Combined machine set for tillage seeding machine and corn harvesting seeding machine

A seeder, operation technology, applied in crop processors, fertilizers and seeding equipment, agricultural machinery and implements, etc., can solve problems such as clogging openers, inability to solve, and long body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

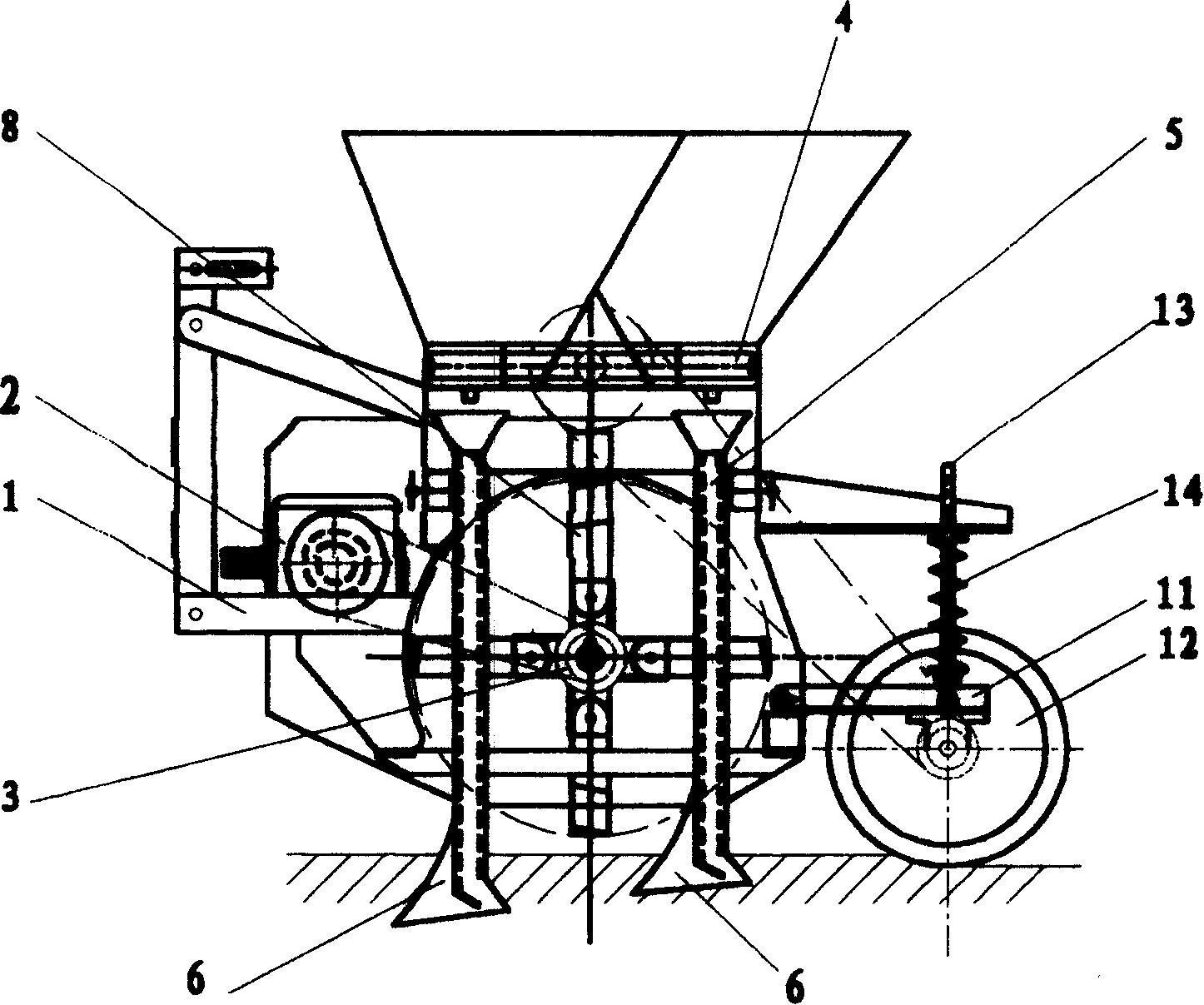

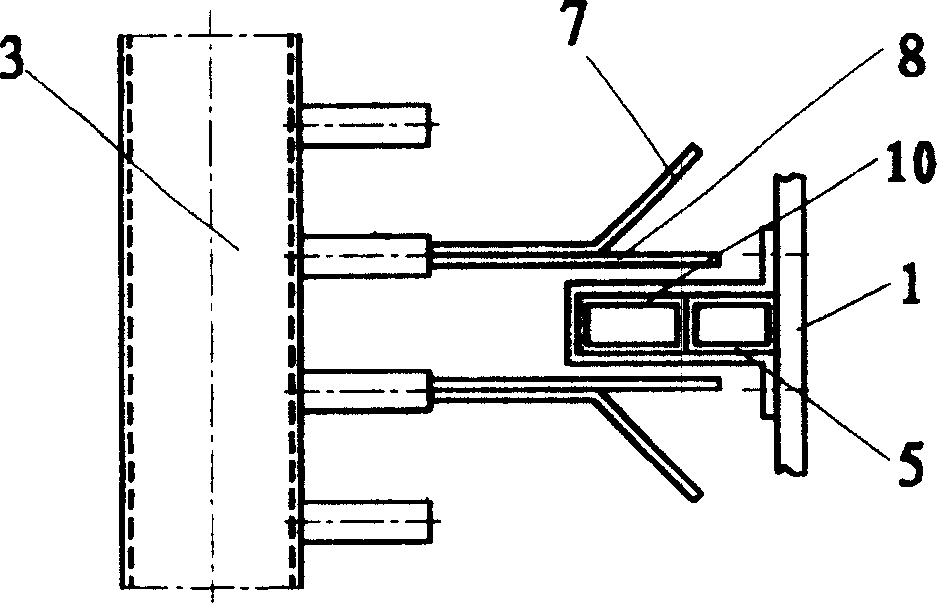

[0014] Embodiment 1, as attached figure 1 The shown roller acts as a compound operation no-tillage seeder for straw crushing. It is mainly suitable for sowing wheat after autumn corn harvest, and can also be used for sowing corn after summer harvest. A suspension mechanism and a gear box 2 connected with the tractor are installed on the frame 1. The gear box is similar to the existing structure, that is, the power of the tractor is transmitted to the gear box 2 through the transmission shaft, and the gear box changes the speed and direction of the transmission shaft. The output shaft of the gear box is transmitted to the roller 3 installed on the frame 1 through a belt or a chain. Roller 3 is equipped with straw crushing knife 7. Seed discharge mechanism 4 is installed on the frame of the top of roller, and seed case is arranged above, and seed delivery pipe 5 is connected below the seed discharge mechanism. The seed pipe 5 can be a hollow profile, and the ditch opener 6 is...

Embodiment 2

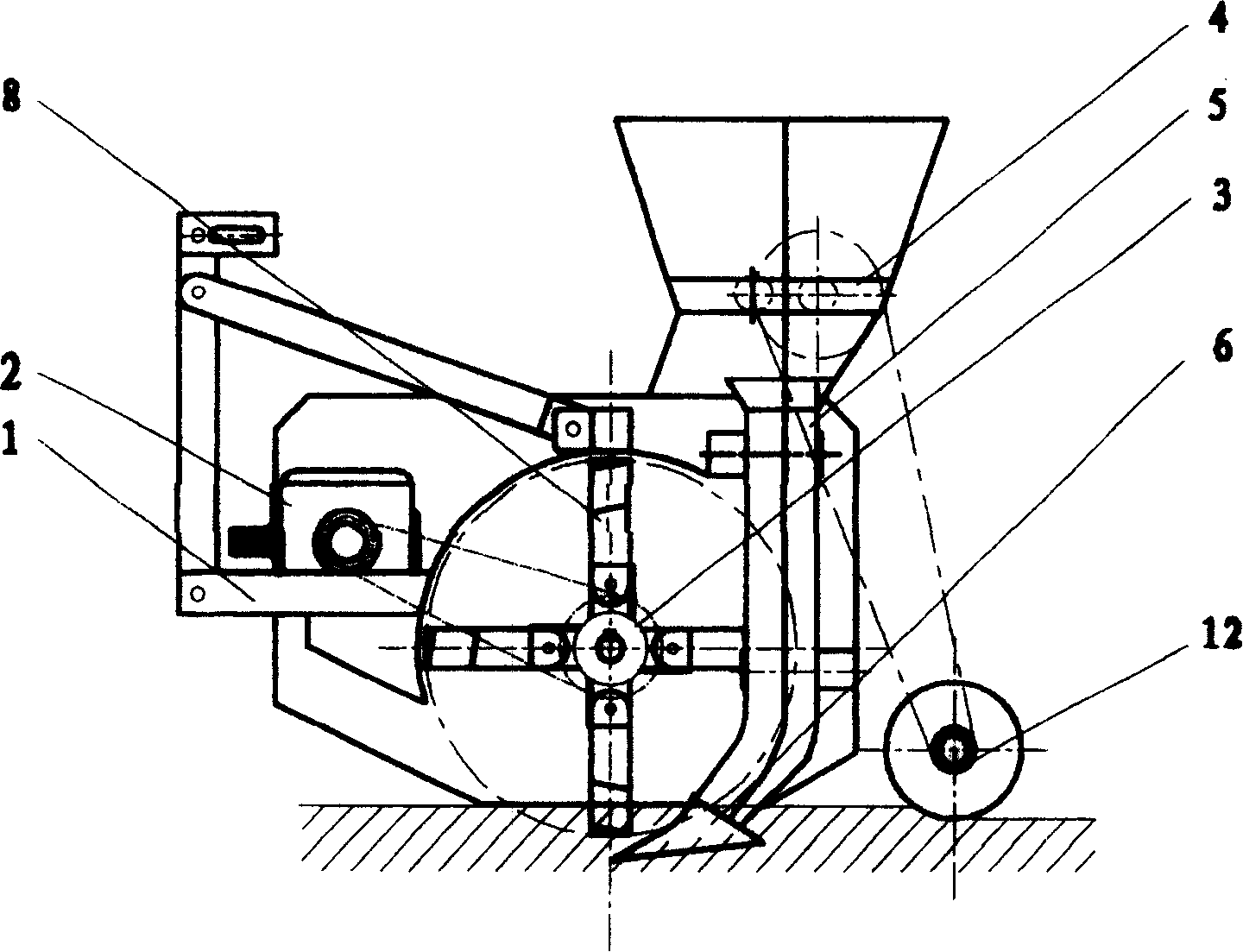

[0015] Embodiment 2, as attached figure 2 Combined planter with the roller as shown. Mainly used in summer sowing, it can figure 1 The compound seeder shown in the figure is refitted, the rotation speed of the roller is reduced through the gear box, the straw crushing knife is replaced with a sieve knife, the seeding mechanism 4 is adjusted to the state of sowing corn, and the row spacing is also adjusted, so that the stalk can be sown . The depth of entry into the soil can be adjusted, and it can also prevent the openers from being entangled in grass and achieve the effect of no-tillage sowing.

Embodiment 3

[0016] Embodiment 3, with Figure 5 The shown corn harvesting, straw crushing, sowing and fertilizing combined operation unit. The corn harvesting head 01 is hung in front of the tractor 02 to complete the ear picking of the corn, and the ear is transported to the back of the tractor by the elevator 03 and falls into the ear box 04. The compound operation sowing and fertilizing machine of the present invention is suspended below the ear box at the back of the tractor to form a corn harvesting, sowing and fertilizing combined operation unit. After the front corn harvester has picked the ears, the stalks are squeezed and become soft and lodging. The straw crushing knife installed on the roller of the so-called compound operation seeder and fertilizer machine crushes these straws and returns them to the field, and at the same time passes them through the rollers. The Miscellaneous Discharging Knife overcomes the clogging phenomenon of straw and weeds, and completes the fertiliza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com