Technological method of partly submerged type platform complex K type node welding

A welding process and node technology, which is applied in the field of semi-submersible platform complex K-type node welding process, can solve the problems of complex K-type node welding process and K-type node welding reliability, so as to improve welding construction efficiency and improve welding efficiency. Accessibility, guaranteed penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

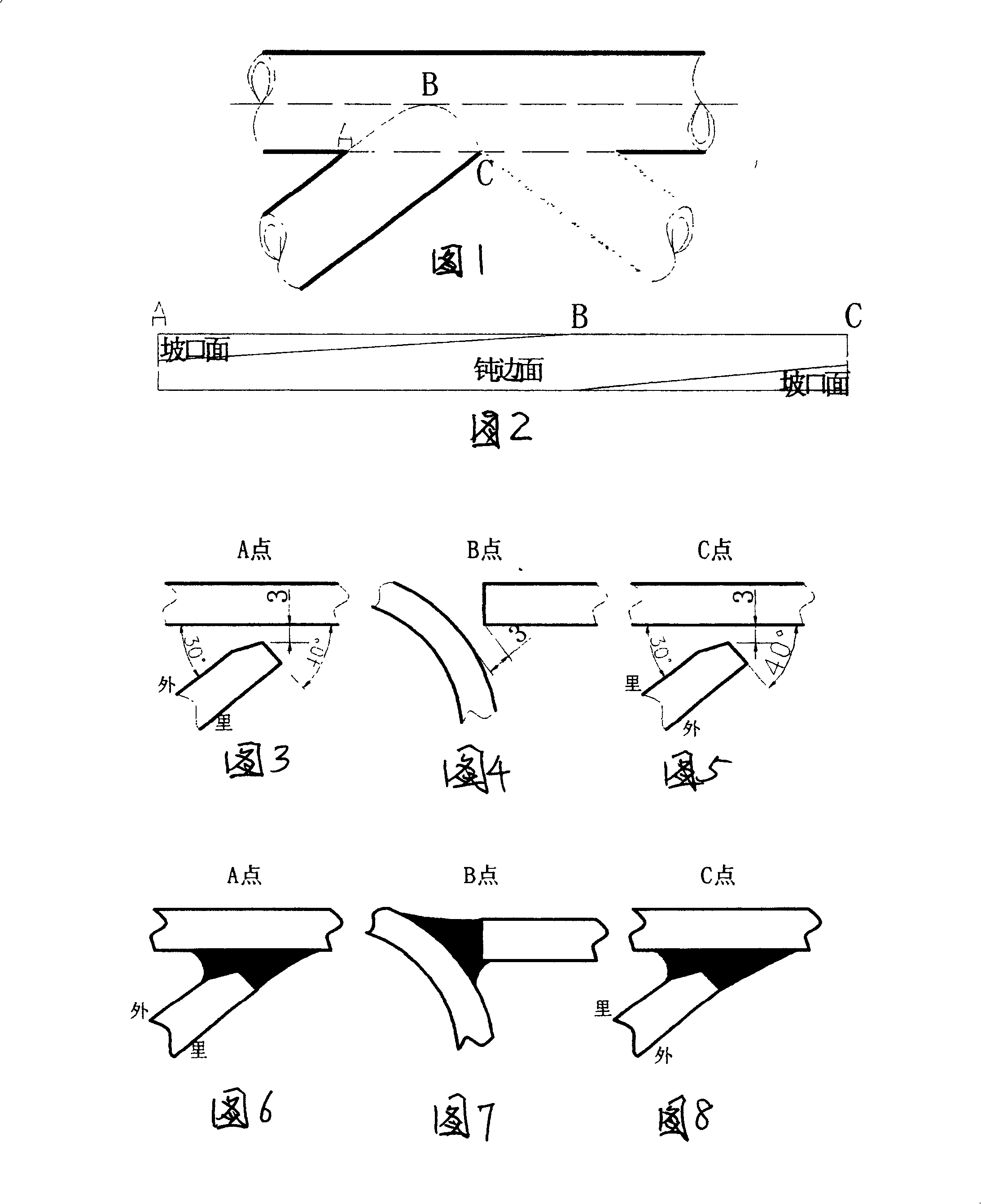

[0007] The complex K-type joint welding process method of this submersible platform of the present invention is used for the welding of BINGO 9000 submersible platform K-type joints in the exploration of deep sea oil / natural gas resources, and the three sections of pipes of the K-type joints are placed correspondingly (see Fig. 1 ), the circumference of the 30-degree oblique pipe joint is intersected with the outside of the transverse pipe. The welding groove of the oblique pipe adopts the form of variable angle and blunt edge in the whole circle of the joint of the intersecting line. To the upper and lower midpoints, it is the inner groove and gradually decreases from the maximum to zero; if it is the outer groove from the obtuse angle end A of the oblique pipe to the upper midpoint B, it is gradually reduced from the largest groove to zero, and from the acute angle of the oblique pipe From end C to upper middle point B, it is an inner bevel and gradually decreases from maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com