Crystal circle center correcting device and correcting method

A calibrator and wafer technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc., can solve problems such as uneven wafer response, and achieve rapid and improved wafer center calibration methods Uniformity, the effect of solving the non-uniformity of wafer reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

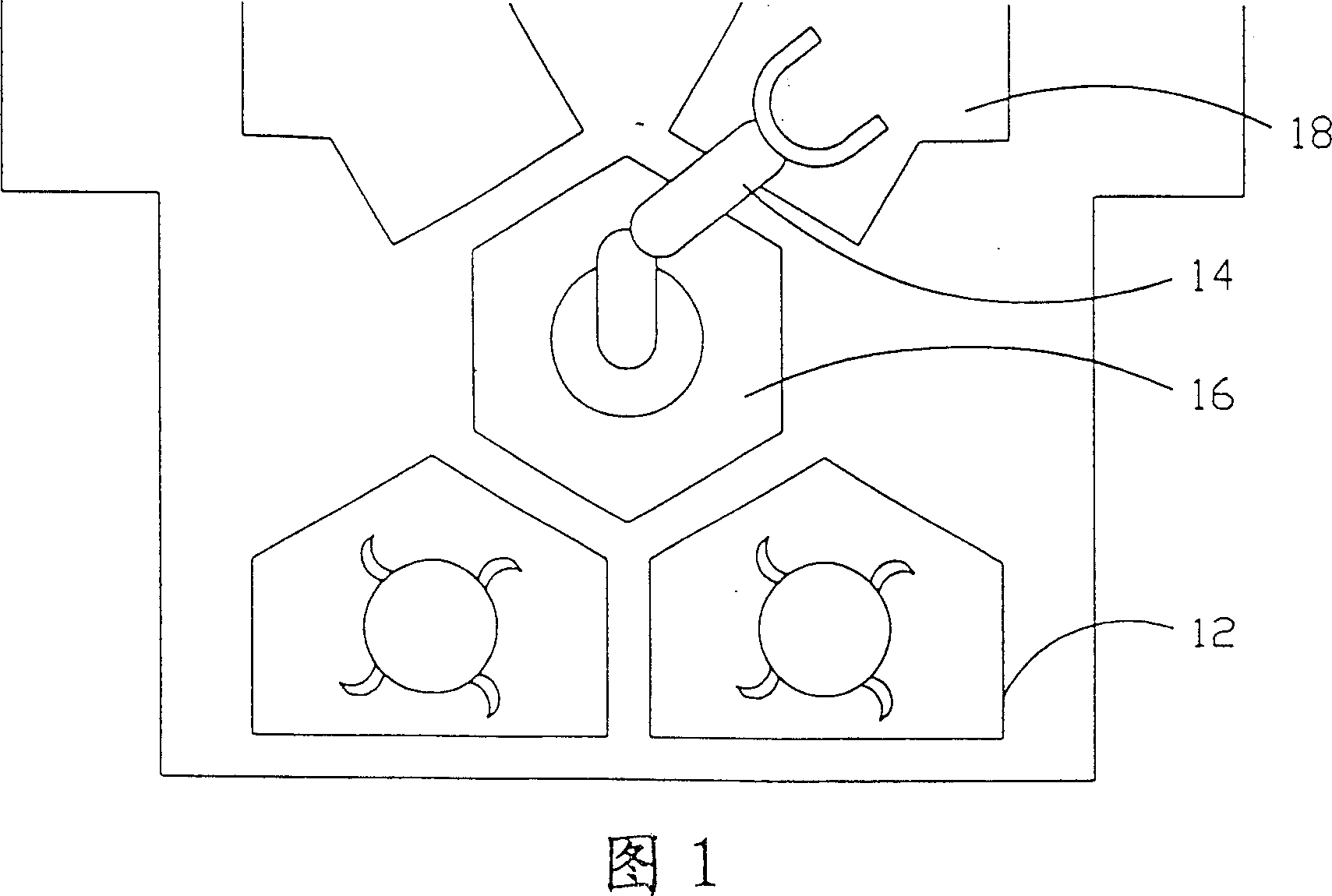

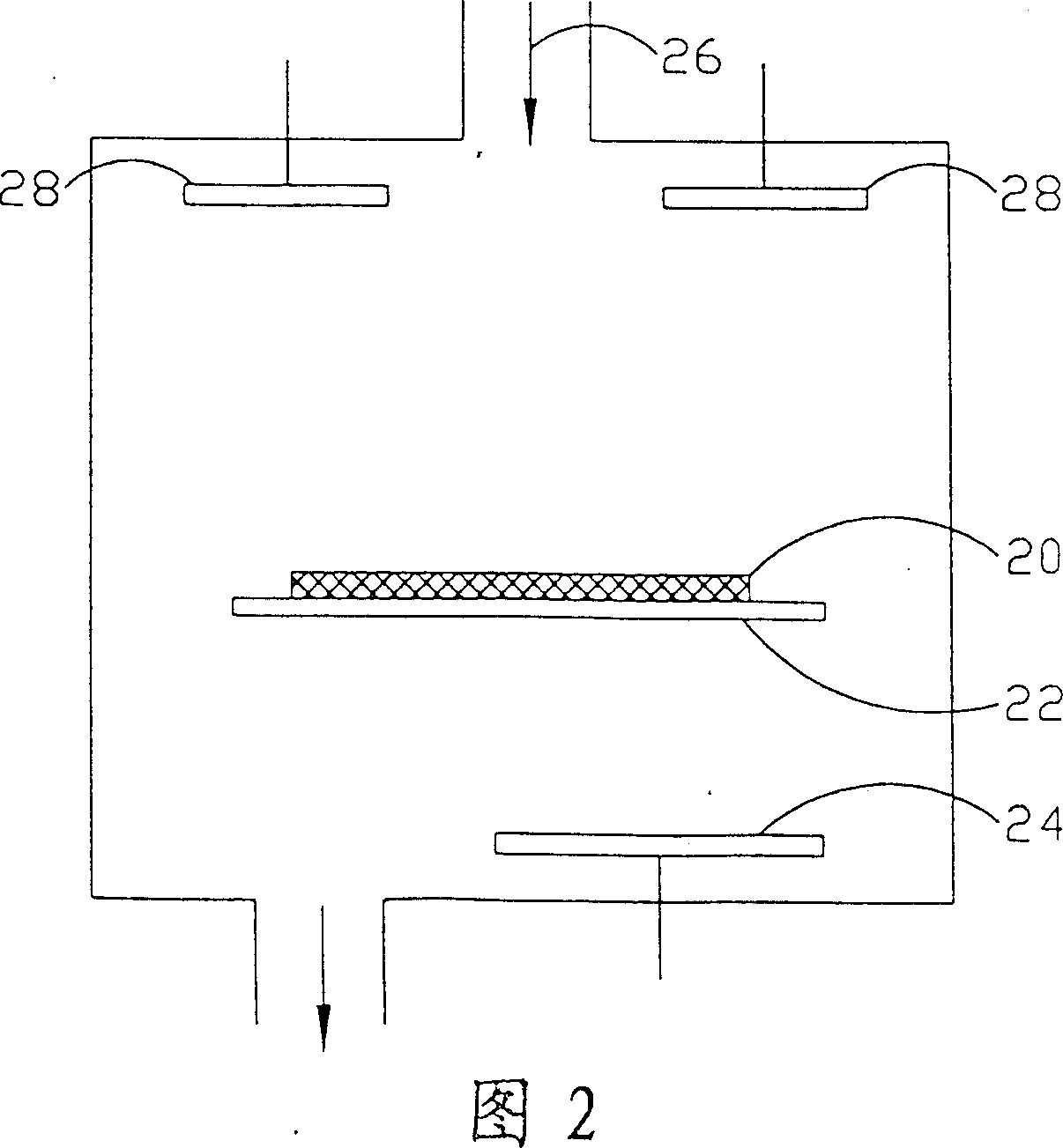

[0018] The preferred embodiment of the wafer center corrector proposed by the present invention will be described in detail as follows. However, in addition to the detailed description, the present invention can also be widely implemented in other embodiments, and the scope of the present invention is not limited. The patent scope of the claims of the present invention shall prevail.

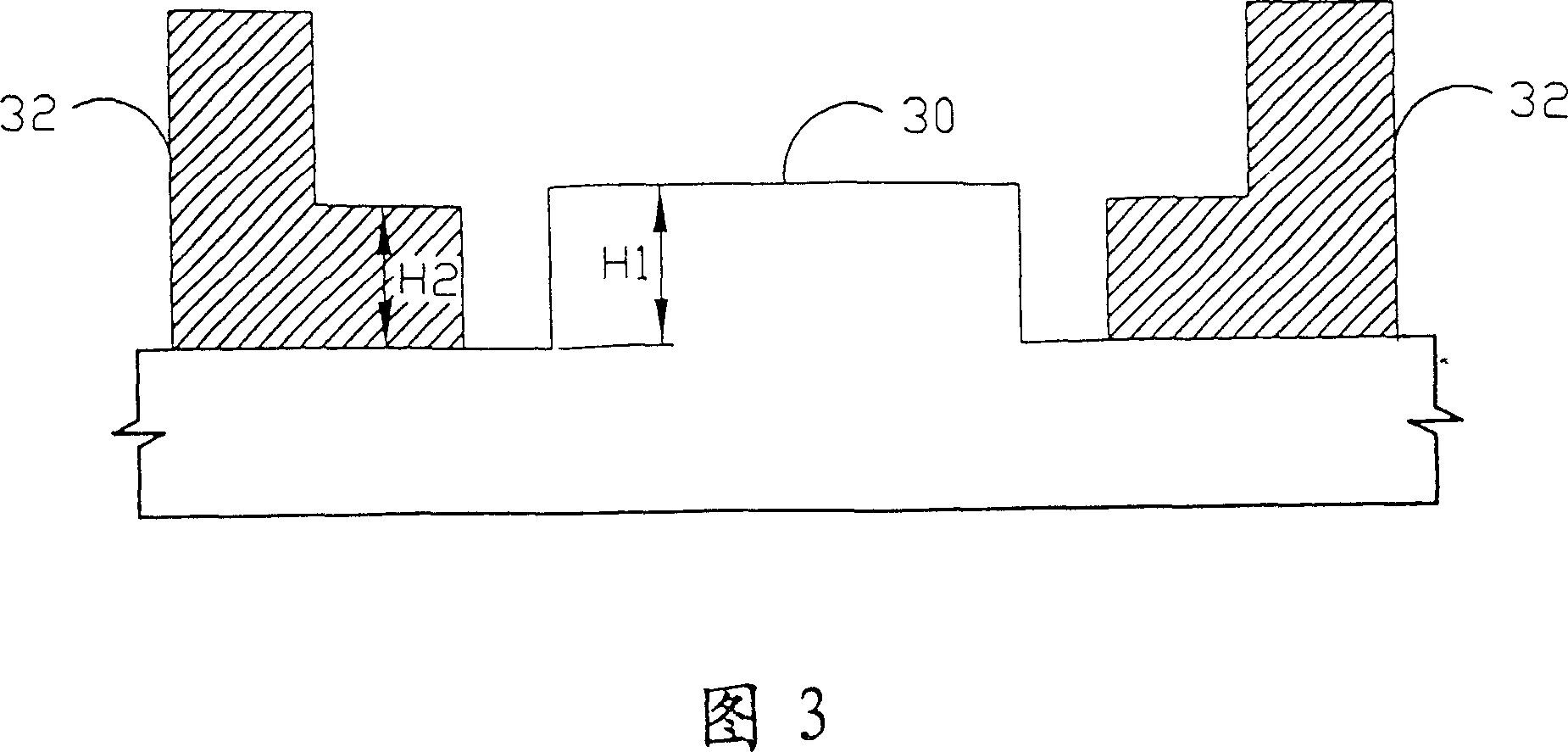

[0019] The wafer center corrector of the present invention is used to correct the assembly error of the focus ring in the etching or deposition reaction chamber, and it at least includes an arc-shaped bottom rib of the wafer center corrector, and the radius of curvature of the arc-shaped bottom rib is consistent with that of the electrostatic chuck and The radius of curvature of the focus ring is the same. When in use, the wafer center corrector is placed on the electrostatic chuck and the focus ring, so that the bottom rib of the wafer center corrector is placed in the approximate annular gap fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com