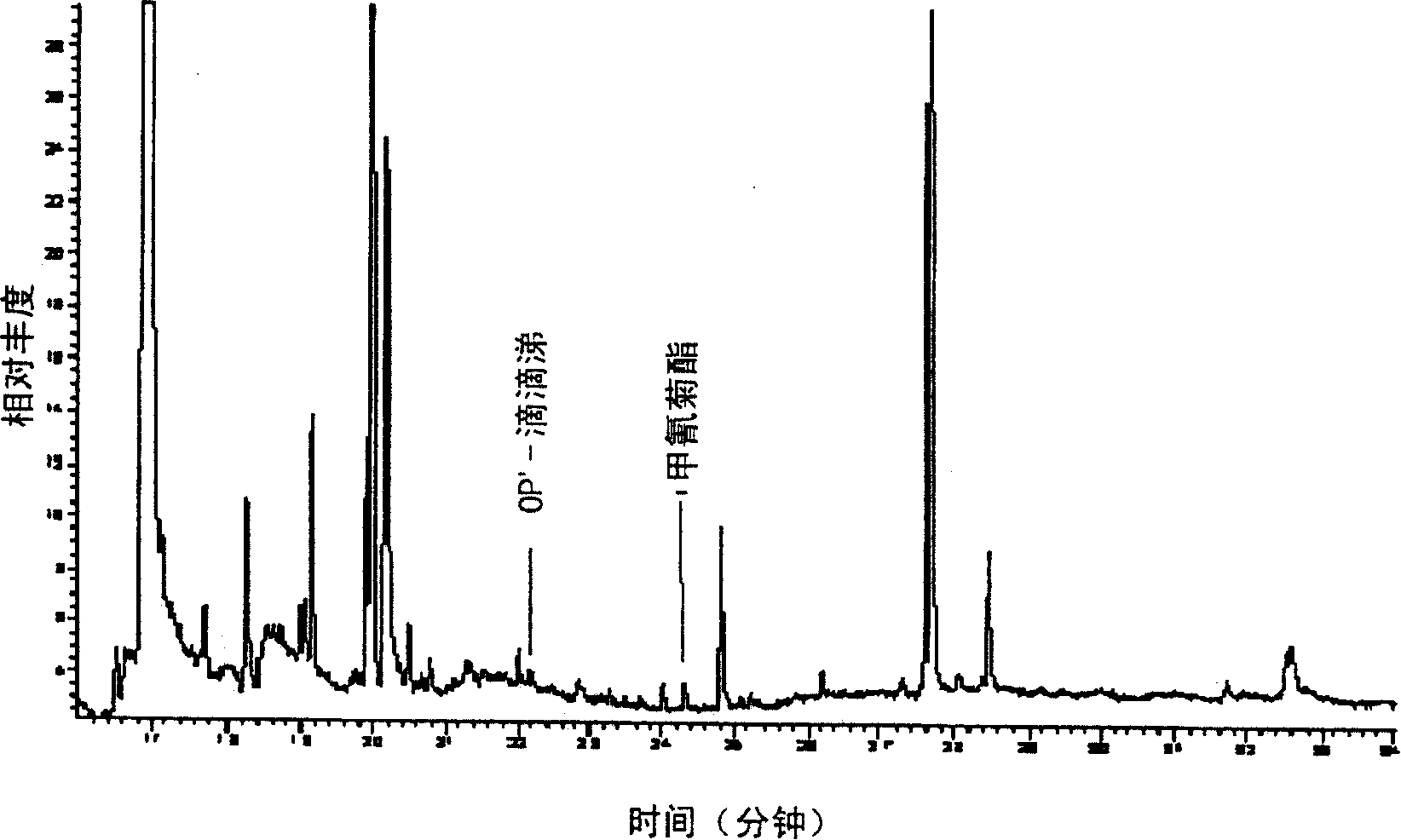

[0035] After extracting the pesticide residues in the tea leaves with an adsorption stirring rod 2 with an extraction stationary phase film thickness of 40 μm for 180 minutes, put it into the inner liner 4, use the device in this invention to heat up to 260 ° C within 3 minutes and analyze for 5 minutes Afterwards, chromatographic analysis was carried out, and the purge gas and auxiliary gas were helium, and the flow rates were 3mL and 1mL, respectively. The analyzed components enter the capillary gas chromatography-mass spectrometer for analysis and detection, and the analysis spectrum is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com