Double-chamber atomizer

An ultra-fine pulverizer and pulverizing knife technology, which is applied in grain processing and other directions, can solve the problems of unreasonable material flow in the screening system and the position of the hammer hitting the material, the superfine pulverizer is a fly in the ointment, and the material distribution is uneven. The effect of crushing, force balance, and improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

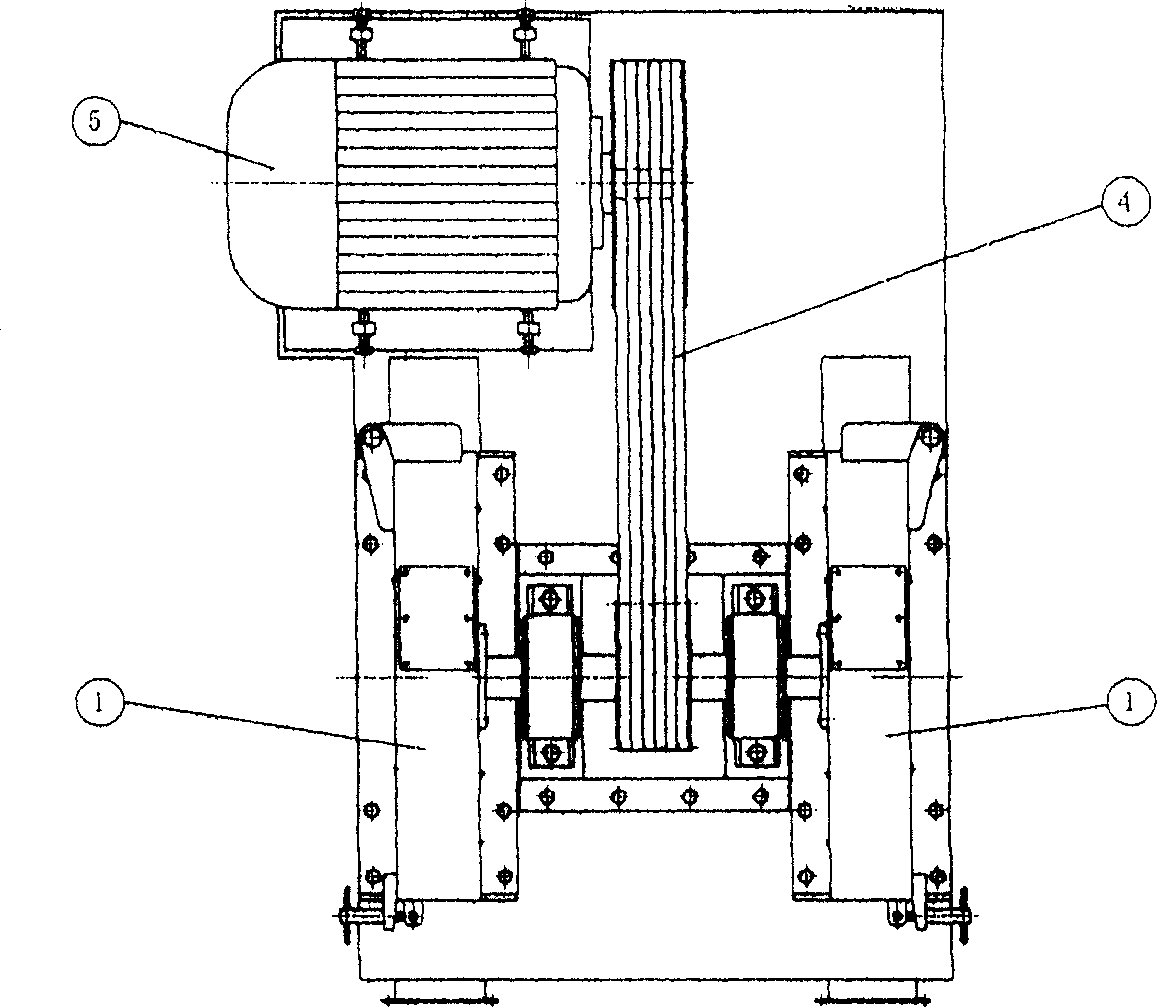

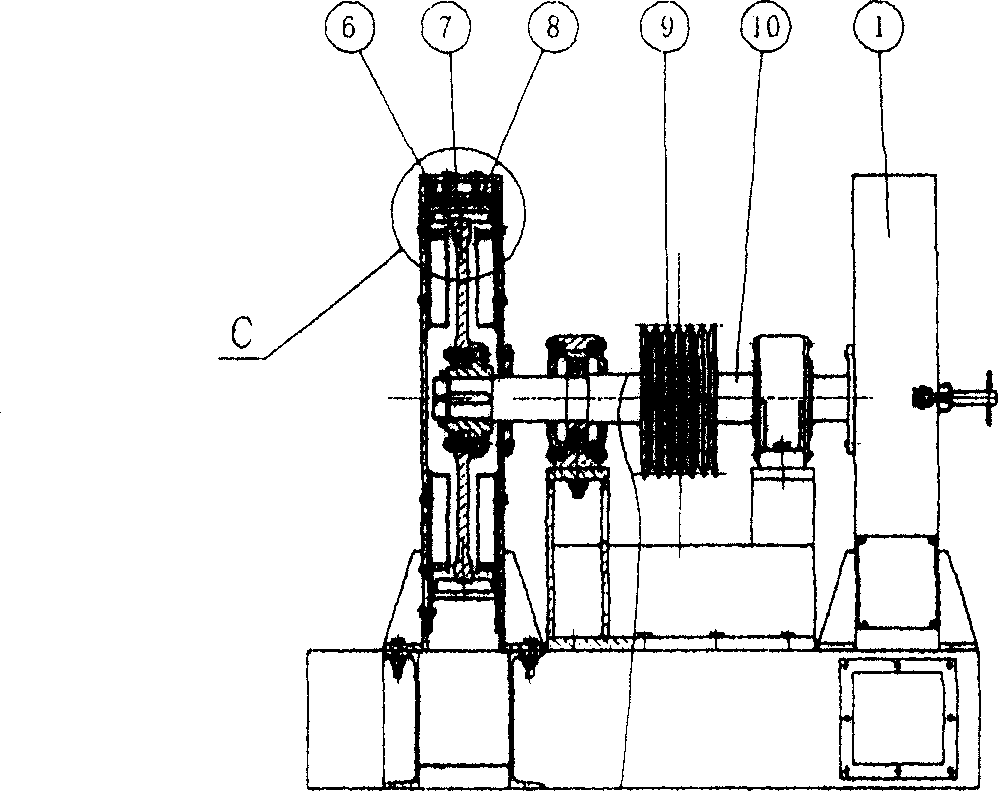

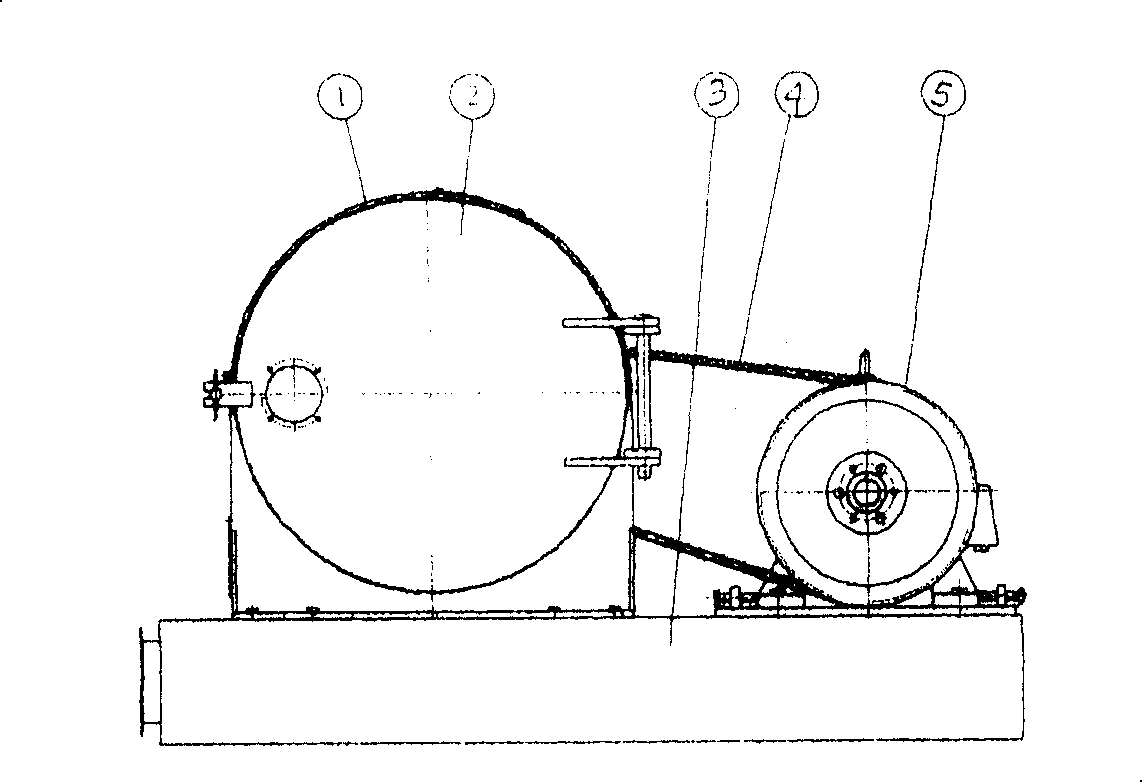

[0026] according to figure 1 , 2 , 3, 4, and 5, the present invention has an organic base 3, a motor 5 is fixed on the base 3, and the motor 5 is connected to the pulley 9 through the belt 4, and the pulley 9 is respectively fixed with a super-dimensional on both sides of the pulley 9 through the main shaft 10. Pulverizer, superfine pulverizer organic casing 1, is fixed with the cutter head 6 coaxial with belt pulley 9 in the casing 1, and the cutter head 6 edge place has the crushing knife 7 that is fixed by a certain distance interval. On the casing 1 at the periphery of the circumference of the comminuting knife 7, a section of tooth plate 8 is fixed with the teeth of the cutter head 6 and inclined oppositely to its direction of rotation. There is a sieve plate 11, and the two ends of the sieve plate 11 and the tooth plate 8 are joined together to form a circular wall outside the pulverizer. A door cover 2 is arranged on an outer wall of the casing 1 .

[0027] According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com