Method for improving refractive index distribution of self-focusing lens

A technology of refractive index distribution and self-focusing lens, which is applied in the field of improving the refractive index distribution of self-focusing lens, and can solve the problems of large aberration of self-focusing lens, large exit spot size, and affecting the quality of self-focusing lens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

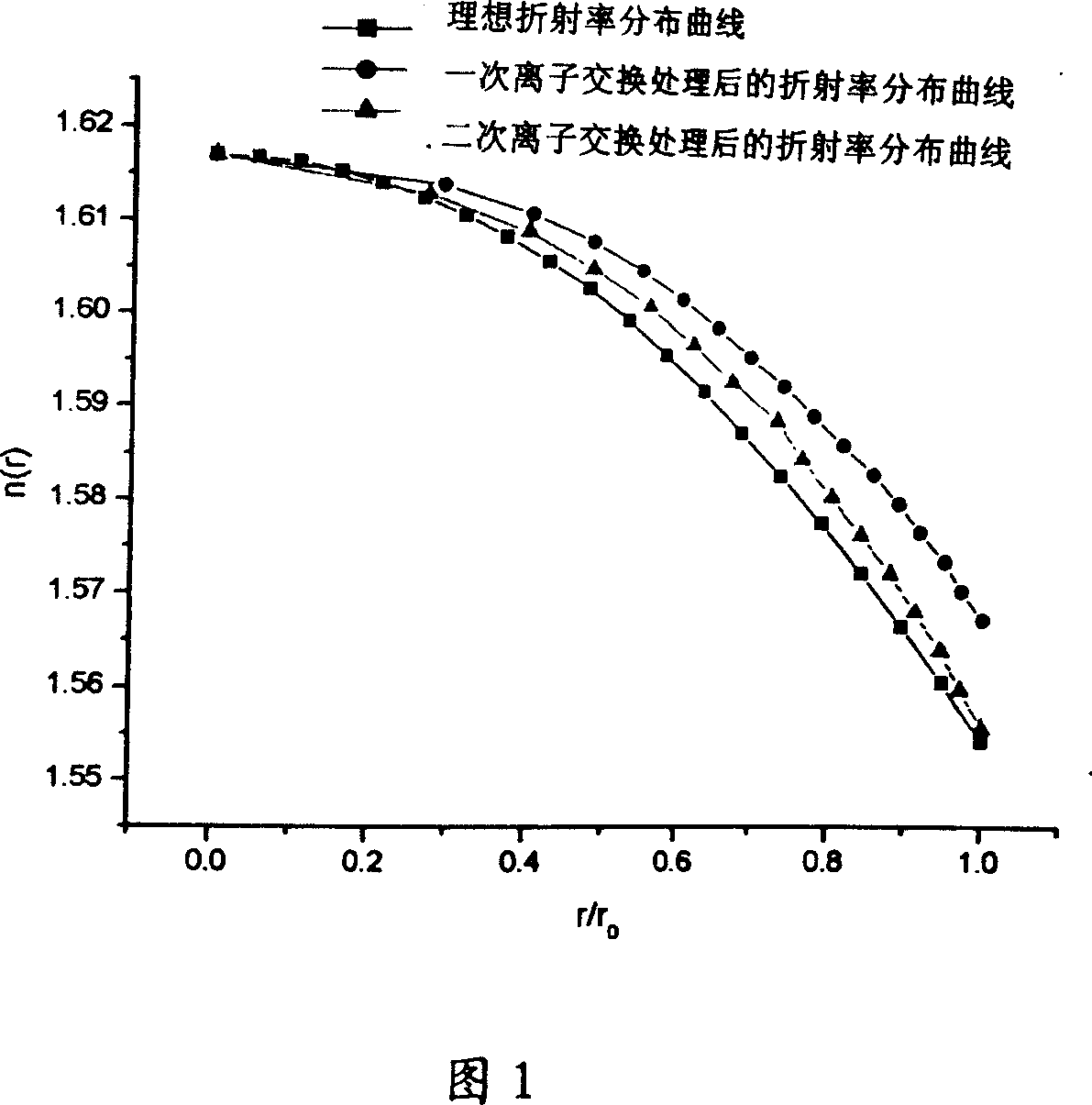

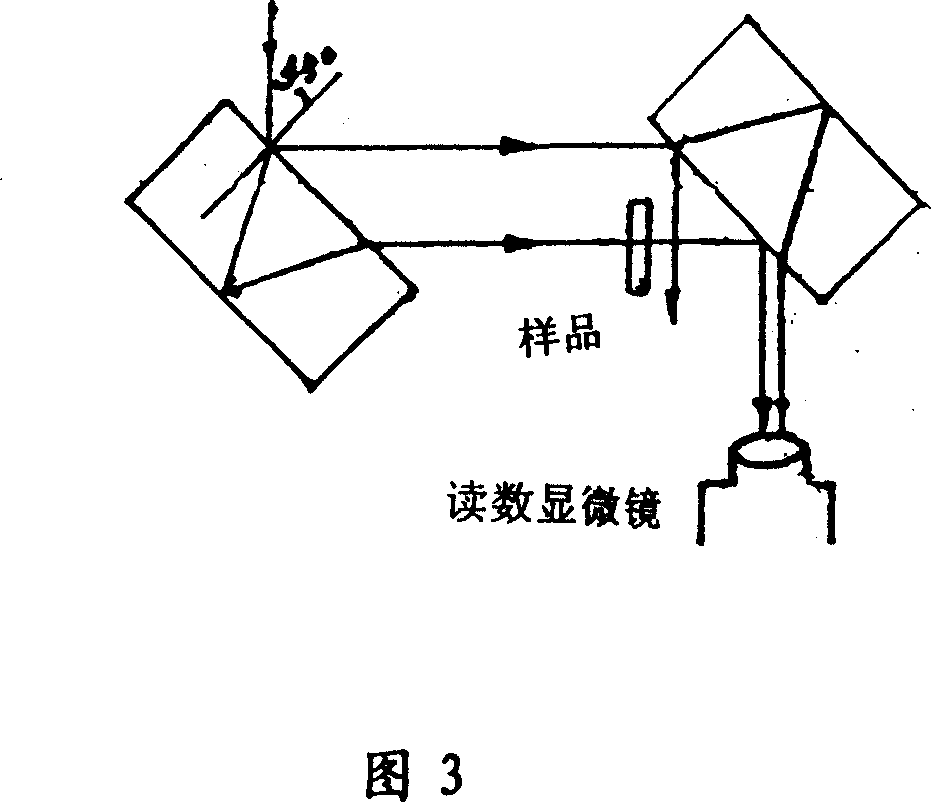

[0020] Example 1: Referring to Figure 1, the refractive index distribution of the self-focusing lens sample NO 01 after the first ion exchange was measured by thin-section interferometry, and the distortion and spherical aberration of the sample were measured. The measurement result shows that the sample is negative spherical aberration and barrel-shaped Distortion, the refractive index distribution of its edge is higher than the ideal refractive index distribution. In order to improve the refractive index distribution at the edge, the purpose of the second ion exchange treatment is to reduce the refractive index at the edge of the self-focusing lens to make it closer to the ideal refractive index distribution. Therefore, in the secondary ion exchange, the molten salt used is a mixed salt of 3% NaNO3 and 97% KNO3, and the ion exchange temperature is 530°C±0.5°C. In order to only correct the refractive index distribution at the edge of the lens, the secondary ion exchange The t...

Embodiment 2

[0021] Example 2: Except that the secondary ion exchange time was changed to 25 minutes, the others were the same as in Example 1. For the self-focusing lens sample NO 02 after the secondary ion exchange, the refractive index distribution and aberration characteristics were measured, and the measurement The results show that the barrel distortion is reduced from the original 0.160 to 0.073, and the longitudinal spherical aberration is reduced from the original 0.210 to 0.190, which obviously improves the refractive index distribution and aberration characteristics of the edge of the self-focusing lens.

Embodiment 3

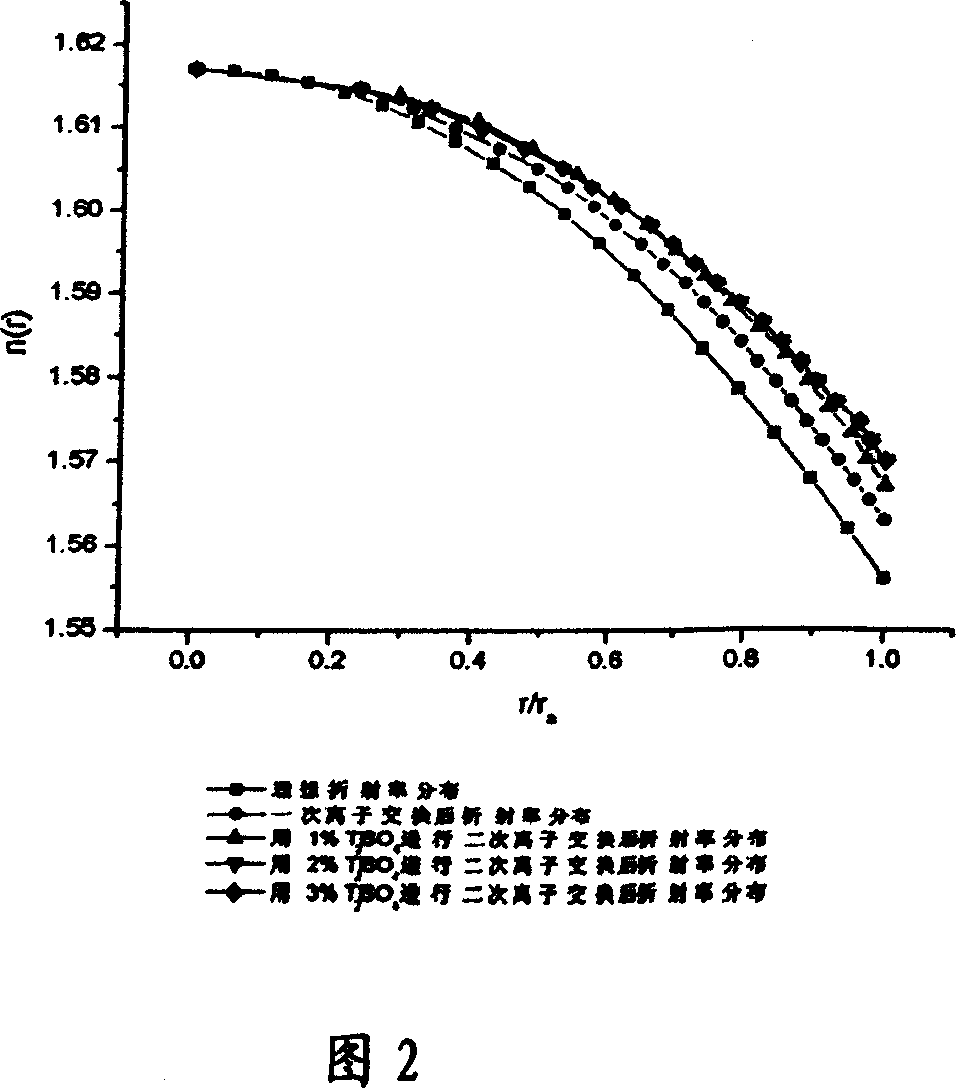

[0022] Example 3: The refractive index distribution of the self-focusing lens sample NO 01 after the first ion exchange was measured by thin-section interferometry, and the distortion and spherical aberration of the sample were measured. The measurement results showed that the sample had negative spherical aberration, barrel distortion, and its edge The refractive index profile of the part is higher than the ideal refractive index profile. In order to improve the refractive index distribution at the edge, the purpose of the second ion exchange treatment is to reduce the refractive index at the edge of the self-focusing lens to make it closer to the ideal refractive index distribution. Therefore, in the secondary ion exchange, the molten salt used is 2% NaNO 3 with 98% KNO 3 The mixed salt, the ion exchange temperature is 530°C±0.5°C, in order to only correct the refractive index distribution at the edge of the lens, the secondary ion exchange time is 30 minutes. For the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com