Preparation technique of absorbent hydroxyapatite artificial bone

A hydroxyapatite and preparation process technology, which is applied in medical science, prosthesis and other directions, can solve the problems of high requirements on corrosion resistance of the reactor, unsatisfactory treatment effect, harsh reaction conditions, etc., and achieves remarkable medical effect, Light weight and the effect of expanding the hole surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

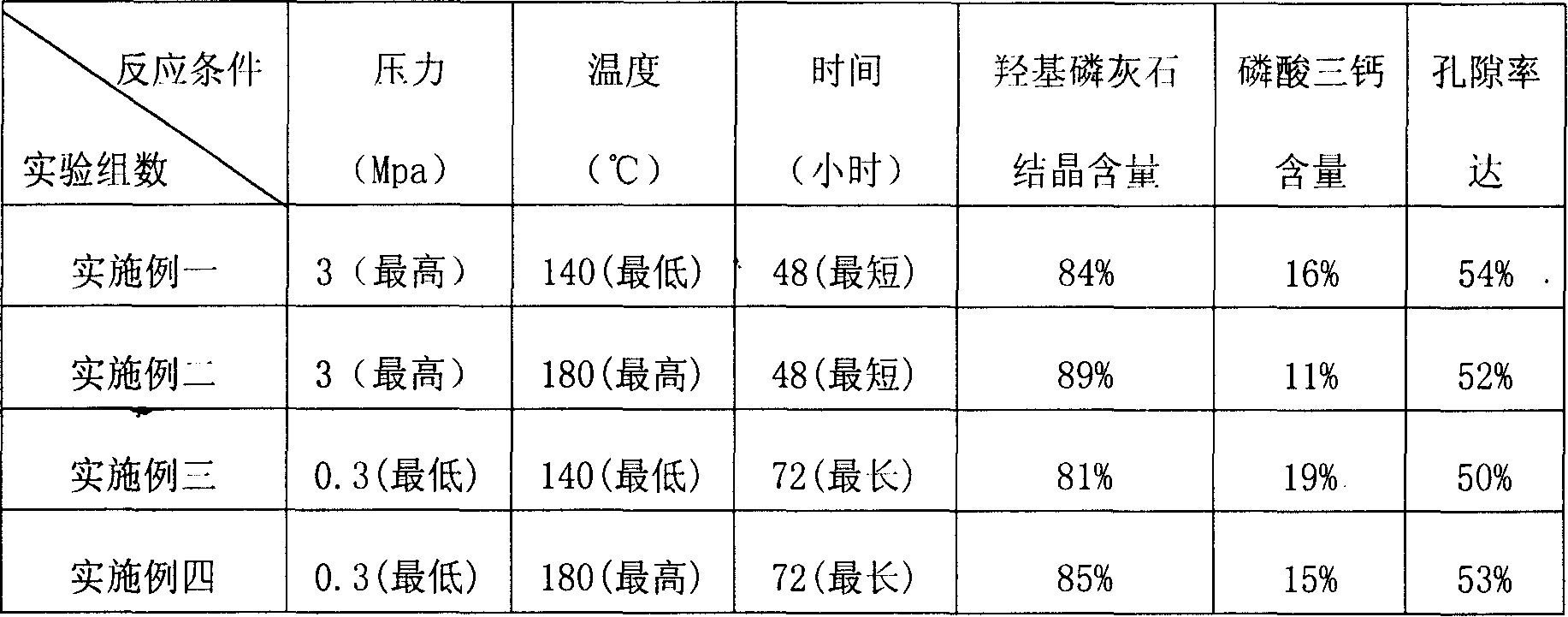

[0016] Embodiment 1: 1. Get 2 kilograms of natural corals, soak them in fresh water for two days, grind them into shape with an electric sand wheel, soak them in tap water for one day to remove organic matter, and scrub the surface to remove organic matter in the corals. ② Use 10 kg of 0.001% dilute hydrochloric acid to etch the coral channel to make the surface of the channel rough. Measure the diameter of the channel under an optical microscope and control it at about 200 μm. ③Take 2 kg of saturated diammonium hydrogen phosphate salt solution to soak the coral, and place it in a 5 kg chemical synthesizer (reactor), and react in the synthesizer at 140°C for 48 hours under a pressure of 3Mpa to obtain a composite Artificial bone. ④ The product is microwave-dried for 30 minutes, packed in double-layer plastic bags, and then sterilized with high-energy gamma rays 600rad after sealing.

[0017] Experiments show that: under the highest pressure (3Mpa) and the lowest temperature (...

Embodiment 2

[0018] Example 2: ①②④ are the same as in Example 1, and ③reaction conditions are changed to 180°C for 48 hours under a pressure of 3Mpa to obtain an artificial bone.

[0019] Experiments show that under the highest pressure (3Mpa) and highest temperature (180°C), the coral replacement reaction is carried out in the shortest time (48 hours). The artificial bone contains 89% of coral hydroxyapatite crystals, triphosphate Calcium 11%, porosity reaches 52%.

Embodiment 3

[0020] Example 3: ①②④ are the same as in Example 1, ③reaction conditions are changed to 140° C. for 72 hours under a pressure of 0.3 MPa.

[0021] Experiments show that under the lowest pressure (0.3Mpa) and the lowest temperature (140°C), the coral replacement reaction takes the longest time (72 hours). The artificial bone contains 81% of coral hydroxyapatite crystals, Tricalcium phosphate 19%, porosity reaches 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com