Disperse dye mixtures

A technology for dye mixtures and disperse dyes, applied in the direction of anthracene dyes, organic dyes, quinolinophthalone dyes, etc., which can solve the problems of insufficient over-reliance, poor level dyeing or migration properties, and insufficient overcoming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

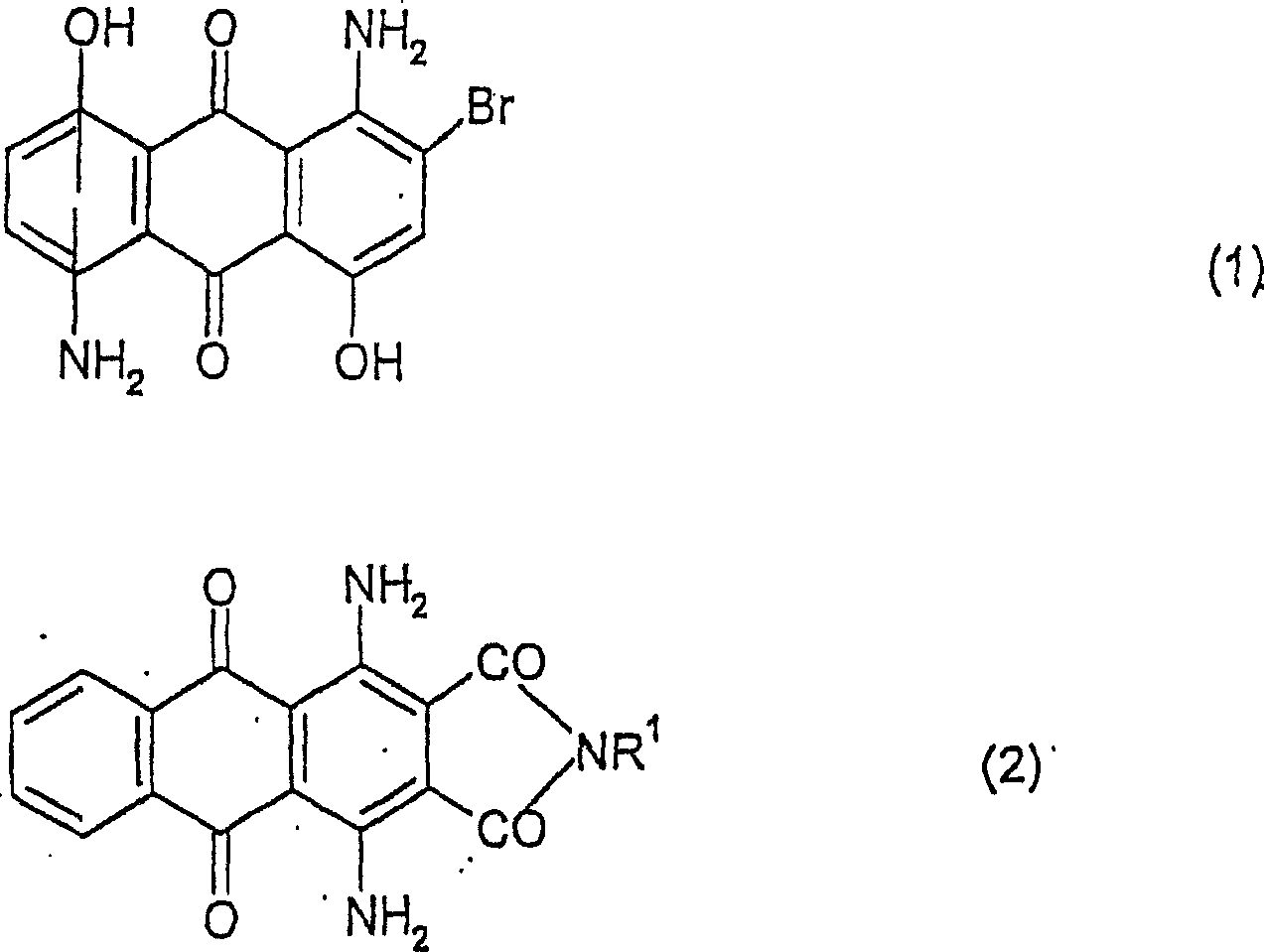

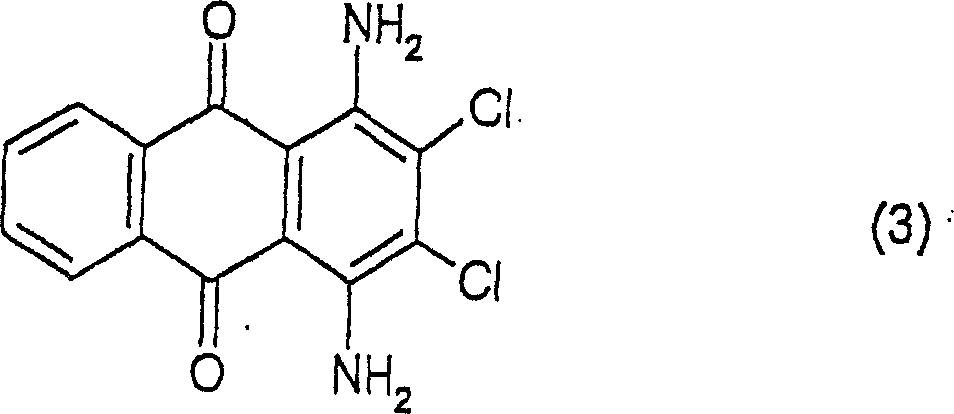

[0053] A blue dye mixture comprising 16.4 parts of the dye of formula (1), 5.7 parts of the dye of formula (3) and 10.6 parts of the dye of formula (2-1) was prepared by mixing the three dyes together and then mixing them in 40 % in the form of an aqueous slurry is ground with 20 parts of a high temperature stable dispersant until the dye particle size (average diameter) is 0.1-5 microns.

[0054]

[0055]

[0056] The dispersion was standardized to 32.7% mixture and 67.3% dispersant in solid form by adding 47.3 parts of heat stable dispersant and drying in a spray dryer to granule or powder form.

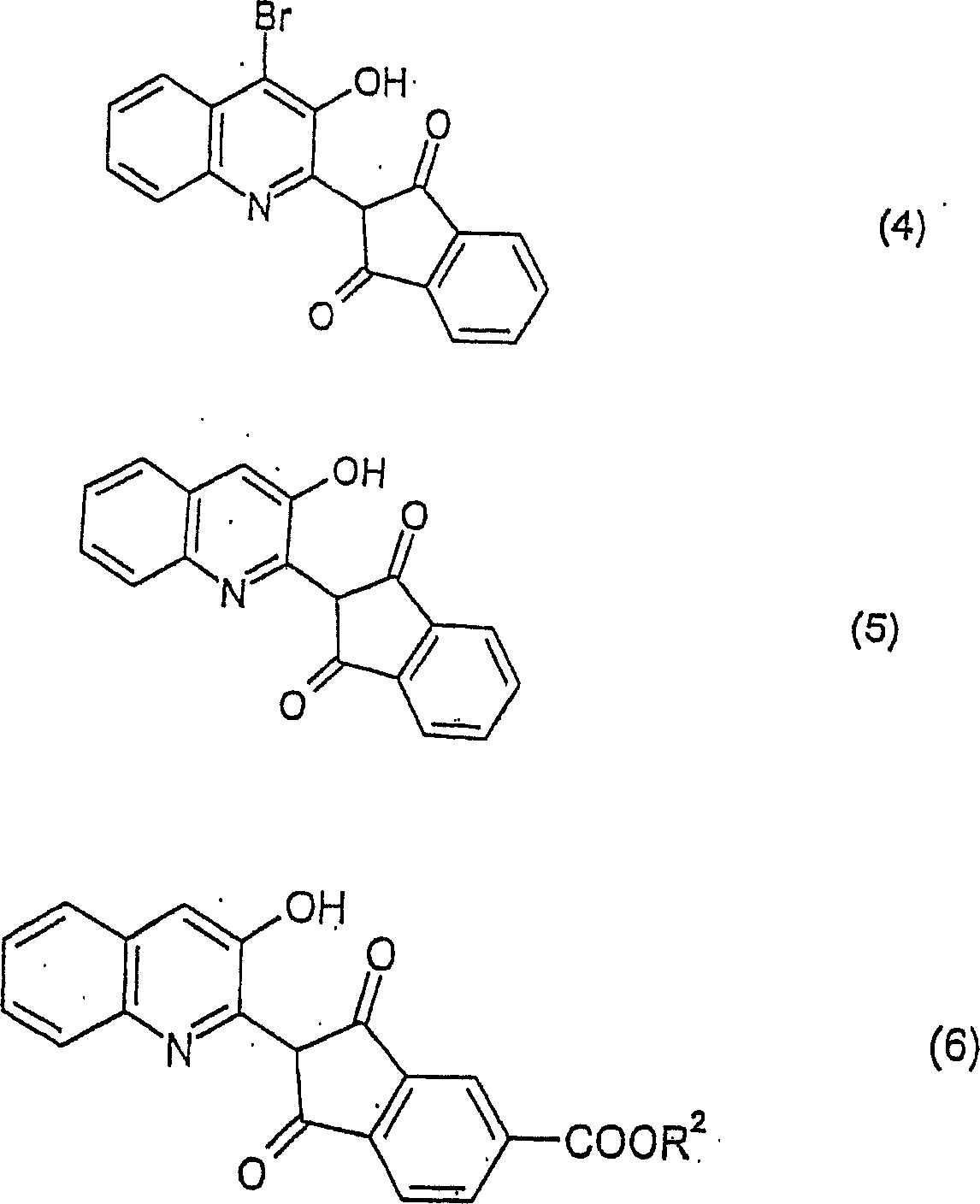

[0057] A yellow dye mixture comprising 5.9 parts of the dye of formula (4), 4.4 parts of the dye of formula (5) and 2.6 parts of the dye of formula (6-1) was prepared by mixing the three dyes together and then mixing them at 40% The form of an aqueous slurry is ground with 20 parts of a high temperature stable dispersant until the dye particle size (average diameter) is 0.1-5...

Embodiment 2

[0067] The preparation, dyeing and evaluation of the dye mixture were carried out in the same manner as in Example 1 except that the recipe was changed to the following:

[0068] The blue dye mixture comprises 18.2 parts of formula (1) dyes, 5.1 parts of formula (3) dyes and 8.0 parts of formula (2-1) dyes;

[0069] The yellow dye mixture comprises 5.9 parts of the dye of formula (4), 5.0 parts of the dye of formula (5) and 2.0 parts of the dye of formula (6-1); and

[0070] The red dye mixture comprises 9.1 parts of the dye of formula (7), 8.45 parts of the dye of formula (8) and 9.0 parts of the dye of formula (9). The results are given in Table 1.

Embodiment 3

[0072] The preparation, dyeing and evaluation of the dye mixture were carried out in the same manner as in Example 1 except that the recipe was changed to the following:

[0073] The blue dye mixture comprises 13.0 parts of the dye of formula (1), 6.5 parts of the dye of formula (2-1), 8.4 parts of the dye of formula (3) and 6.5 parts of the dye of formula (2-2):

[0074]

[0075] The yellow dye mixture comprises 4.6 parts of the dye of formula (4), 5.7 parts of the dye of formula (5) and 2.6 parts of the dye of formula (6-1); and

[0076] The red dye mixture comprises 7.0 parts of the dye of formula (7), 14.0 parts of the dye of formula (8) and 7.0 parts of the dye of formula (9). The results are given in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com