Cable connector and producing method thereof

A cable connector and cable technology, which is applied in the direction of connection, contact box/base manufacturing, conductive connection, etc., can solve the problems of solder falling off, unable to realize signal or power transmission, etc., and achieve the effect of reliable electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

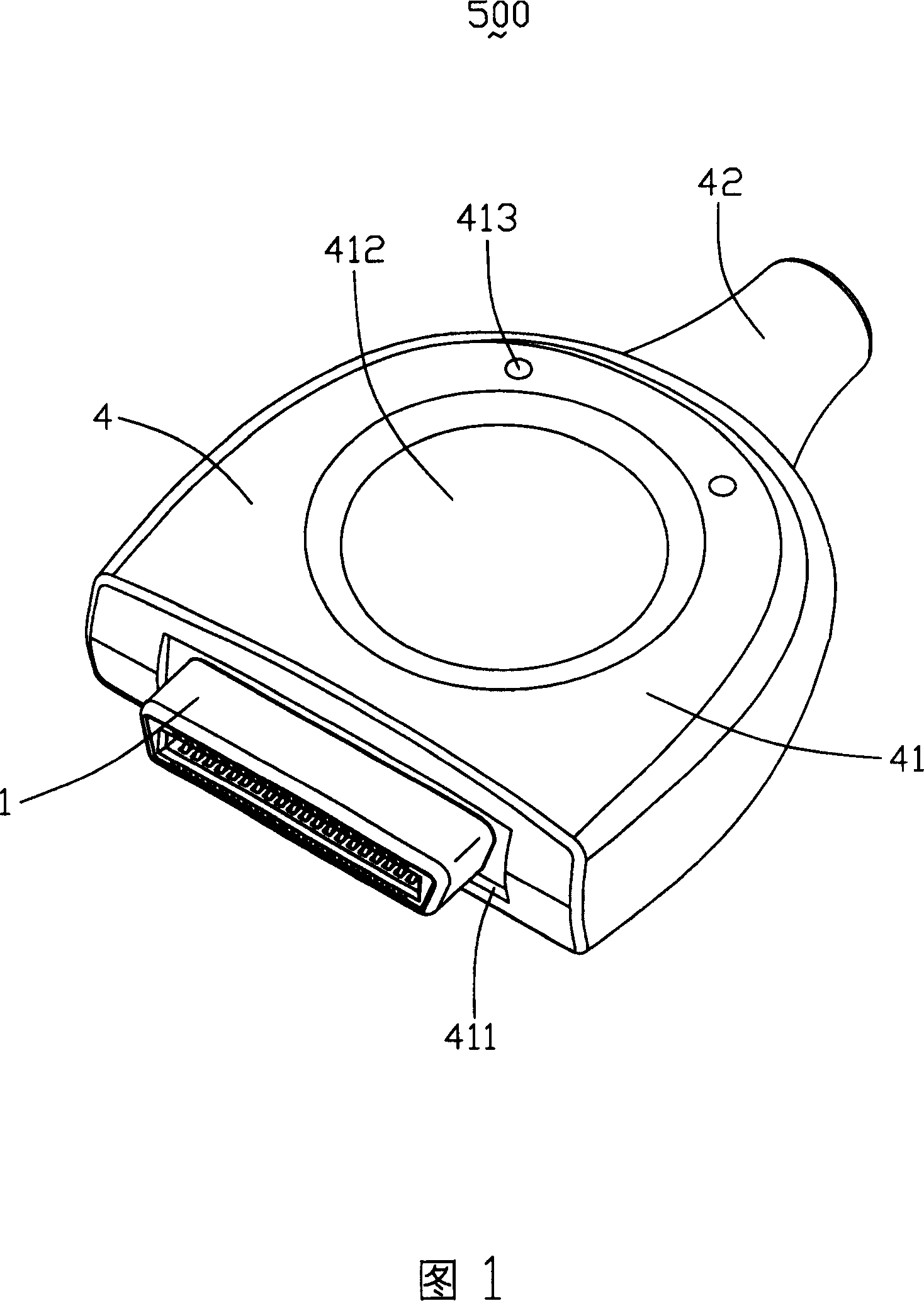

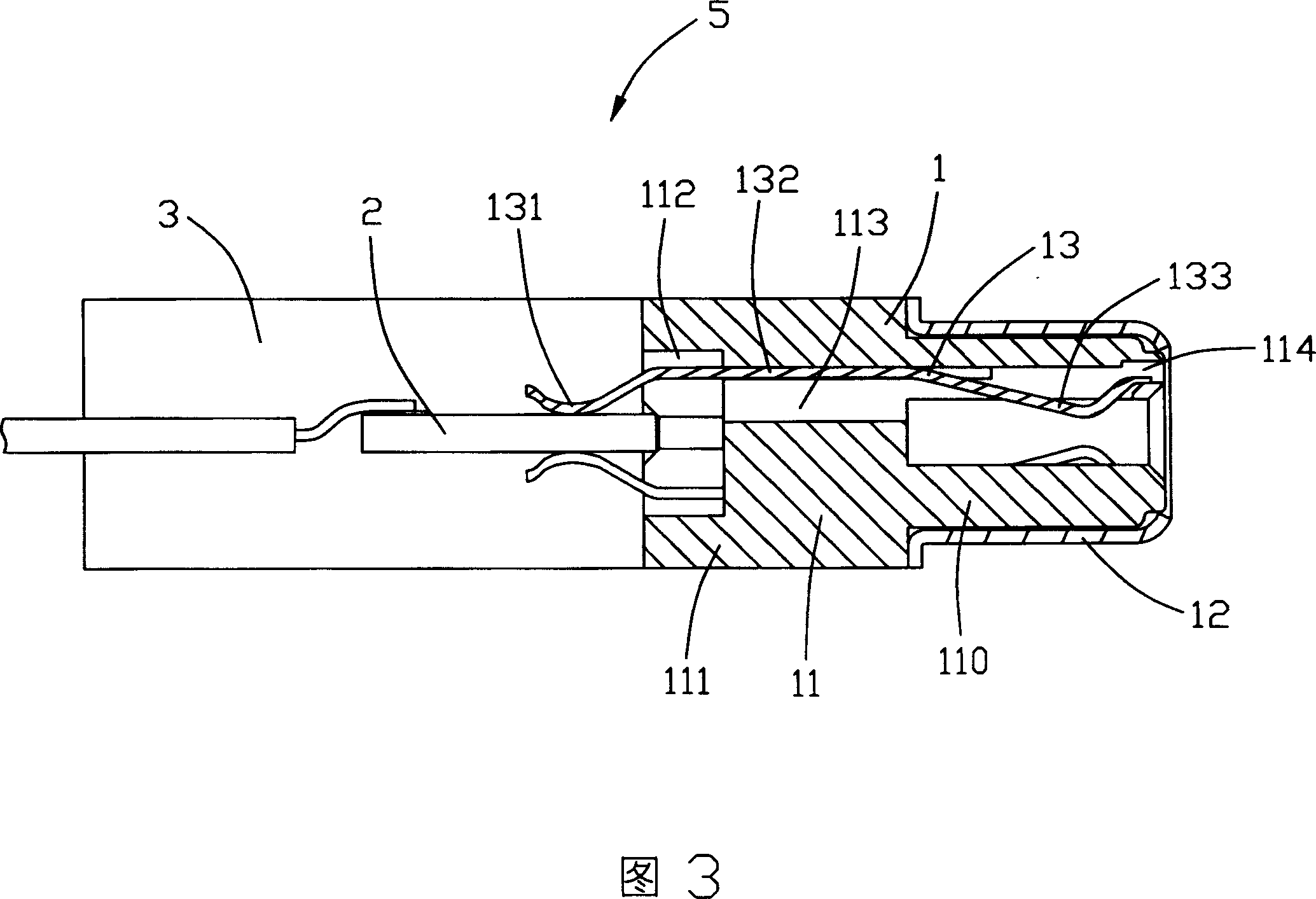

[0010] Please refer to FIG. 1 to FIG. 3 , the manufacturing method of the cable connector 500 of the present invention includes the following steps:

[0011] 1) Provide a plug connector 1 and an internal circuit board 2 , wherein the plug connector 1 includes an insulating body 11 , a conductive terminal 13 accommodated in the insulating body 11 , and a metal shell 12 covering the insulating body 11 . The insulating body 11 is roughly stepped, including a base 111 and an extension 110 extending from the base 111. The extension 110 is provided with a receiving groove 114 for accommodating a pair of connectors (not shown), and the base 111 is provided with a rear space 112 and an upper The bottom two rows communicate with the slots 113 between the receiving groove 114 and the rear space 112 , and the upper and lower surfaces of the base 111 are respectively provided with a plurality of buckling parts 115 . Each conductive terminal 13 includes a number-shaped welding portion 131,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com