Refrigerant compressor

A refrigerant and compressor technology, applied in additives, mechanical equipment, machines/engines, etc., can solve the problems of exhaust reed seal failure and poor compression, and achieve high reliability and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

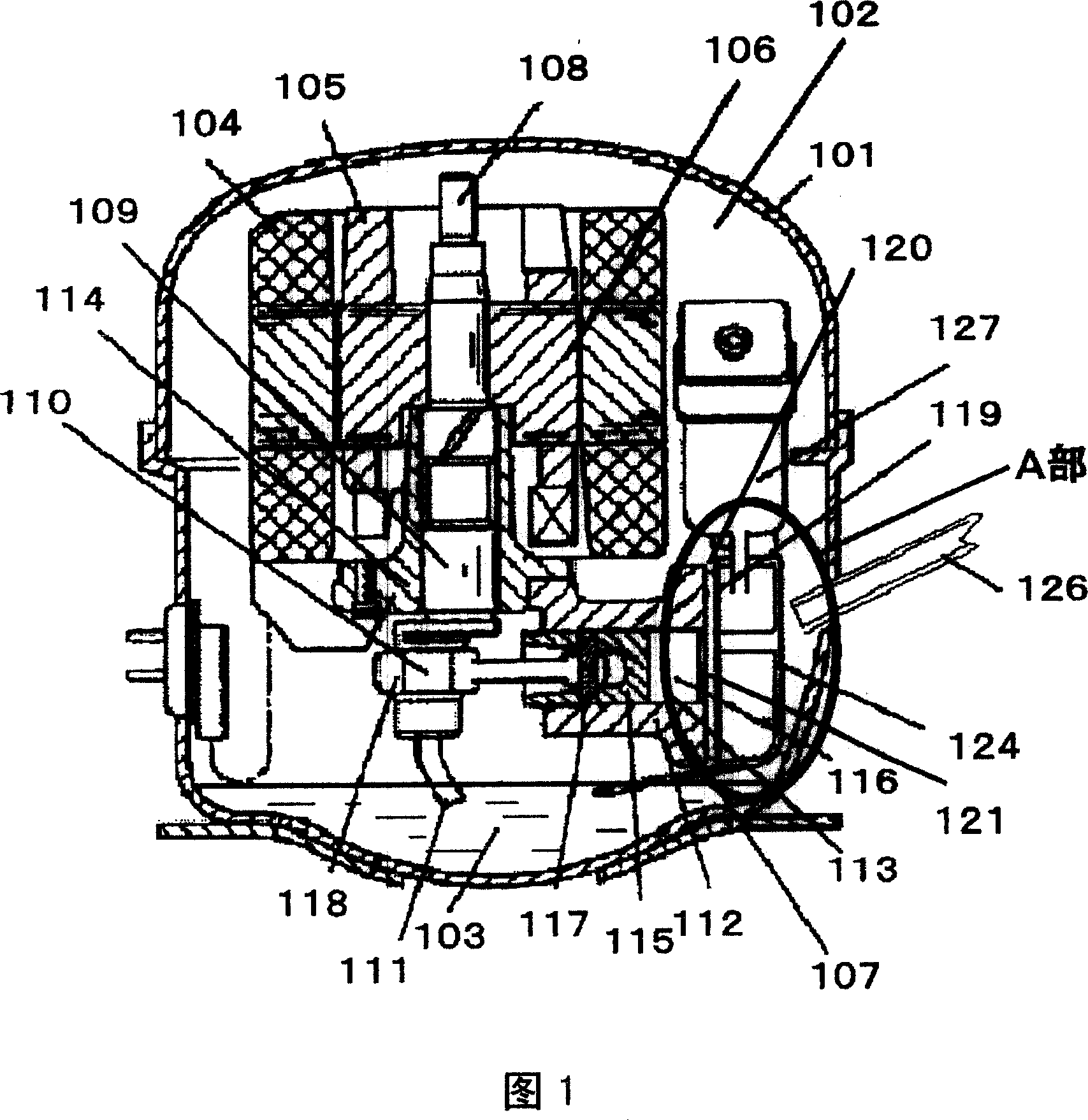

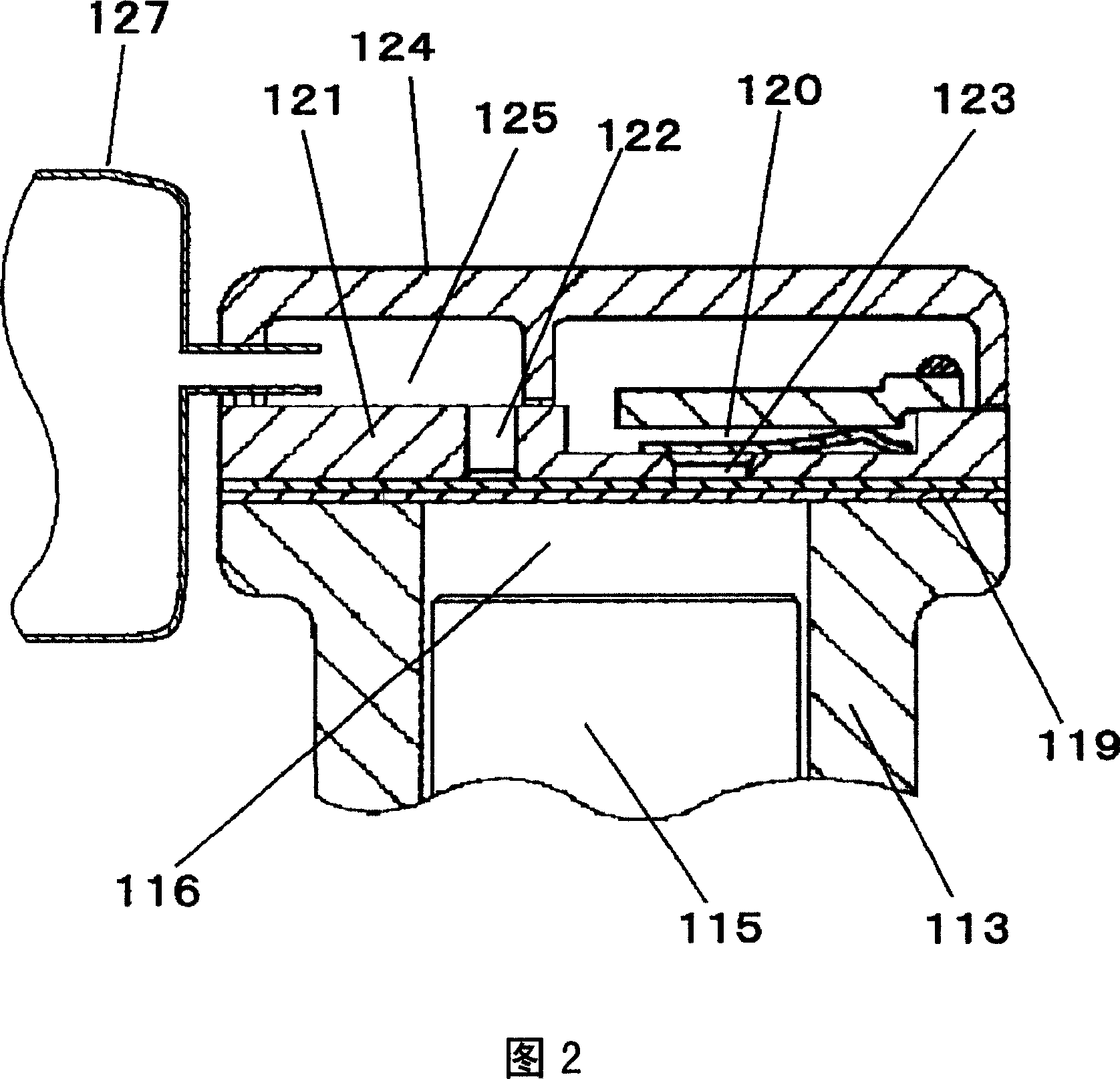

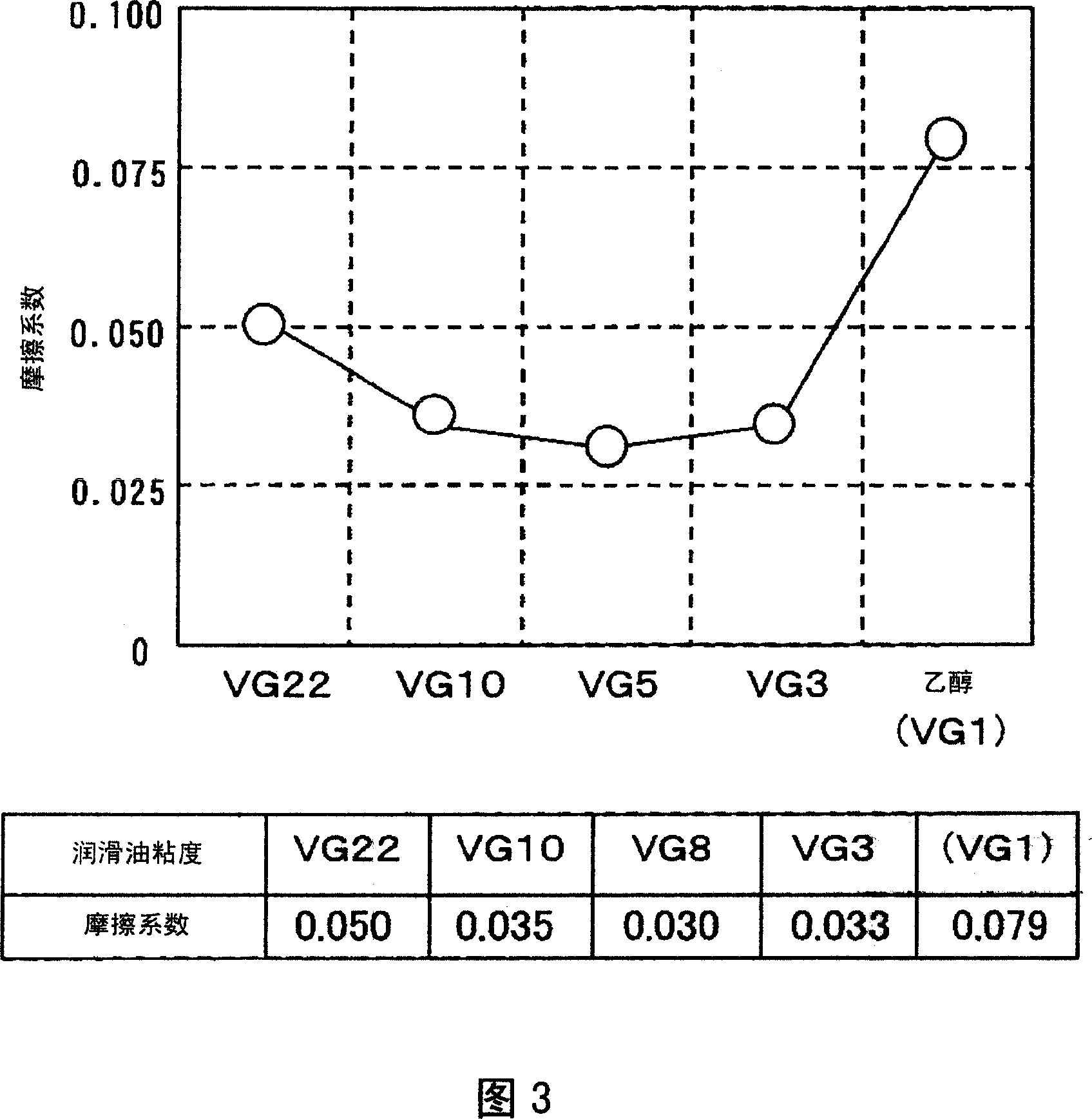

[0049] Fig. 1 is a cross-sectional view of a refrigerant compressor in Embodiment 1 of the present invention, Fig. 2 is an enlarged schematic diagram of part A in Fig. 1 , and Fig. 3 is a schematic diagram of friction coefficient characteristics under different lubricating oil viscosities, Fig. 4 is a schematic diagram of compressor efficiency characteristics under different lubricating oil viscosities.

[0050] In Fig. 1, the interior of the sealed casing 101 is filled with a refrigerant gas 102 composed of R600a, and at the same time, lubricating oil composed of mineral oil 103 with a VG of 5 is stored at the bottom, and the boiling point is 350°C or higher. The volume ratio is 10% to 30%, and the volume ratio of components with a boiling point of 300°C or lower is 50% to 70%. In addition, a motor mechanism 106 composed of a stator 104 and a rotor 105 and a reciprocating compression mechanism 107 driven by the motor mechanism 106 are installed in the sealed housing 101 .

...

Embodiment 2

[0081] Fig. 5 is a schematic diagram of the refrigerant compressor in this embodiment, Fig. 6 is an enlarged schematic diagram of part A in Fig. 5, Fig. 7 is a sectional view of B-B in Fig. 5, and Fig. 8 is a schematic diagram of some important structures in Fig. 7 The schematic diagram is enlarged, and Fig. 9 is a graph showing the extraction characteristics of oligomers under different lubricating oil viscosities.

[0082] As shown in FIGS. 5-8 , lubricating oil 202 is stored in the sealed case 201 , and these lubricating oils 202 are composed of a single mineral oil with substantially the same evaporation temperature, and its viscosity is V65. Meanwhile, a compression mechanism 203 used as a compression component and a distributed winding induction motor 204 used as an electric mechanism to drive the compression mechanism 203 are also provided in the sealed casing 201 . In addition, the refrigerant used is R600a.

[0083] The motor 204 is wound with a main winding 205 thro...

Embodiment 3

[0099] Fig. 10 is a schematic diagram of the refrigerant compressor in this embodiment, Fig. 11 is an enlarged schematic diagram of part C in Fig. 10, Fig. 12 is a D-D sectional view of Fig. 10, and Fig. 13 is a diagram of some important structures in Fig. 12 Zoom in on the schematic.

[0100] As shown in Fig. 10 and Fig. 11, a lubricating oil 302 with a viscosity of VG8, which is composed of a single mineral oil with substantially the same evaporation temperature, is stored in the sealed housing 301, and a compression mechanism 303 is also provided to drive the compression mechanism. 303 of the electric motor 304 . The motor 304 is a concentrated winding frequency converter motor. The refrigerant used is R600a.

[0101] In the motor 304, the main winding 305 through which current supplied from a commercial power source (not shown) through a power supply circuit (not shown) flows is wound so as to pass between adjacent coil slots 307 (Fig. 12). The insulator 333 is inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com