Image sensor and reader

An image sensing device and image information technology, applied in image communication, radiation control devices, televisions, etc., can solve problems such as the difficulty of designing CIS substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments to which the present invention is applied will be described in detail with reference to the drawings.

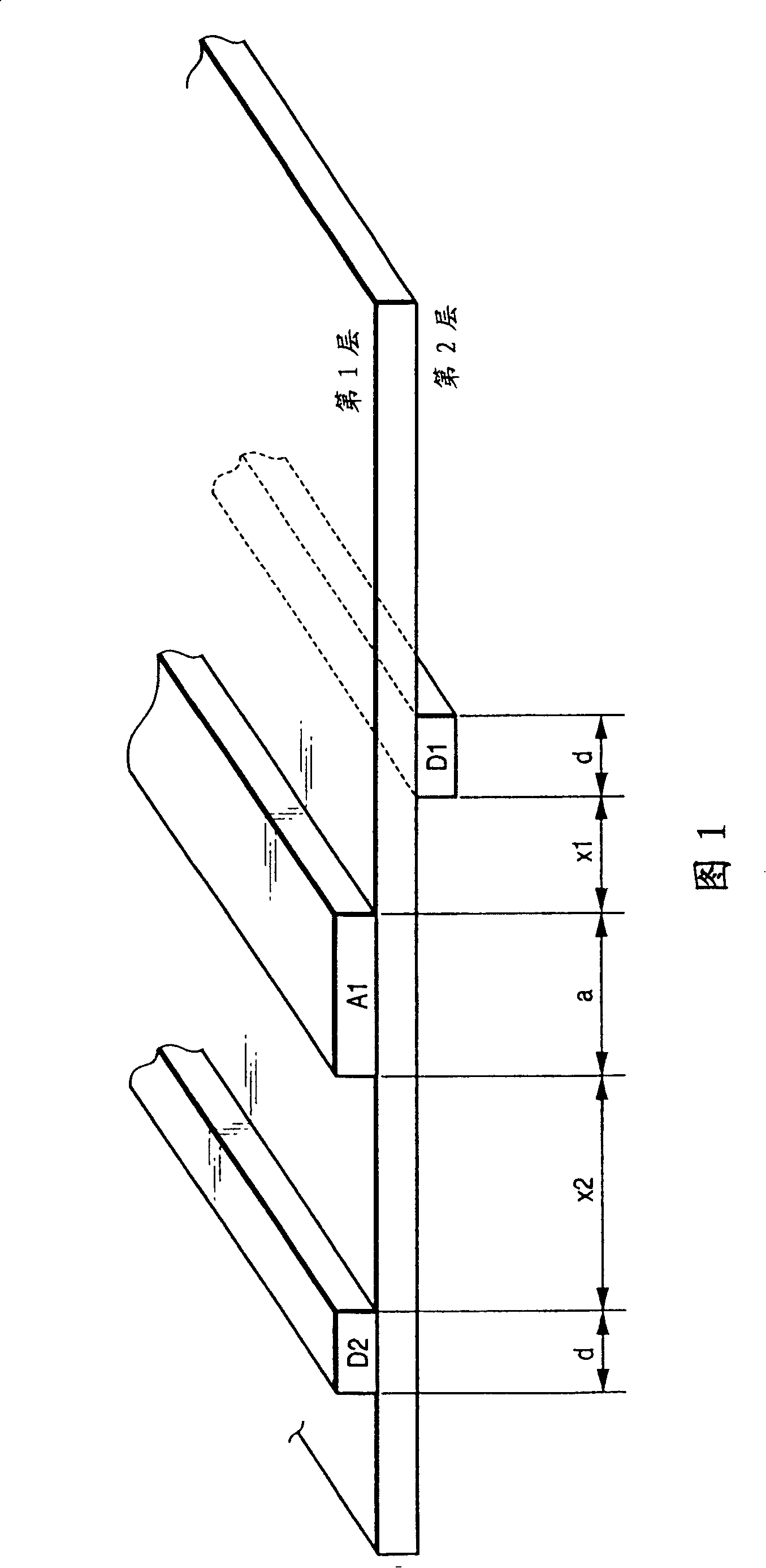

[0024] 1. The overall structure of the close-fitting image sensor

[0025] The overall structure of the adhesive image sensor used in this embodiment will be described with reference to FIG. 4 .

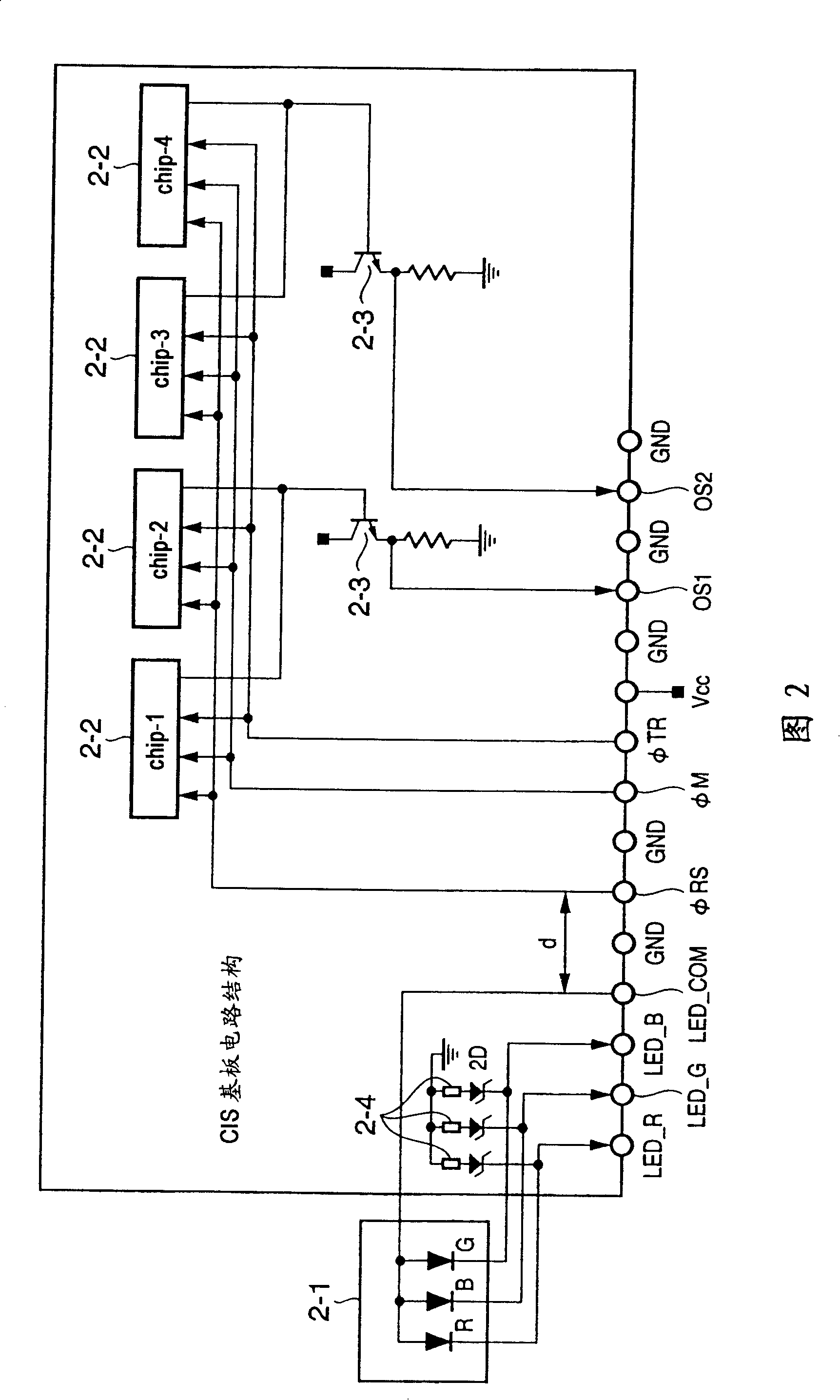

[0026] 4-1 is a linear light source unit, a light guide 4-1-2 that uniformly diffuses the light emitted from the light source unit along the reading main scanning direction by the LED light source unit 2-1 arranged at the end of the light source unit constitute.

[0027] The irradiated light irradiated from the light guide 4-1-2 is reflected by the original on the original glass, and the reflected light passes through the self-focusing lens array 4-2 to the photosensitive element (CCD) 2-3 fixed on the substrate 4-3. on the imaging.

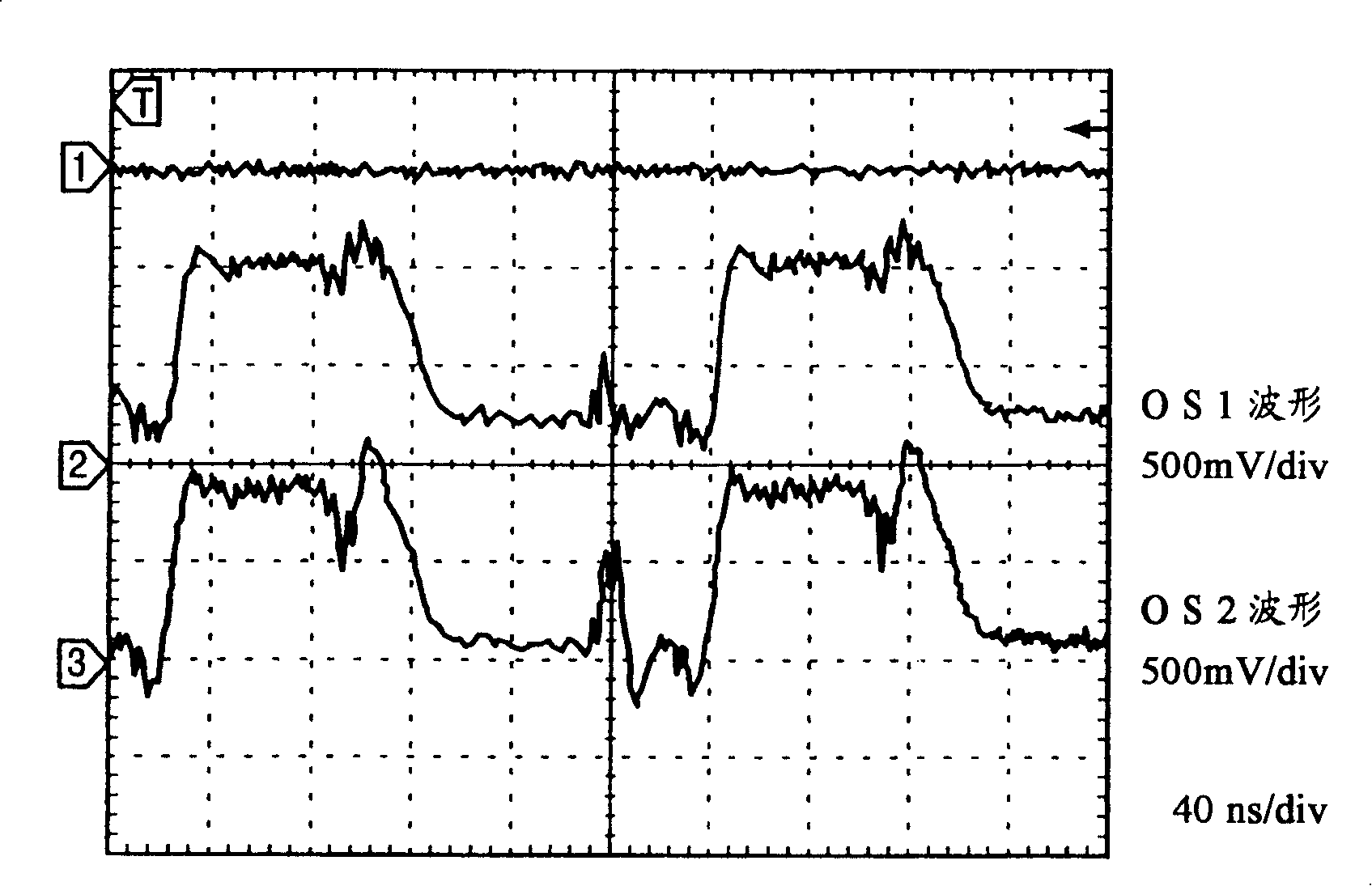

[0028] The imaged light is photoelectrically converted by CCD2-3, and sequentially output as image signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com