Refrigeration compressor

A technology for refrigeration compressors and compressors, applied in mechanical equipment, machines/engines, rotary piston machines, etc., can solve problems such as inconvenient movement, large compressor motor loss, and low compressor efficiency, and achieve convenient processing and assembly, The effect of increasing the cooling speed and reducing the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

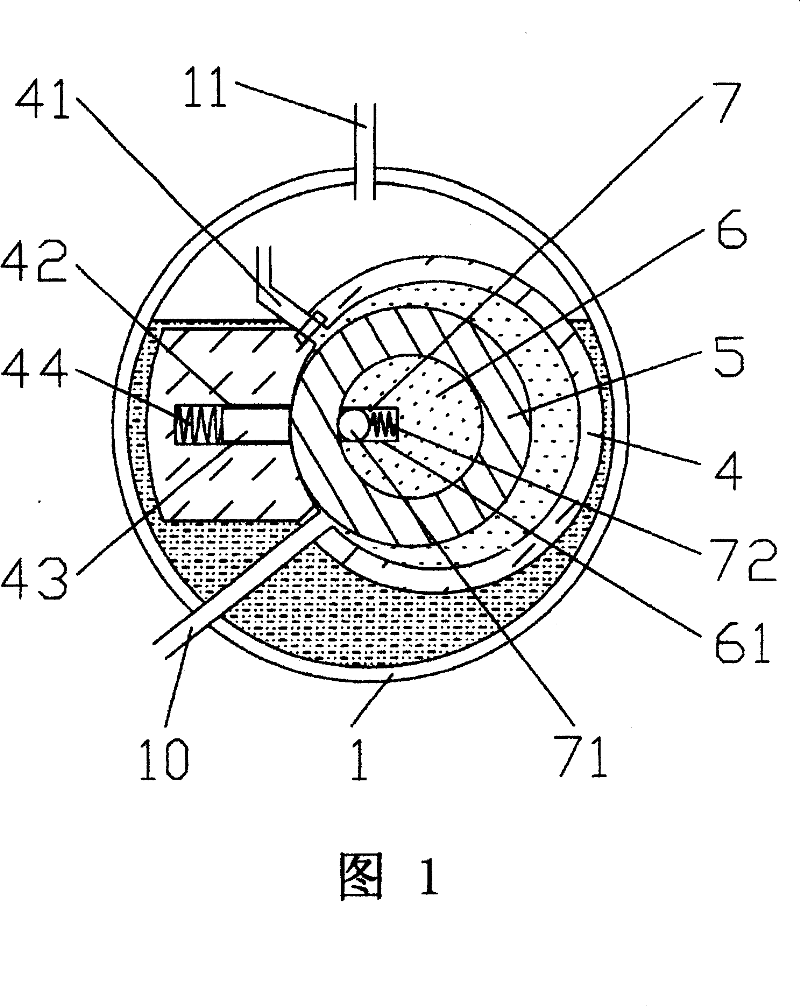

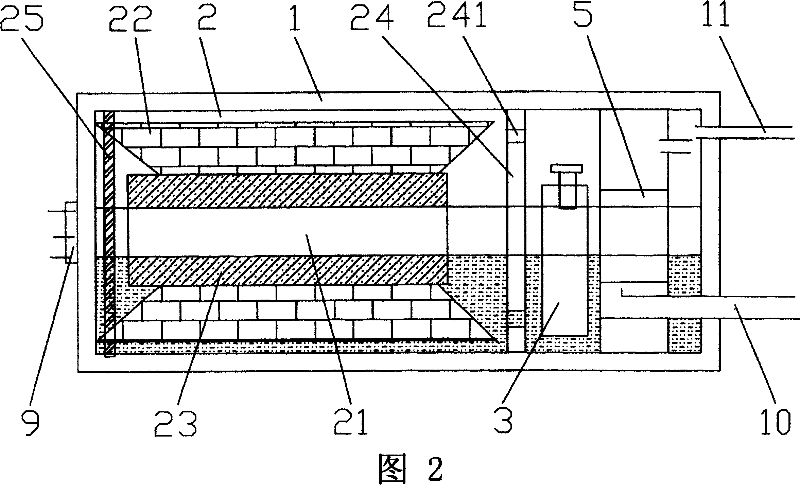

[0025] See accompanying drawings 1 to 3, the compressor of the present invention mainly includes: housing 1, motor 2, balance weight 3, cylinder 4, piston 5 and eccentric shaft 6; motor 2, balance weight 3 and cylinder 4 are located in housing 1 ; Motor 2 is made of rotating shaft 21, stator 22, rotor 23, front end cover 24, rear end cover 25; ) is connected with the eccentric shaft 6. Between the front end cover 24 and the eccentric connection mechanism, there is a balance weight 3 fixed on the rotating shaft 21 by screws; its direction is just opposite to that of the eccentric shaft 6, so that the eccentric force of the compressor is offset and kept in balance; and, at the front end The cover 24 is provided with a through hole 241, and when the balance weight 3 rotates under the action of the rotating shaft 21, the lubricating oil in the compressor can be splashed into mist and stay in various positions that need to be lubricated, such as the motor 2. The motor 2 is a low-v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com