Hydraulic unit for industrial trucks

一种液压装置、卡车的技术,应用在蓄能器的装置、流体压力致动装置、泵装置等方向,能够解决回流过滤器多单独零件等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

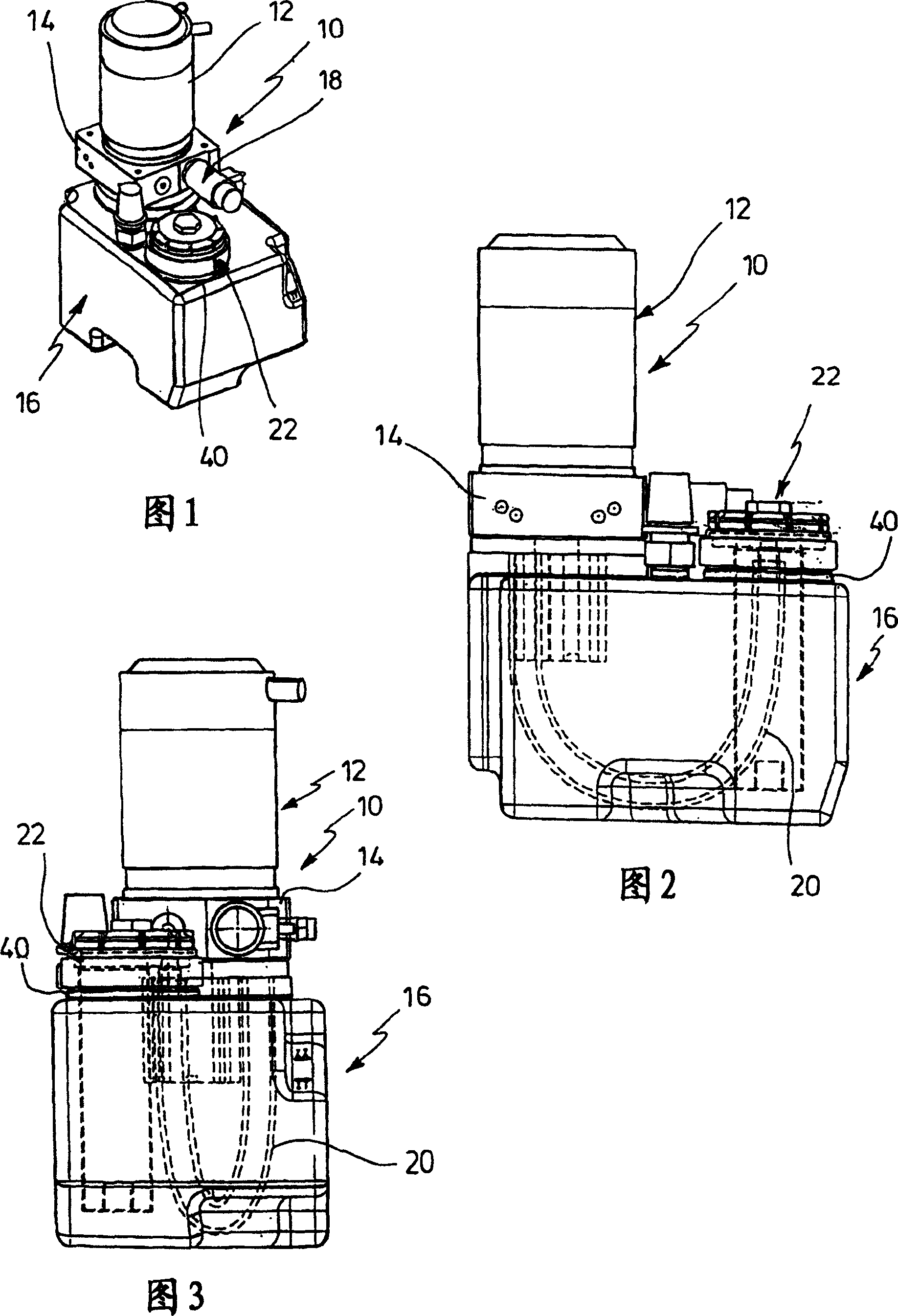

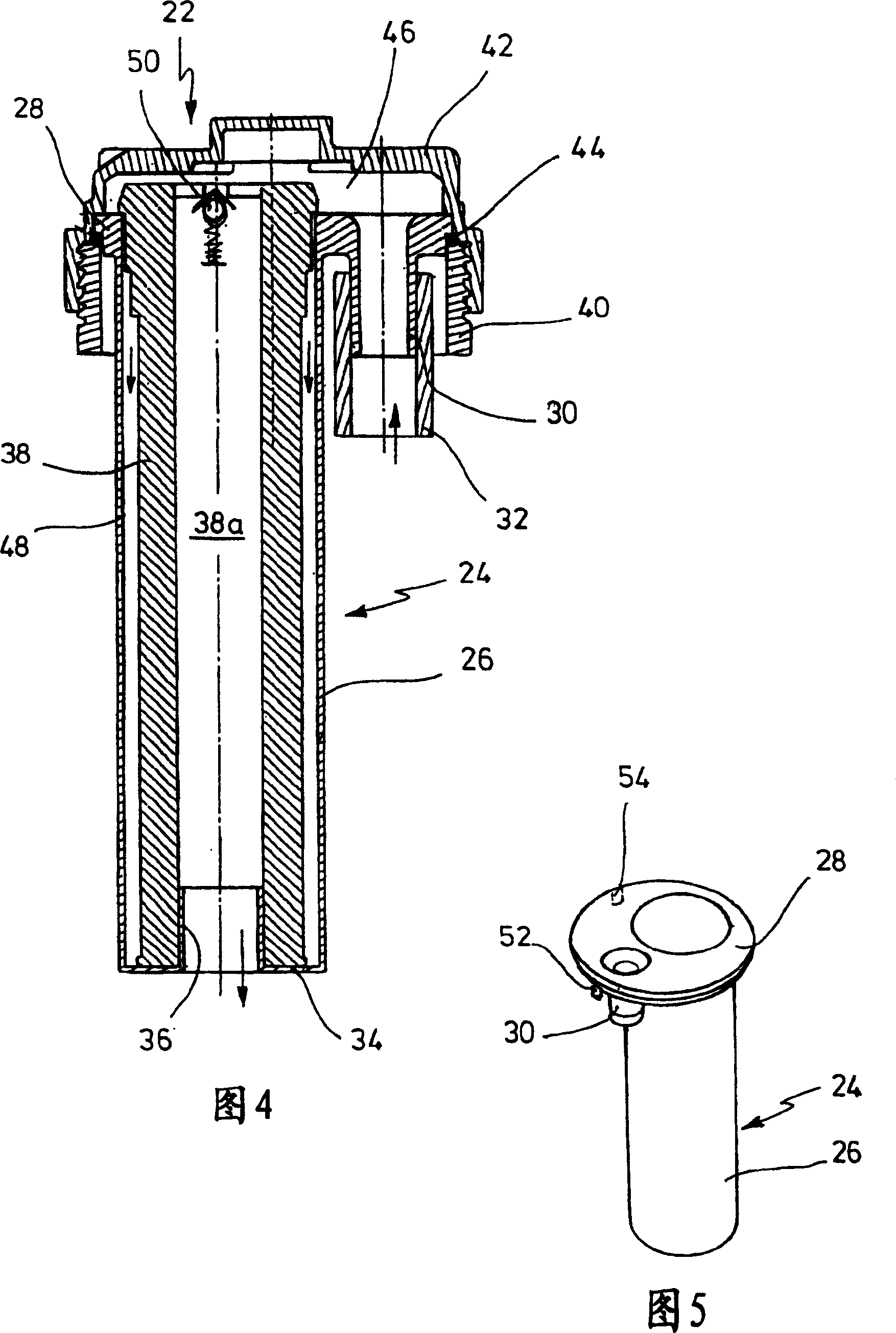

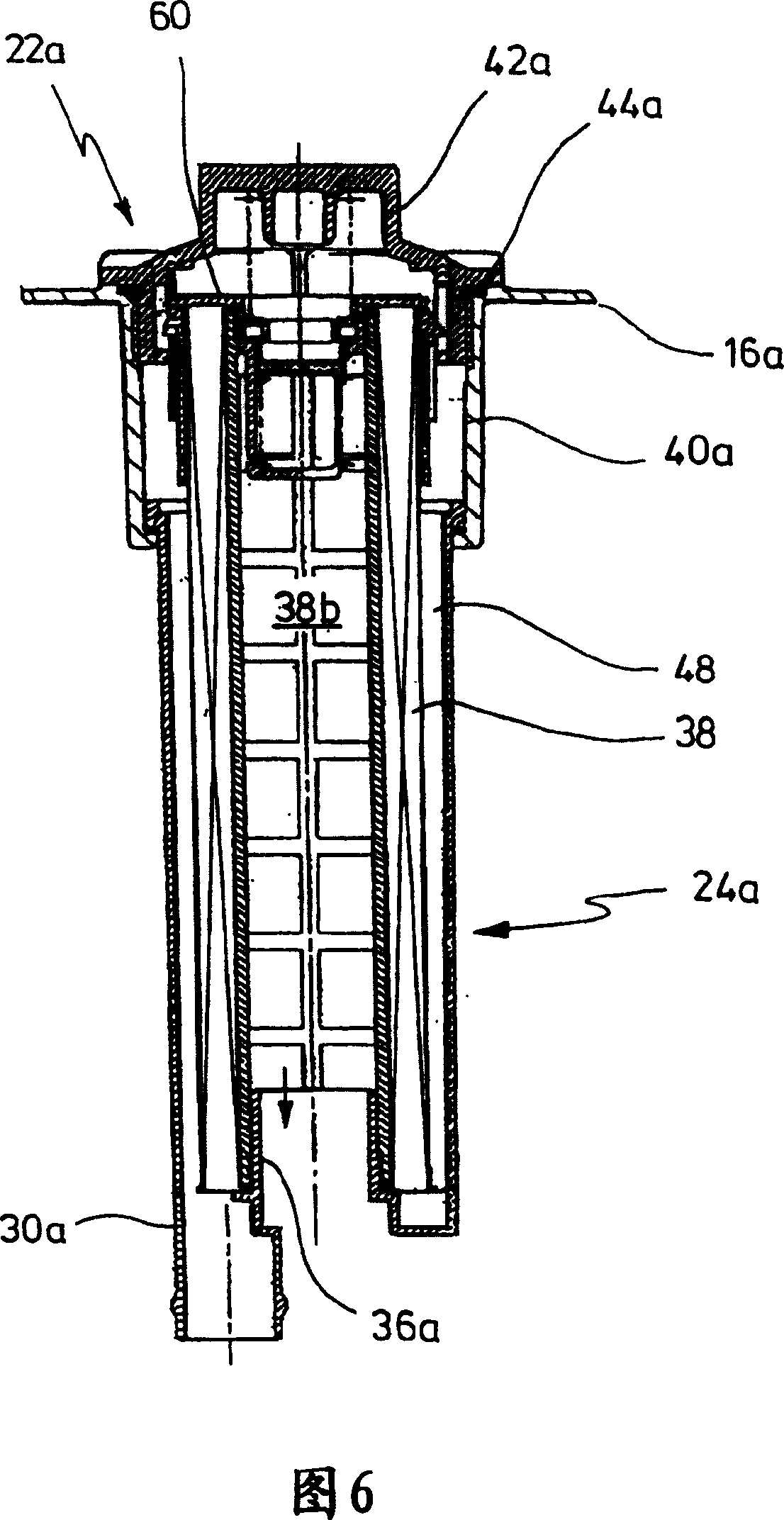

[0016] In Figures 1 to 3 a compact hydraulic unit 10 is shown with an electric motor pump unit 12 having a common housing. A valve housing 14 is secured to the casing of the motor pump unit 12, by means of which the motor pump unit 12 is mounted on the upper side of a hydraulic tank 16. A solenoid valve 18 is attached to the valve box 14 . For example, the hydraulic unit described is used to actuate a lift cylinder (not shown) in an industrial truck. When the motor of the motor pump device 12 is turned on, the liquid medium is delivered to the lifting cylinder from the storage tank 16. The valve element provides a check valve which prevents backflow of liquid media and maintains the lift cylinder at the set position. Activating the solenoid valve 18, the liquid medium will flow back from the lift cylinder, ie through a hose 20, which is shown in dashed lines in FIGS. 2 and 3 . Hoses are located within the tank 16 and lead to a filter unit 22 which will be described in more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com