Support free construction method for super large diameter circular deep foundation ditch

A technology with super-large diameter and construction method, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems of inconvenient construction, high project cost, waste of resources, etc., and achieve convenient excavation of soil, fast project progress, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

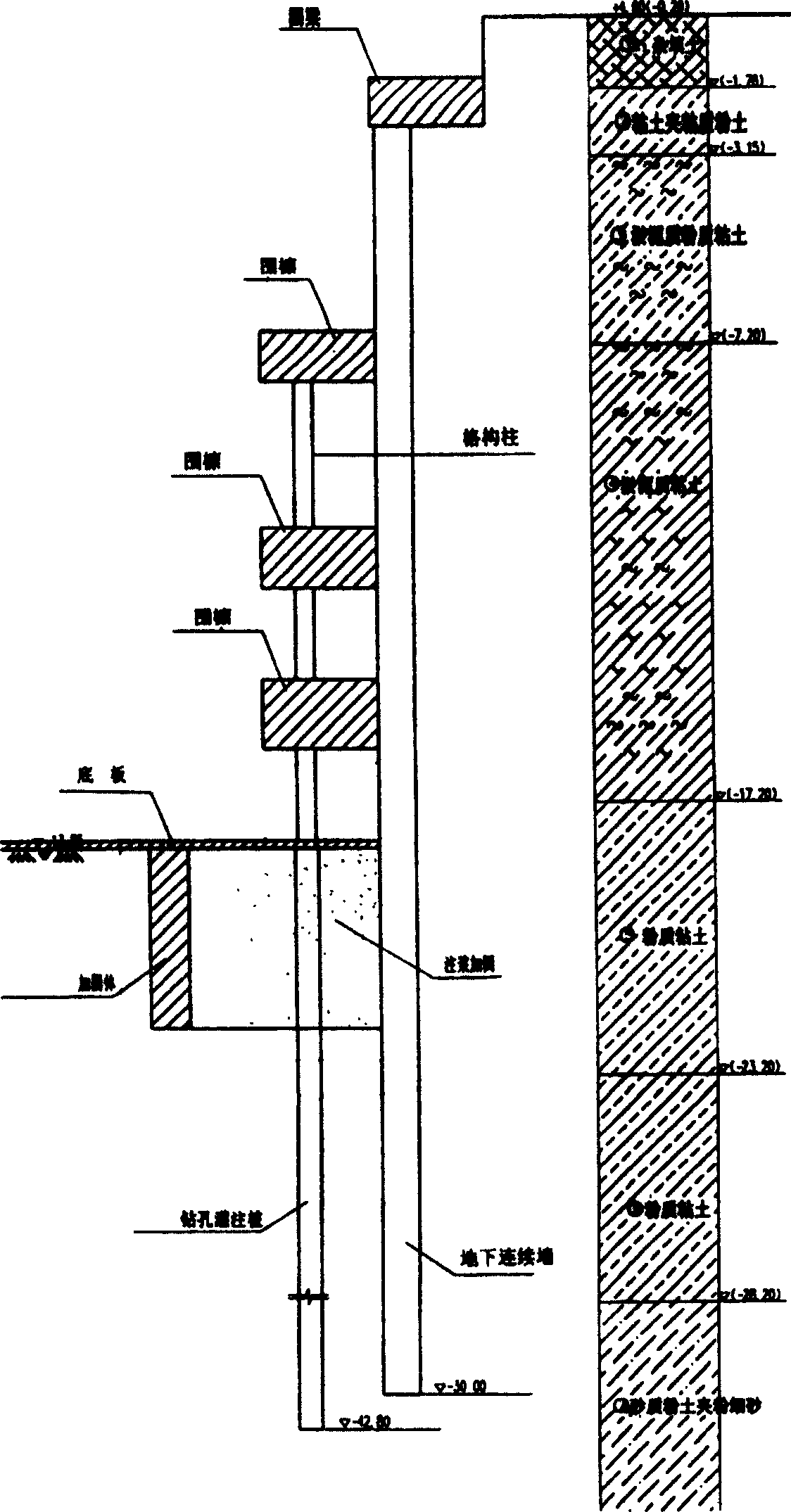

[0029] Taking the foundation pit in the tower area of Shanghai World Financial Center as an example, the excavation diameter of the foundation pit is within 100m, and the depth of the pit is about -13m. The specific steps of the construction method are as follows:

[0030] (1), build the underground diaphragm wall

[0031] ①. The thickness of the underground diaphragm wall is 1.0m, and the height of the underground diaphragm wall is 34.2m. Each segment of 2.0m is a broken line segment, and three broken line segments form a groove segment. According to the circumference of the foundation pit, determine the number of groove segments of the underground diaphragm wall for 52.

[0032] ②. Excavate the trough section with a trough forming machine until the wall bottom elevation is -30.0m (the ground elevation is +4.2m). During the excavation process, the grab should enter and exit the groove slowly and steadily, and the deviation should be corrected in time according to the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com