Electromagnetic noise suppressor, article with electromagnetic noise suppression function, and their manufacturing methods

A technology of noise suppression and electromagnetic wave, applied in the direction of magnetic objects, circuits, magnetic materials, etc., can solve the problems of light weight, large thickness of electromagnetic wave interference suppression body, and inability to meet high-density assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

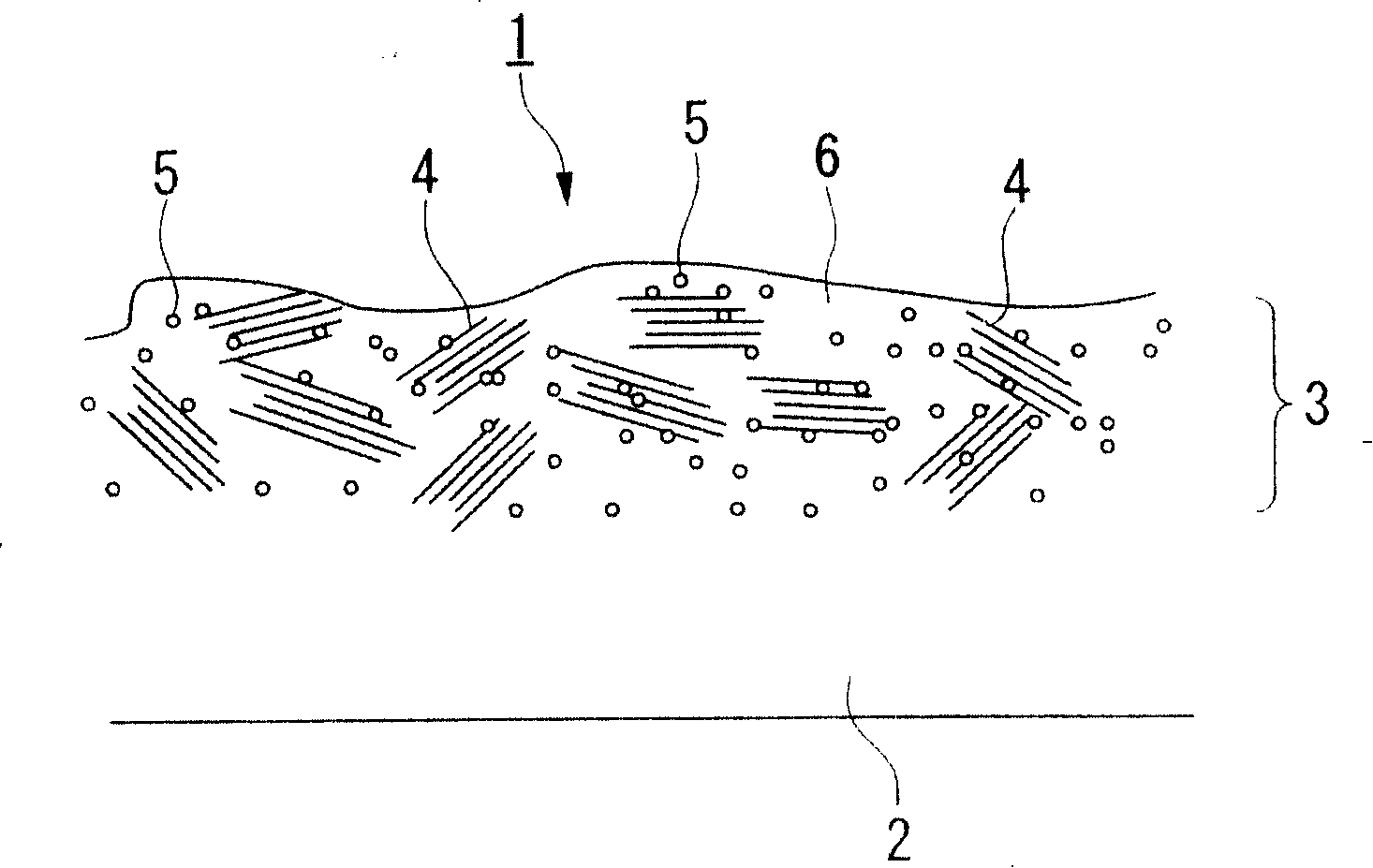

[0285] The base is 12μm thick polyethylene terephthalate film (hereinafter referred to as PET) (shear modulus of 3.8×10 9 (Pa), the carbon dioxide transmittance is 1×10 -11 [cm 3 (STP)cm / (cm 2 ×s×cmHg)], the average surface roughness is 1.8μm), the Mn-Zn high-permeability ferrite with a converted film thickness of 3nm is sputtered by opposing target magnetron sputtering to form a composite Floor. The surface resistance of the composite layer was measured with great care by the DC 4-terminal method. In addition, the film was adjusted to the desired size, a polyester adhesive was inserted in the middle of ten films and laminated, and they were integrated by vacuum press molding to obtain an electromagnetic noise suppressor with a total thickness of 138μm. . Next, the specific gravity and electromagnetic wave noise suppression characteristics were measured. The results are shown in Table 1.

Embodiment 2

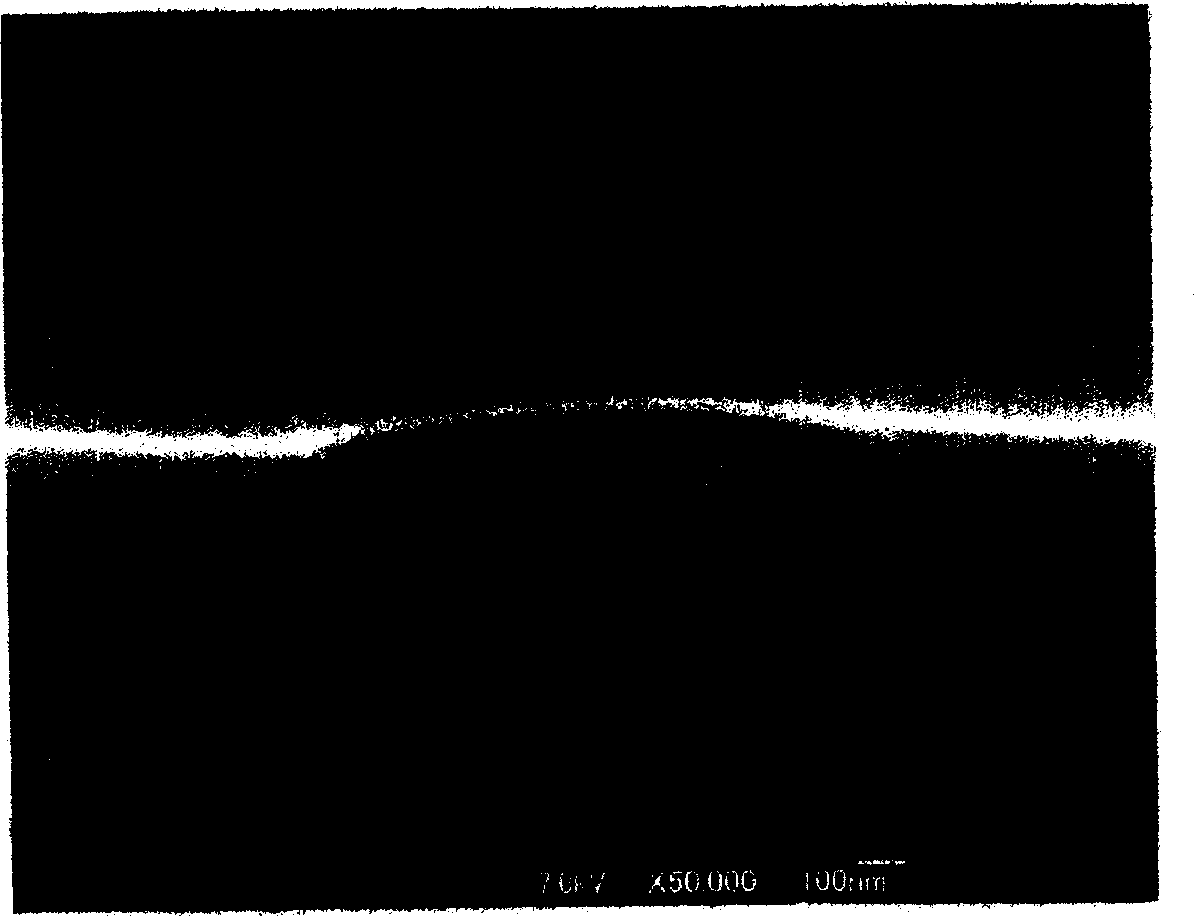

[0287] On a PET film with a thickness of 25 μm as a support layer, a silicon (oxygen) rubber with a thickness of 20 μm as a substrate (shear modulus of 1×10 7 (Pa), carbon dioxide transmittance is 2.2×10 -7 [cm 3 (STP)cm / (cm 2 ×s×cmHg)]), on which a Fe-Ni-based soft magnetic metal with a film thickness of 20 nm converted to a film thickness of 20 nm was sputtered to form a composite layer by the magnetron sputtering method on the opposite target. The surface resistance of the composite layer was measured with great care by the DC 4-terminal method. In addition, the film was adjusted to a desired size to obtain an electromagnetic wave noise suppressor having a total thickness of 45 μm. Next, the specific gravity and electromagnetic wave noise suppression characteristics were measured. The results are shown in Table 1.

Embodiment 3

[0289] On a PET film with a thickness of 25 μm as a support layer, a polyurethane gel with a thickness of 10 μm as a substrate (shear modulus of 1.7×10 6 (Pa), carbon dioxide gas transmittance is 5.3×10 -8 [cm 3 (STP)cm / (cm 2 ×s×cmHg)]), on which a composite layer was formed by sputtering a Fe-Si-Al-based soft magnetic metal with a film thickness of 15 nm converted by a magnetron sputtering method (non-opposing target type). The surface resistance of the composite layer was measured with great care by the DC 4-terminal method. Furthermore, a 2 μm polyurethane gel was coated on the composite layer and sputtered again. By repeating this process, three composite layers were set to obtain an electromagnetic wave noise suppressor with a total thickness of 79 μm. Next, the specific gravity and electromagnetic wave noise suppression characteristics were measured. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com