Compound chamois nap decorated fabric and mfg. method

A technology for decorative fabrics and manufacturing methods, applied in the direction of textile decoration, textiles and papermaking, etc., can solve the problems of fabric strength decline, etc., to achieve improved coverage, increased tensile breaking strength and flat stiffness, elongation and air permeability moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

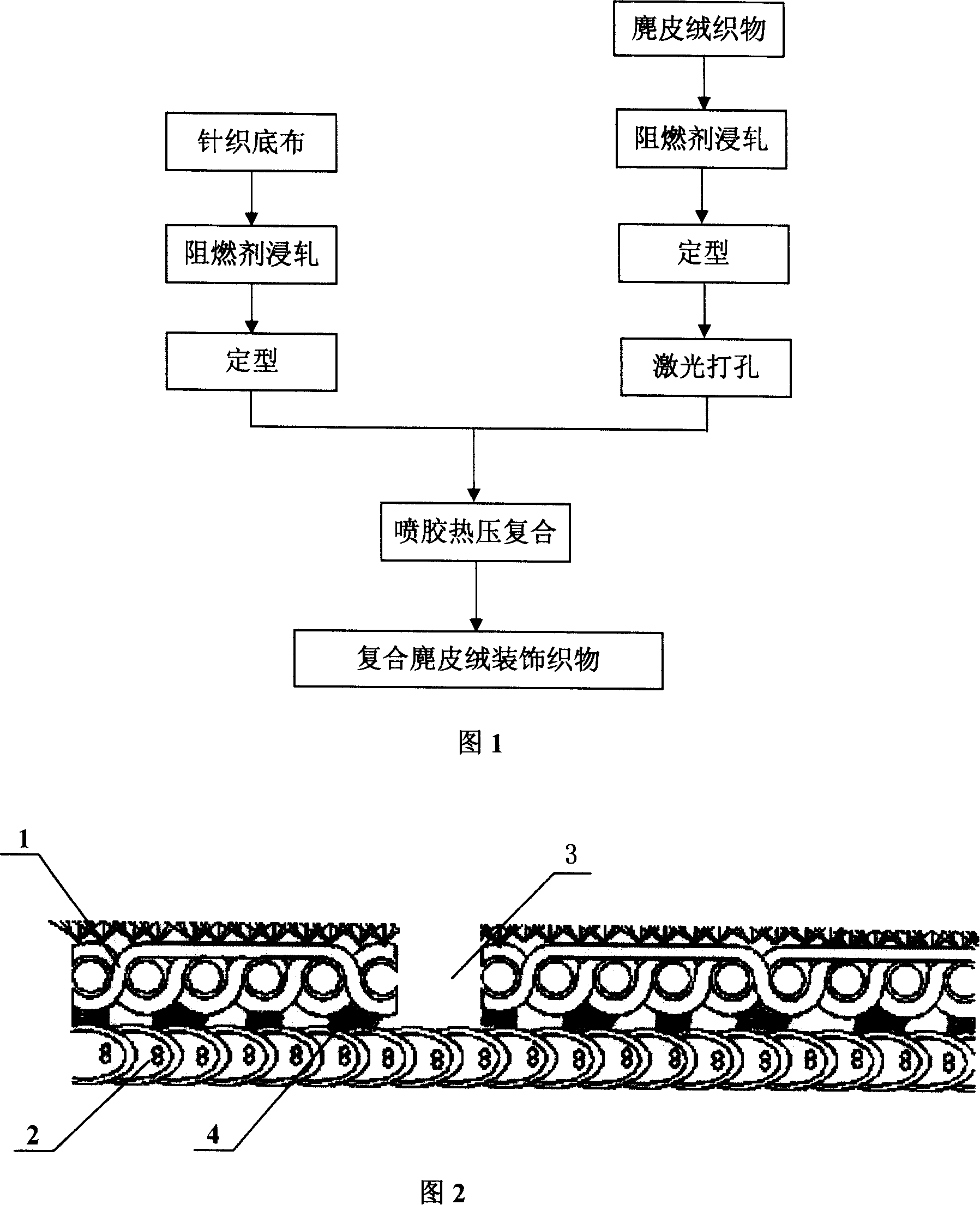

[0020] Embodiment 1: See accompanying drawing 1 and shown in accompanying drawing 2, a kind of composite suede decorative fabric, comprises the surface layer 1 that adopts suede fabric and fabric bottom layer 2, and the described surface layer 1 is distributed with penetrating surface The decoration hole 3 of the layer 1, the surface layer 1 and the bottom layer 2 are bonded by the adhesive 4 distributed in scattered dots.

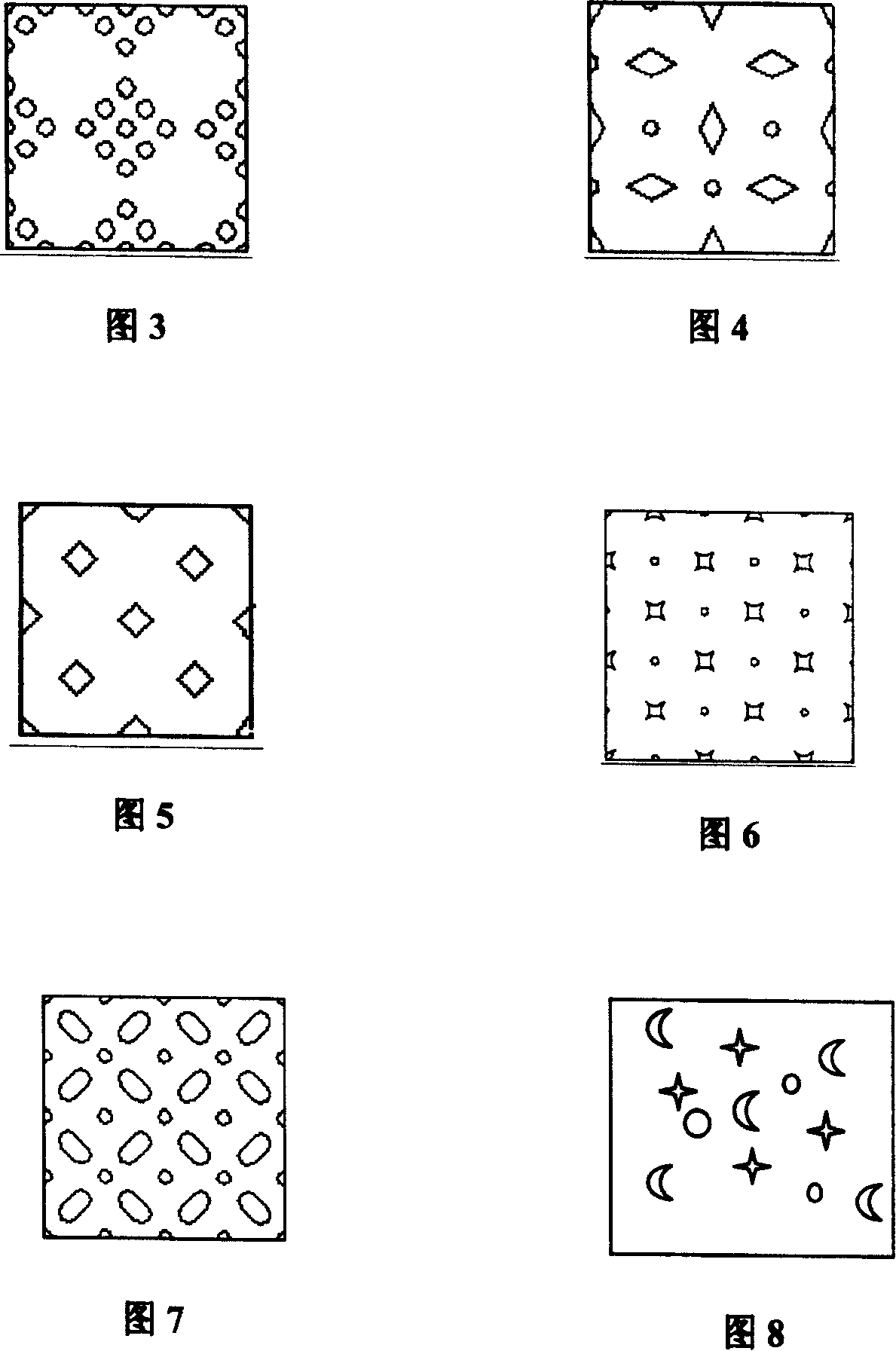

[0021] In this embodiment, the sea-island type composite superfine polyester suede fabric is used for the surface layer, and the T / C knitted base fabric is used for the bottom layer. The materials of the surface layer and the bottom layer are respectively dipped and rolled with a flame retardant after dyeing and before being shaped, for flame retardant treatment, and then shaped after burning, so that both the surface layer and the bottom layer materials have a flame retardant function. Using a fully computerized program-controlled laser precision hole cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com