Optical film thickness monitoring system

A technology of optical film thickness and monitoring system, applied in optics, optical components, optical devices, etc., can solve the problem of inability to eliminate noise, and achieve the effect of flexible and convenient use, elimination of influence, high reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

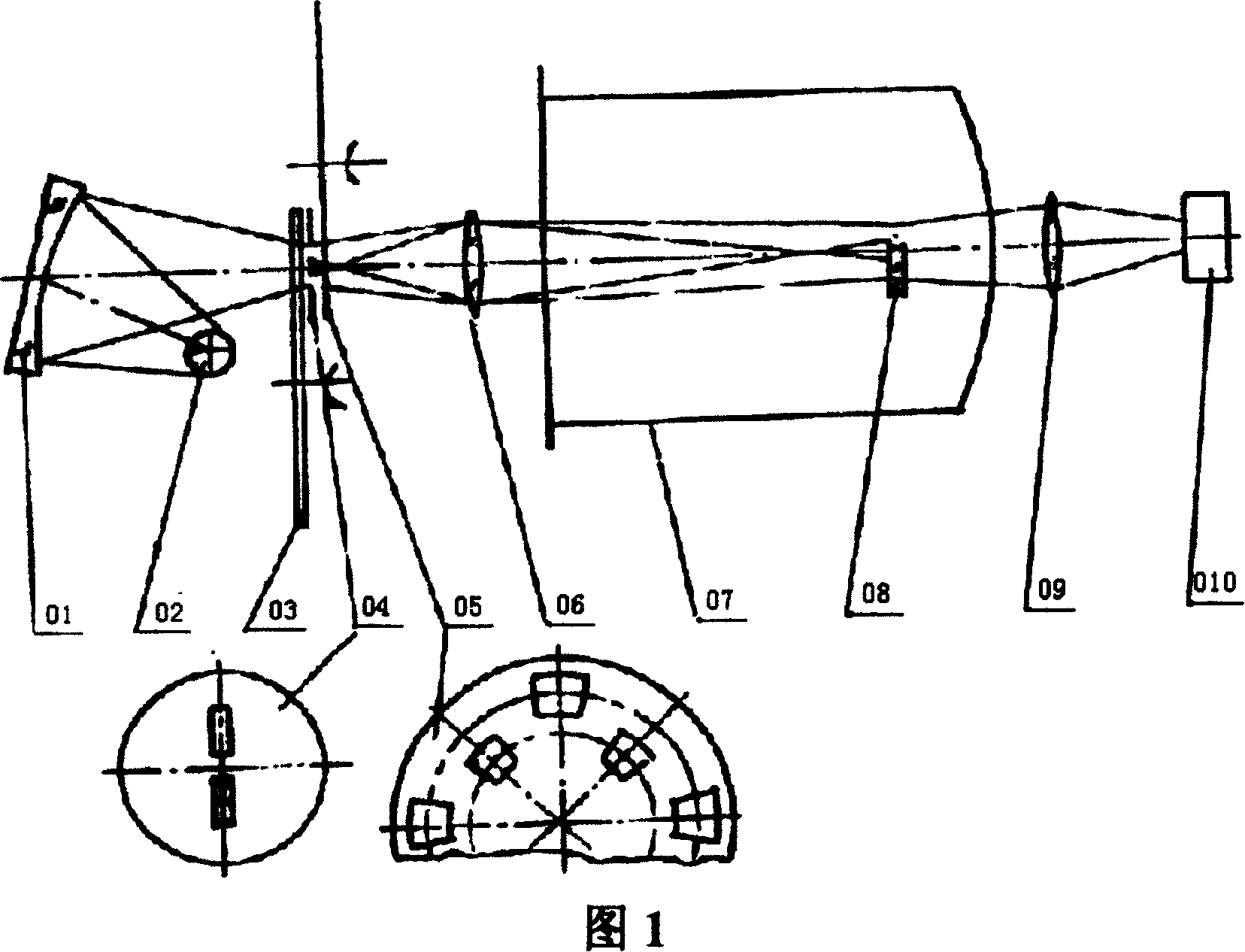

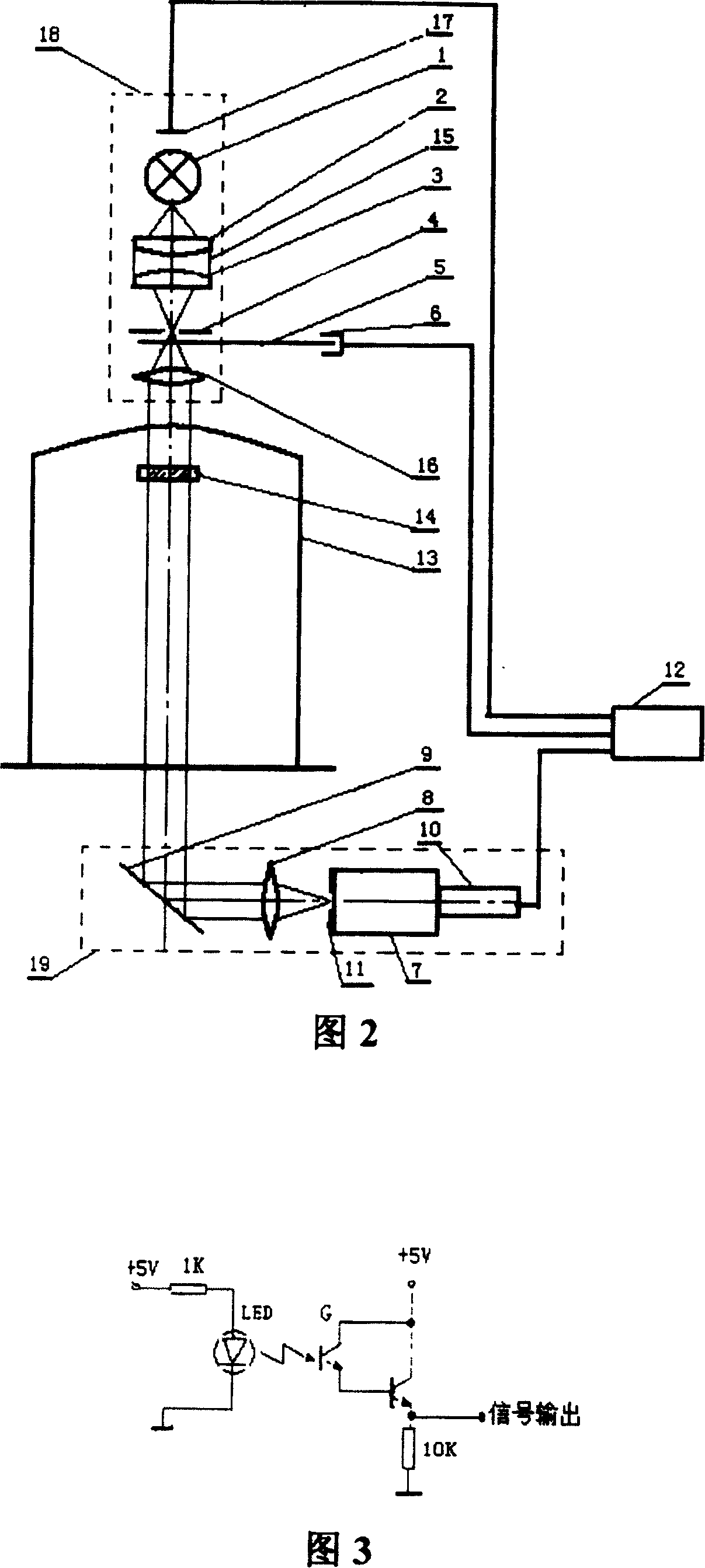

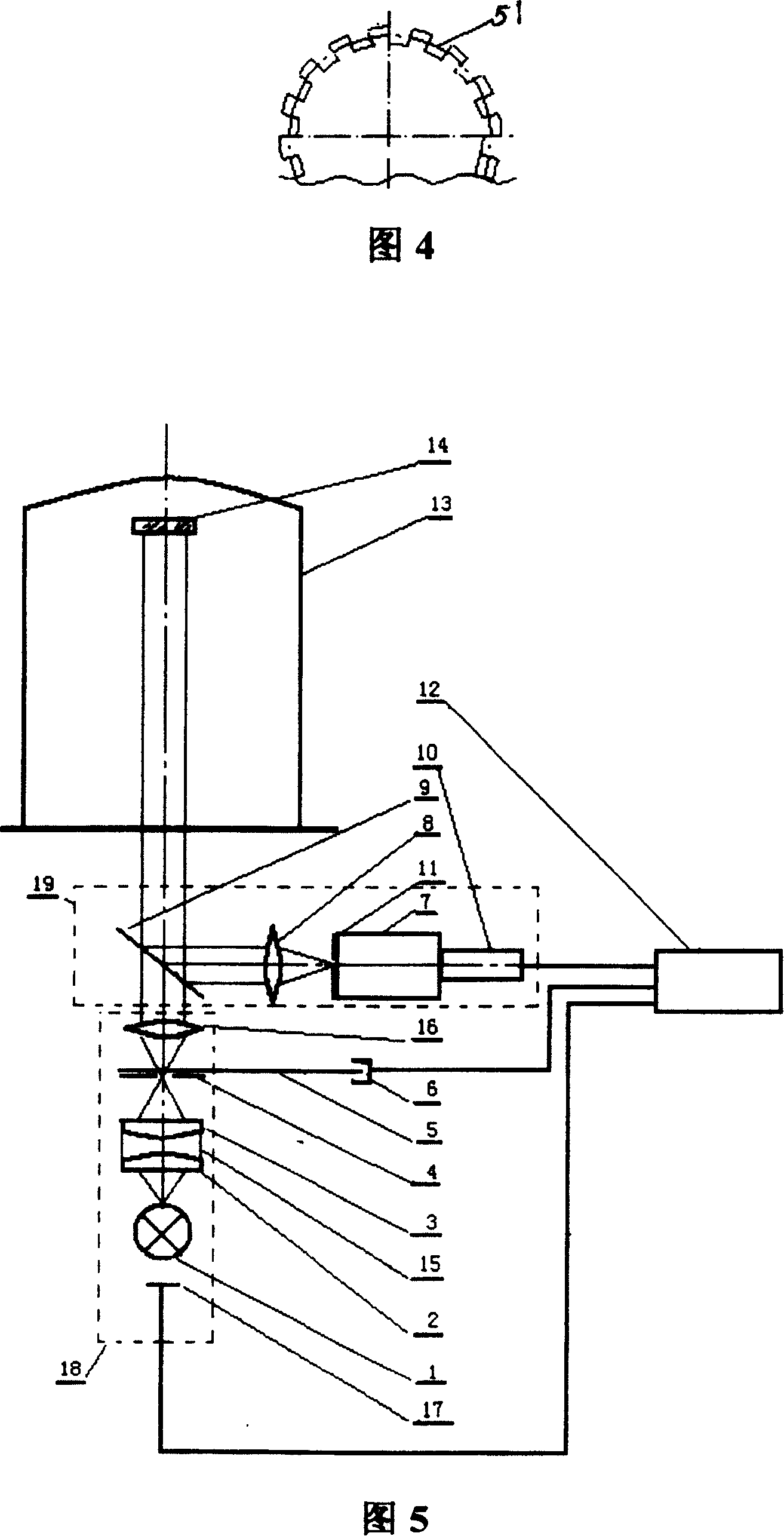

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0026] Please refer to FIG. 2 first. FIG. 2 is a schematic structural diagram of a transmissive optical film thickness monitoring system according to Embodiment 1 of the present invention. Four parts of system 19 and lock-in amplifier 12:

[0027] Described light source emission system 18 is assembled into one by the light source 1 with photocell 17 and the condenser lens 15 that is arranged successively along the advancing direction of the light beam that this light source 1 sends, diaphragm 4, single-row hole reticle 5 and collimator mirror 16, The aperture hole of the aperture 4 is placed at the focal point of the condenser 15, and the single-row aperture modulation disc 5 is provided with an optical switch 6, and the modulation aperture 51 on the periphery of the single-row aperture modulation disc 5 is close to the aperture 4 and located on the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com