Method for preparing nanometer calcium carbonate granule

A nano calcium carbonate and particle technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of unstable operation, high energy consumption, uneven particle size, etc., and achieve high CO2 utilization rate, low energy consumption, and mixing speed. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

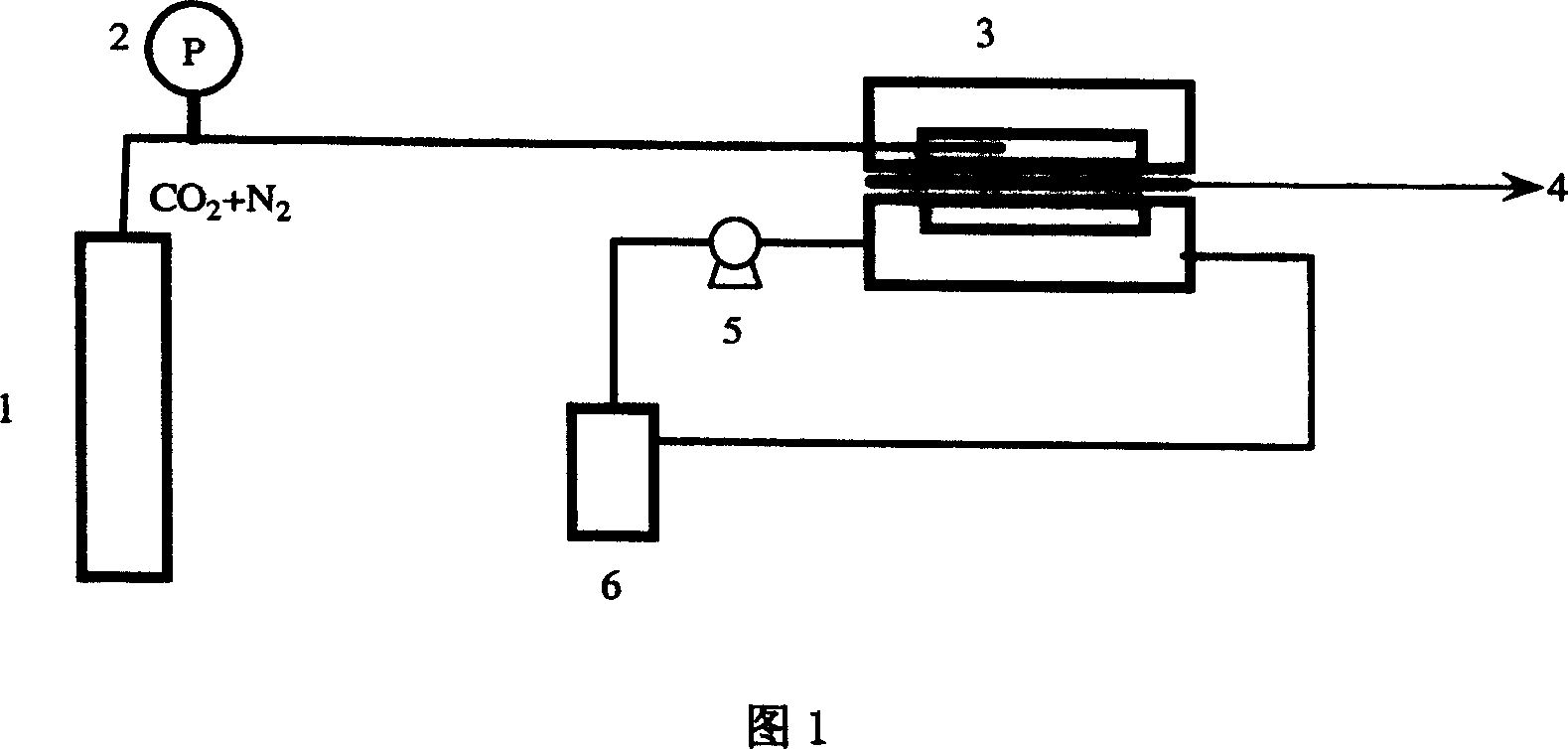

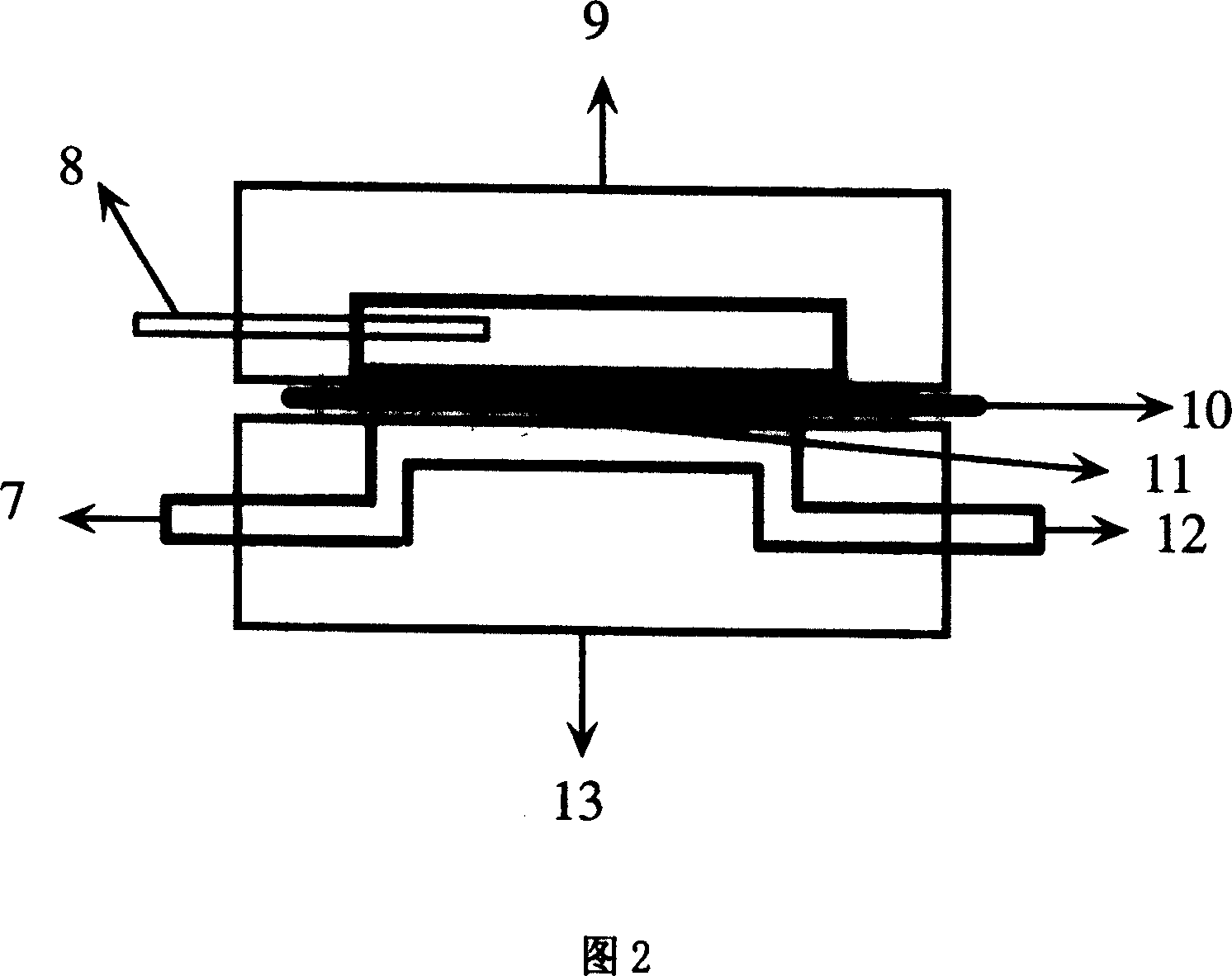

[0036] The dispersion medium is a nickel film with a pore size of 0.2 μm, and the effective film area is 12.5 mm 2 , CO 2 Mixed gas with nitrogen (CO 2 Volumetric concentration is 30%) enters reactor 4 with the flow rate of 50ml / min, Ca(OH) 2 The initial solid concentration in the suspension is 2g / 100ml water, the flow velocity of the suspension on the surface of the dispersion medium 4 is 0.3m / s, the residence time in the reactor is 0.3s, and the reaction temperature is 15°C. , transmission electron microscope photos show that the diameter of the generated nano-calcium carbonate particles is 20nm, the shape is cube, CO 2 The utilization rate is 83.7%.

Embodiment 2

[0038] The dispersion medium is a stainless steel membrane with a pore size of 5 μm, and the effective membrane area is 12.5mm 2 , CO 2 Mixed gas with nitrogen (CO 2 Volumetric concentration is 30%) enters reactor 4 with the flow rate of 50ml / min, Ca(OH) 2 The initial solid concentration in the suspension is 2g / 100ml of water, the flow velocity of the suspension on the surface of the dispersion medium 4 is 0.5m / s, the residence time in the reactor is 0.3s, and the reaction temperature is 15°C. , the transmission electron microscope photos show that the diameter of the generated nano-calcium carbonate particles is 33nm, the shape is a cube, CO 2 Utilization rate 81.2%

Embodiment 3

[0040] The dispersion medium is a stainless steel membrane with a pore size of 5 μm, and the effective membrane area is 12.5mm 2 , pure CO 2 Enter reactor 4 with a flow rate of 50ml / min, Ca(OH) 2 The initial solid concentration in the suspension is 2g / 100ml of water, the flow velocity of the suspension on the surface of the dispersion medium 4 is 0.5m / s, the residence time in the reactor is 0.3s, and the reaction temperature is 15°C. , the transmission electron microscope photos show that the diameter of the generated nano-calcium carbonate particles is 53nm, the shape is a cube, CO 2 The utilization rate is 80.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com