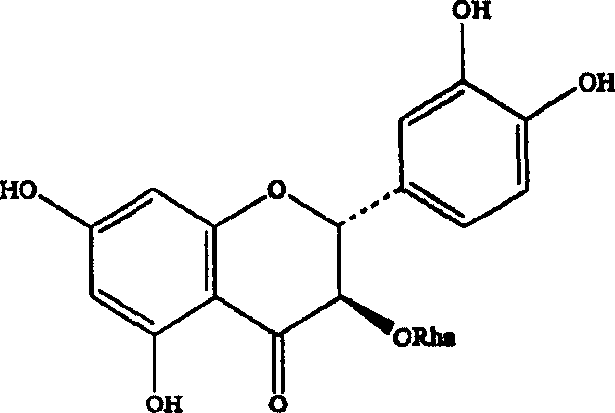

Preparation method of astilbin

An astilbin, weight technology is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve problems such as waste of resources, and achieve the effects of low cost, high purity and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Pulverize the medicinal material of Huangqi leaf into coarse powder, extract by percolation with 95% ethanol 10 times the weight of the material and 80% ethanol 15 times the weight, and collect the percolation liquid. 95% ethanol extract is degreased with petroleum ether, concentrated to extract, added ethanol to make the solution concentration 20% ethanol aqueous solution, after dissolving, place to precipitate, separate the precipitate, combine mother liquor with 80% ethanol extract, concentrate to each 3 grams of crude drug in milliliters is extracted with ethyl acetate equivalent to 2 times the amount of crude drug, the ethyl acetate extract is concentrated to extractum, and aqueous ethanol solution is added to make the solution concentration 20% ethanol aqueous solution, which is left to precipitate after dissolving. Separate the precipitate, combine the precipitates obtained from the two alcohol precipitations, pass through the polyamide column after dis...

Embodiment 2

[0021] Embodiment 2: Pulverize the medicinal material of Huangqi leaf into a coarse powder, use 15 times of the weight of the material to extract 90% ethanol and 10 times the amount of 60% ethanol by percolation, collect 90% ethanol extract and 60% ethanol extract, and extract with 90% ethanol After the liquid is degreased with petroleum ether, the extract is concentrated to an extract, and ethanol is added to make the solution concentration 60% by weight of ethanol aqueous solution, dissolved, placed to precipitate, and the 60% ethanol extract is combined with the mother liquor after the aforementioned alcohol precipitation, and concentrated with Extract with ethyl acetate with 5% ethanol, concentrate the ethyl acetate extract to the extract, add ethanol to make the ethanol concentration 60%, leave it to precipitate after dissolving, combine the precipitates obtained from the two alcohol precipitations, dissolve in water and pass through LSA-10 Macroporous resin (produced by X...

Embodiment 3

[0022] Example 3: Pulverize the medicinal material of Huangqi leaf, extract by gradient percolation with 20 times the weight of the material 95% ethanol and 8 times the amount of 20% ethanol, collect 95% ethanol extract and 40% ethanol extract respectively, and use petroleum ether for the 95% ethanol extract After degreasing, concentrate the extract to the extract, dissolve it in water and place it to precipitate, combine and concentrate the 40% ethanol extract with the mother liquor after alcohol precipitation, then extract with ethyl acetate containing 20% ethanol, and concentrate the ethyl acetate part to the extract Finally, add ethanol to make the ethanol concentration 80%, put it aside after dissolving, combine the precipitates obtained by two alcohol precipitations, dissolve in water, pass through a polyamide column, and elute with 50% ethanol solution. After the eluent evaporates the solvent, 70% ethanol Astilbin monomer was obtained by recrystallization. After recrys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com