Sliding medium material for building berth serial shipbuilding

A medium material, slip technology, applied in slipway, ship, transportation and packaging, etc., can solve the problems of uncontrolled movement and fast moving speed of half ship, achieve no material loss, avoid slipway transformation, and increase tonnage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment further illustrate the present invention.

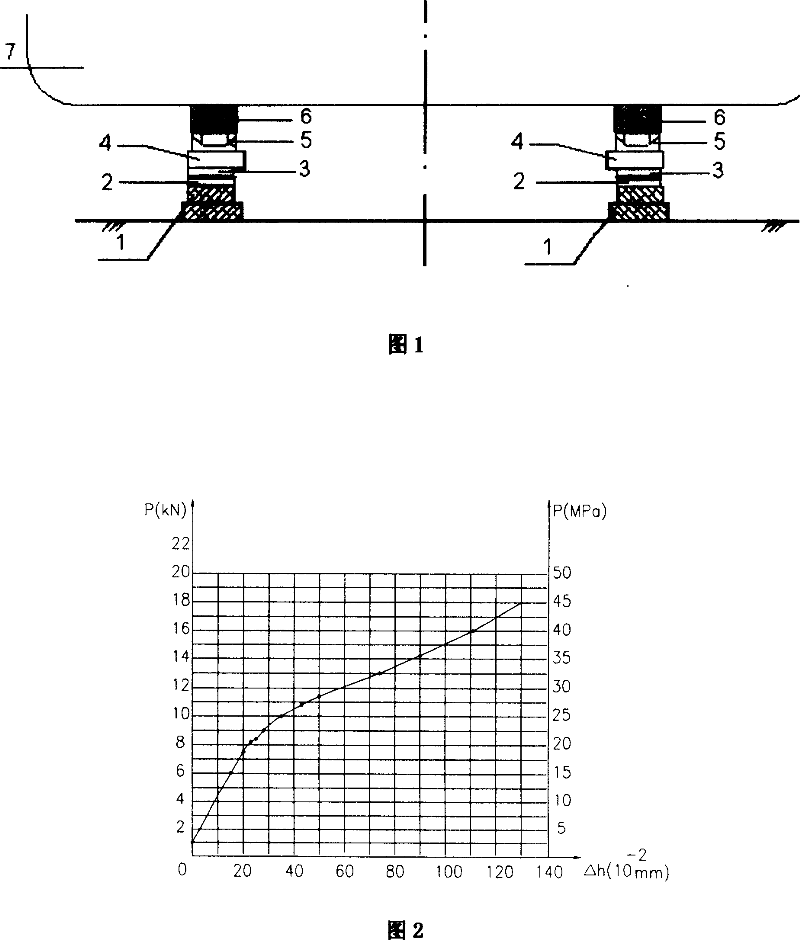

[0029] A sliding medium material for slipway series shipbuilding, including a moving layer, a fixed layer and a lubricant, and the sliding layer 3 is an ultra-high molecular weight polyethylene plate (UHMW-PE). The ultra-high molecular weight polyethylene plate is provided with oil grooves and oil pits. The ultra-high molecular weight polyethylene board (UHMW-PE) is tightly fixed on the bottom of the special iron slide 4 with bolts, and together they are used as the transport carrier for the half boat 7 to move down. The polyethylene board is equipped with oil grooves and oil pits to improve the lubrication performance . Lubricating oil is made by mixing machine oil and tallow in a ratio of about 1:8, and the ratio varies in different seasons to adapt to different climatic conditions. Lubricant is respectively applied to the surface of the anti-slip steel plate 2 and the ultra-high molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com