Developing device using toner and carrier mixture

A developing device and toner technology, which are applied in the direction of developer, electric recording process applying charge pattern, equipment of electric recording process applying electric charge pattern, etc., can solve problems such as inability to accommodate developer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

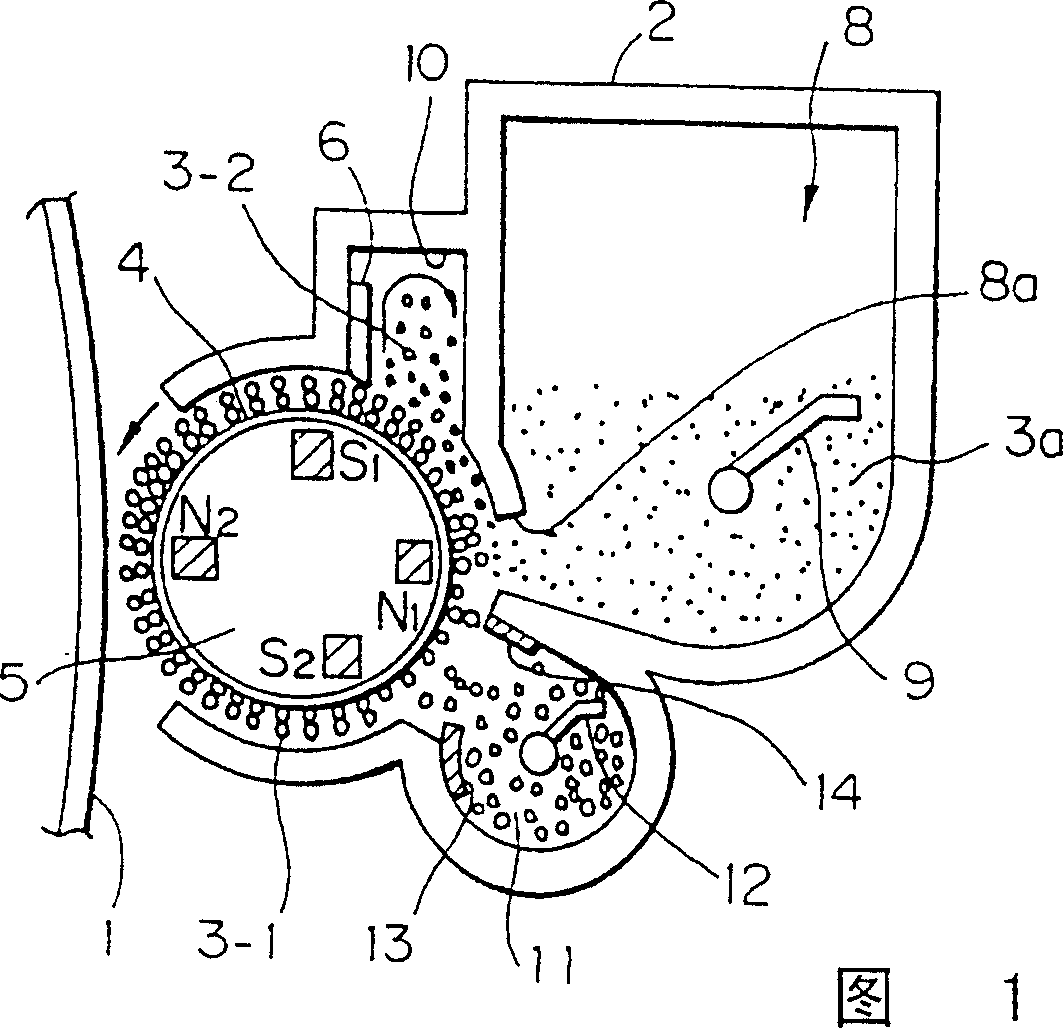

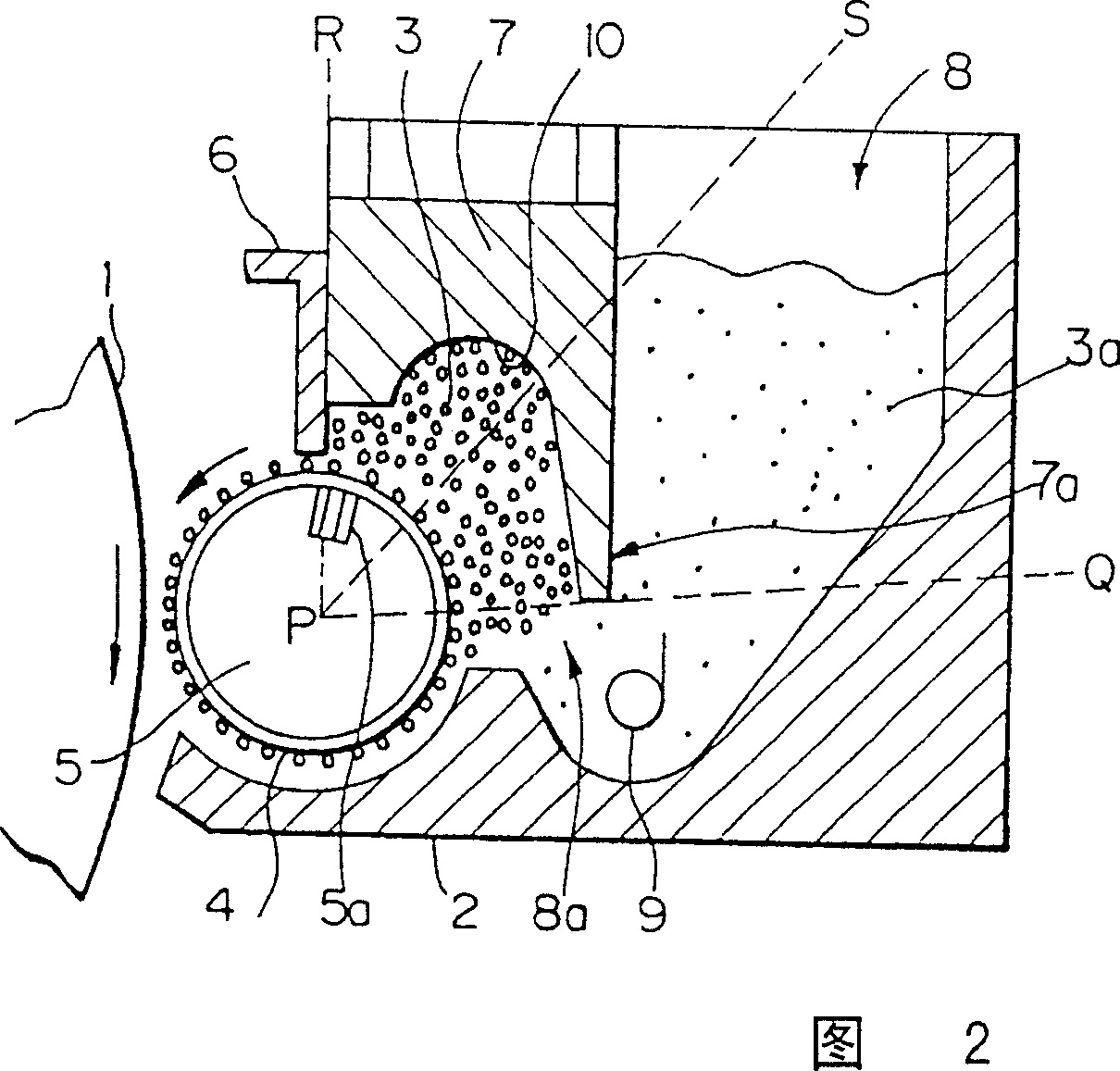

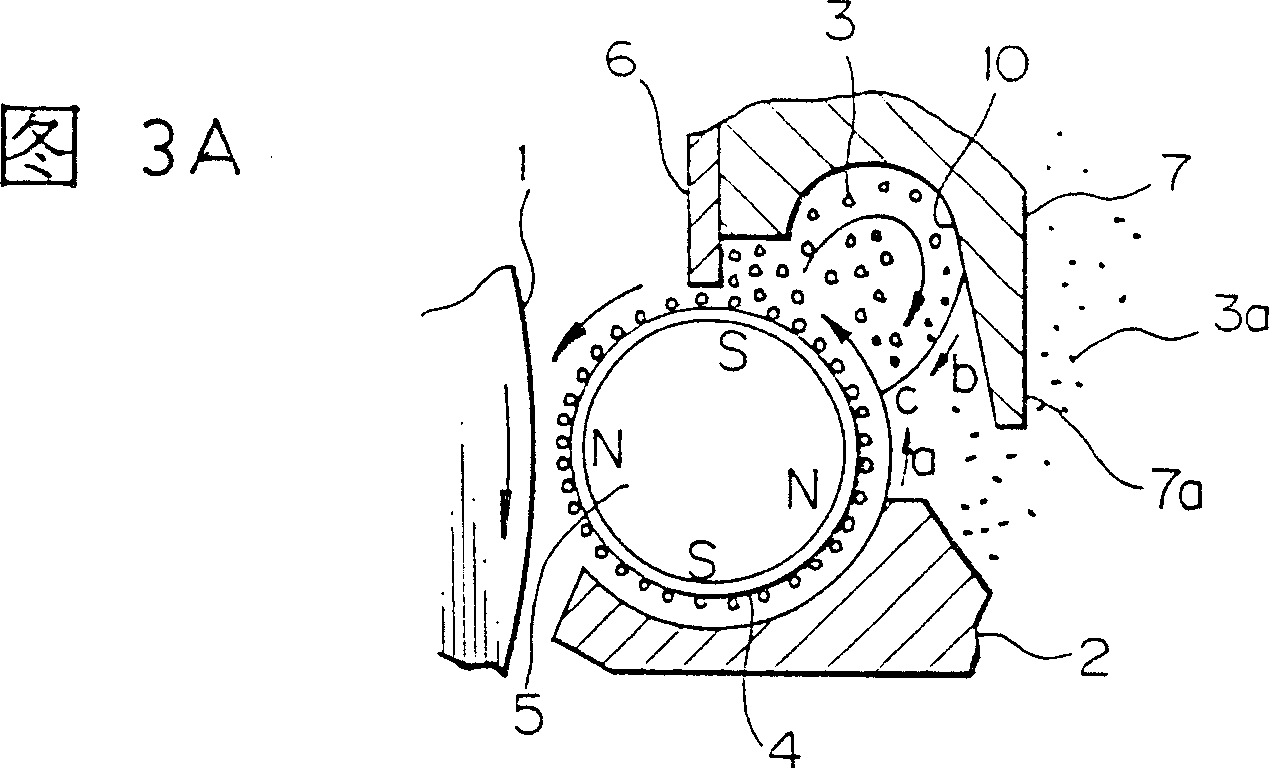

[0061] Referring to FIG. 1 , the developing device of the present invention includes a casing 2 . The case 2 may be located on one side of the image carrier 1 as a photoconductive drum, for example. The box 2 has an opening facing the carrier 1 . A developing sleeve or developer carrier 4 is deposited in the above-mentioned case 2 and partially exposed to the outside through the above-mentioned opening. A developer including magnetic toner and magnetic carrier remains on the surface of the above-mentioned sleeve 4 . Fixed in the sleeve 4 is a cylindrical magnet element or magnetic field generator 5 comprising a set of fixed magnets. A scraper or regulator 6 regulates the amount of developer deposited on the aforementioned sleeve 4 .

[0062]The inner side of the box body 2 is provided with a sleeve cavity for accommodating the above-mentioned sleeve 4, a developer storage cavity 10 for storing the developer scraped off by the scraper 6, a developer storage cavity 11, and a ...

example 1

[0097] First, use a hot roller at 120°C to melt and knead the mixture with the ingredients listed in Table 1 below, cool it to solidify, use a jet mill to pulverize the solidified body, and then sieve it to form an average particle size The toner particle a is 16 μm. The toner at 8.0 x 10 4 The saturation magnetization in a magnetic field of A / m is 60A.m 2 / kg.

[0098] Table 1

[0099] Styrene-acryloyl resin (Himer75 product available from Sanyo Kagaku company) 100 parts by weight

[0100] Carbon black (#44 product available from Mitsubishi kasei company) 5 parts by weight

[0101] Nigrosine dye (Nige color base EX product available from Orient company) 2 parts by weight

[0102] Tiny magnet particles (EPT-1000 product available from Toda kogyo company) 60 parts by weight

example 2

[0104] The procedure was the same as that of Toner Example 1 except that the mixture listed in Table 2 below was used, whereby Magnetic Toner b was prepared. The toner at 8.0 x 10 4 The saturation magnetization in a magnetic field of A / m is 20A.m 2 / kg.

[0105] Table 2

[0106] Styrene-acryloyl resin (Himer75 product) 100 parts by weight

[0107] Carbon black (#44 product) 5 parts by weight

[0108] Nigrosine dye (Nige color base EX product) 2 parts by weight

[0109] Tiny magnet particles (EPT-1000 product) 100 parts by weight

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Weight average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com