Component structure of deposition chamber

A technology of component structure and deposition chamber, applied in the field of deposition chamber, can solve the problems of lower qualification rate, inclination, difficult positioning of subsequent processes, etc., to achieve the effect of improving the qualification rate and reducing the probability of wafer rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

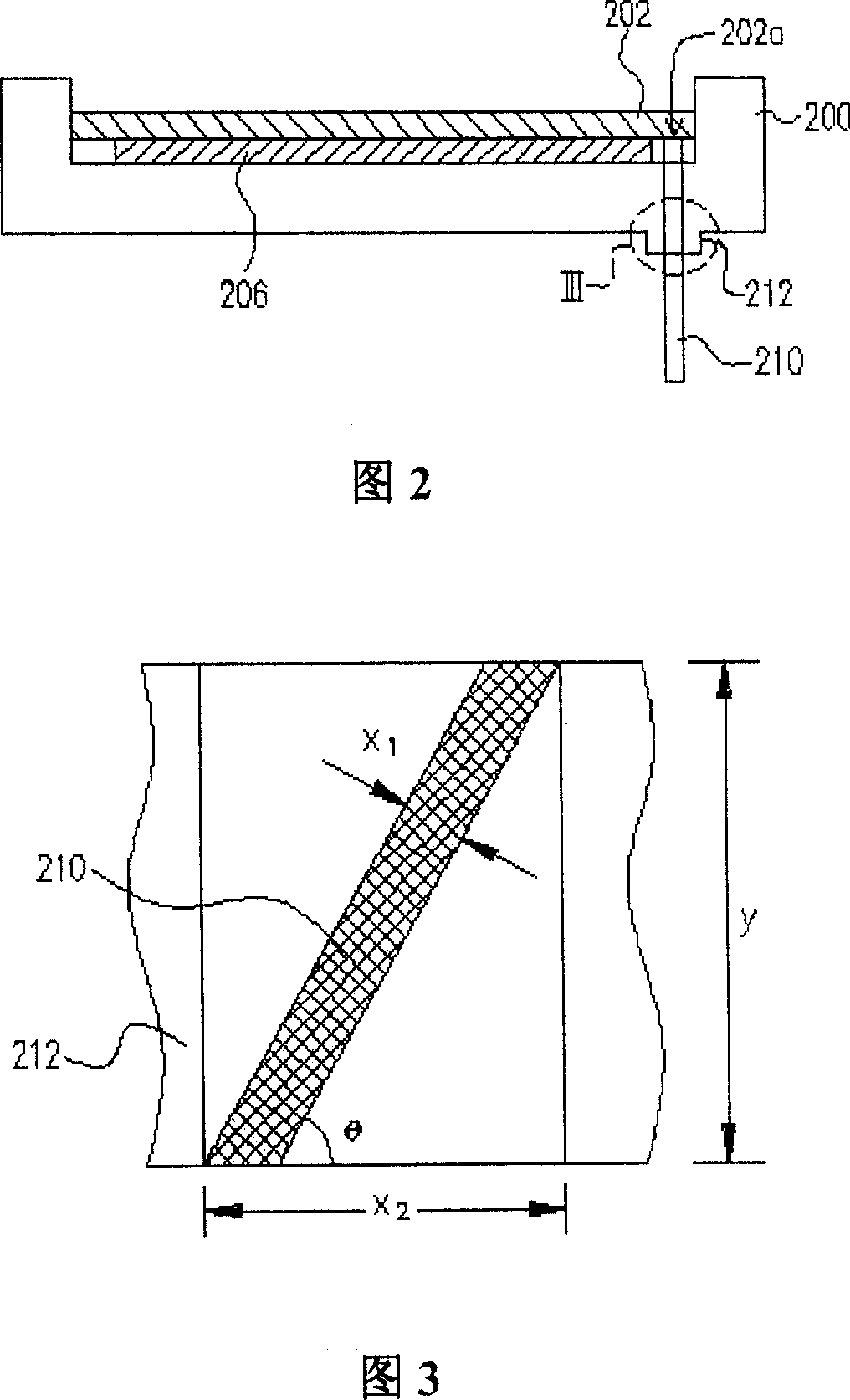

[0027] The present invention can be applied to any deposition chamber used in the deposition process. As shown in FIG. 2 , the device is used to deposit a thin film on a wafer while forming a mark for positioning.

[0028] FIG. 2 is a schematic side view of the component structure of a deposition chamber according to a preferred embodiment of the present invention. Please refer to FIG. 2, the parts of the deposition chamber include a shell (shield) 200, a pressure ring (clamp) 202, a screw (screw) 210 and an insulating part (isolator) 212, wherein the shell 200 is, for example, a wafer seat, The material of the screw 210 is a conductive material such as brass; and the material of the insulating part 212 is ceramic material, and its shape can be circular. Although only one screw 210 is shown in this figure, actually the number of screws 210 can be increased as needed, so the number of screws 210 is not limited to one. In addition, the insulating part 212 is integrally formed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com