Portable braking force tester for car

A small car, braking force technology, used in vehicle testing, force/torque/work measuring instruments, braking safety systems, etc. problems, to achieve the effect of easy self-detection, easy operation, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

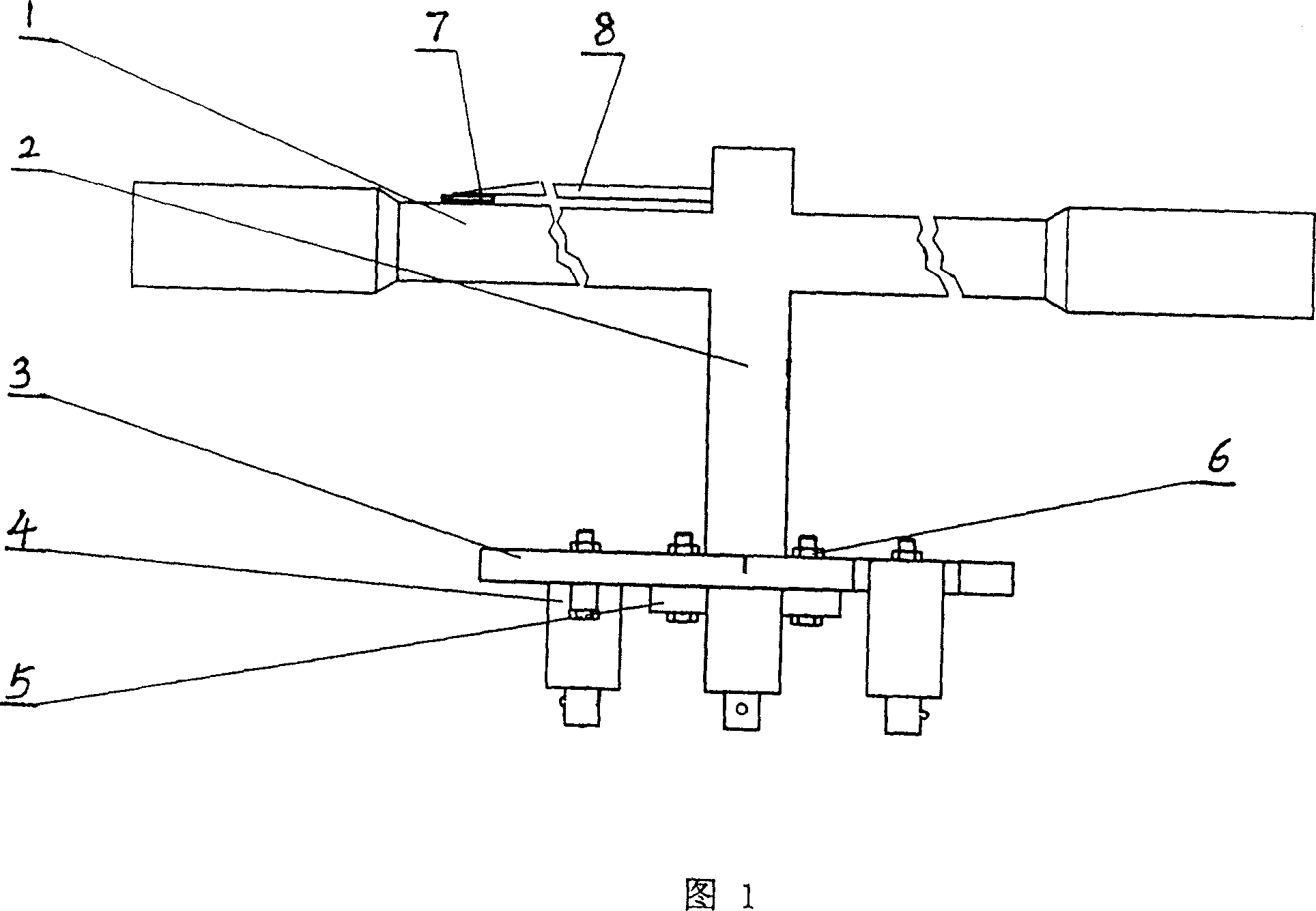

[0020] According to Figures 1 to 3 and the portable small car braking force tester of the present invention with the above structure, the two-way booster rod 1 and the rigid force transmission shaft 2 of this embodiment are integrally forged, and the center of the two-way booster rod 1 is vertically connected to the rigid force transmission shaft 2. The left end of two-way booster rod 1 fixes instrument panel 7; The right end of instrument pointer 8 is provided with screw thread, and instrument pointer 8 threads are tightly connected to the upper end of above-mentioned rigid power transmission shaft.

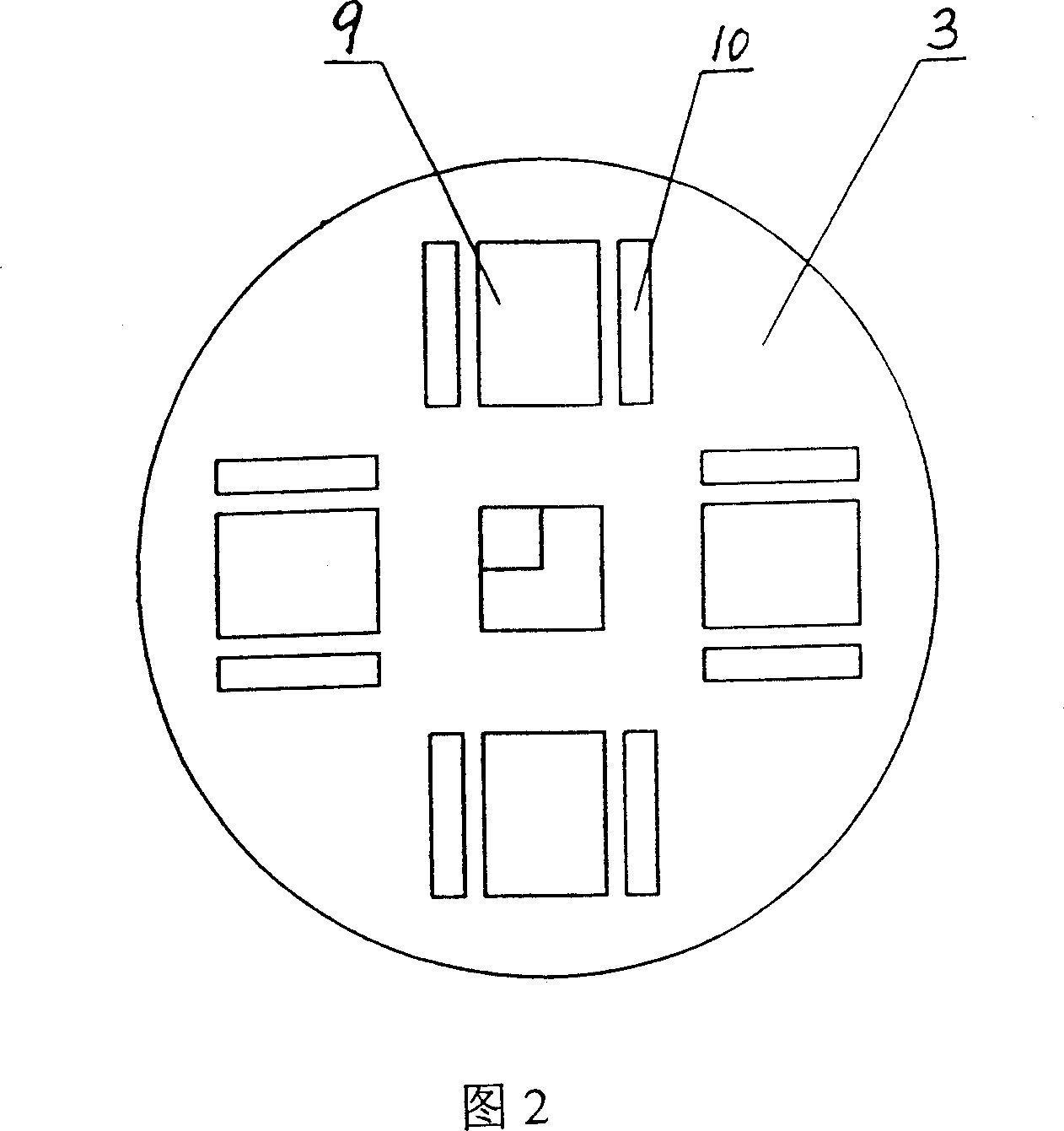

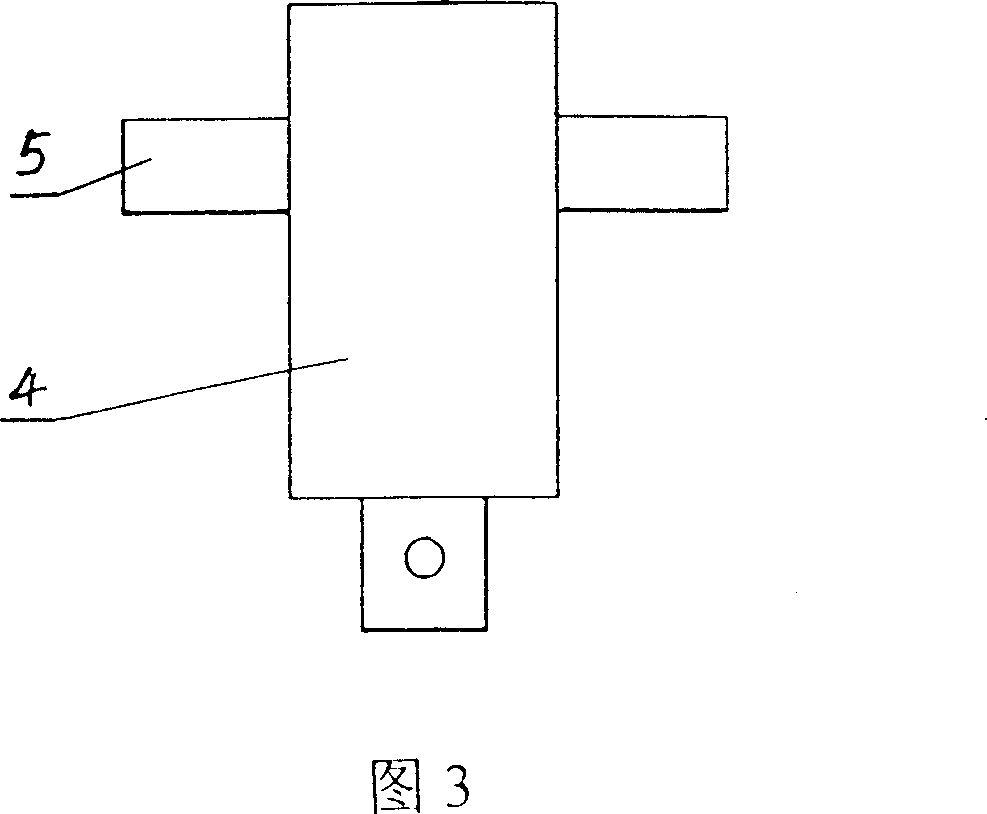

[0021] Referring to FIG. 2 , four wide grooves 9 and eight narrow grooves 10 are symmetrically distributed on the hub sleeve 3 . The eight narrow grooves 10 are arranged in pairs on both sides of each wide groove 14 . The bolt 6 passes through the narrow groove 10 and the ear hole of the lug 5 of the sliding sleeve 4 and is connected with the hub sleeve 3 , thereby realizing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com