Deflection correcting device for paper machine

A technology of a deviation correction device and a paper machine, which is applied in the field of deviation correction devices, can solve the problems of poor follow-up and stability of the system, affecting the deviation correction function, pressure regulation, and sluggish exhaust reaction, and achieves compact structure, overcoming deviation correction, and easy follow-up. The effect of mobility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

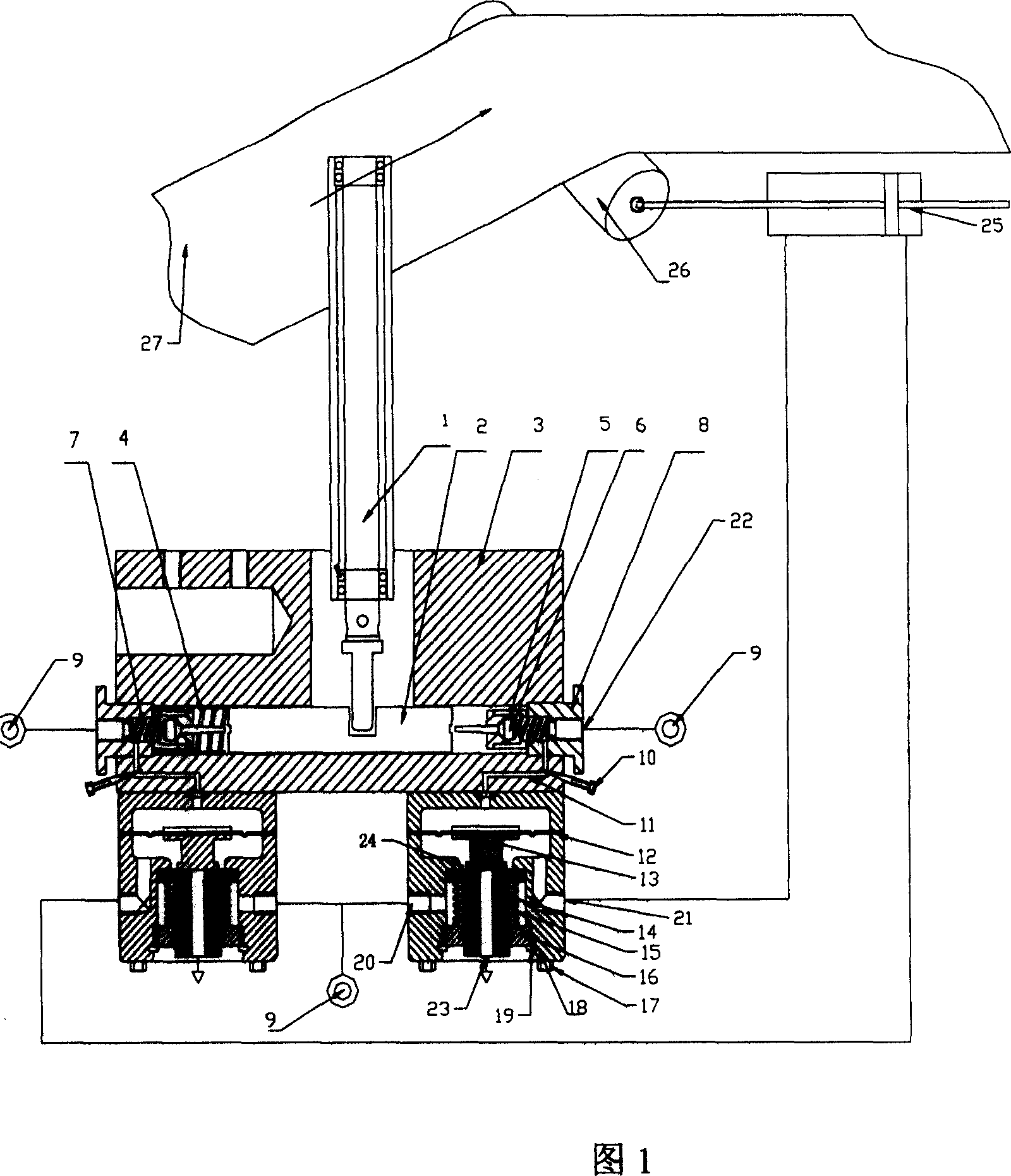

[0009] As shown in Figure 1, the signal control valve is composed of a swing rod 1, a slider 2, a valve body 3, a centering spring 4, a valve core seat 5, a conical valve core 6, a return spring 7 and a valve seat 8. The middle of the pendulum 1 is connected with the valve body 3 by a pin shaft, one end is connected to the slider 2 located in the valve body 3, and the other end is close to the edge of the net blanket. When the net blanket deviates, its edge can push the pendulum 1 swing. The swing of the fork 1 can make the slide block 2 move left and right in the valve body 3 . The valve body 3 on the left and right sides of the slider 2 is respectively equipped with a valve core seat 5, a conical valve core 6 and a valve seat 8. The valve core seat 5 is placed between the slider 2 and the valve seat 8, and is connected with the screw thread The valve seat 8 is connected, the conical valve core 6 is placed in the valve core seat 5, and its conical end passes through the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com