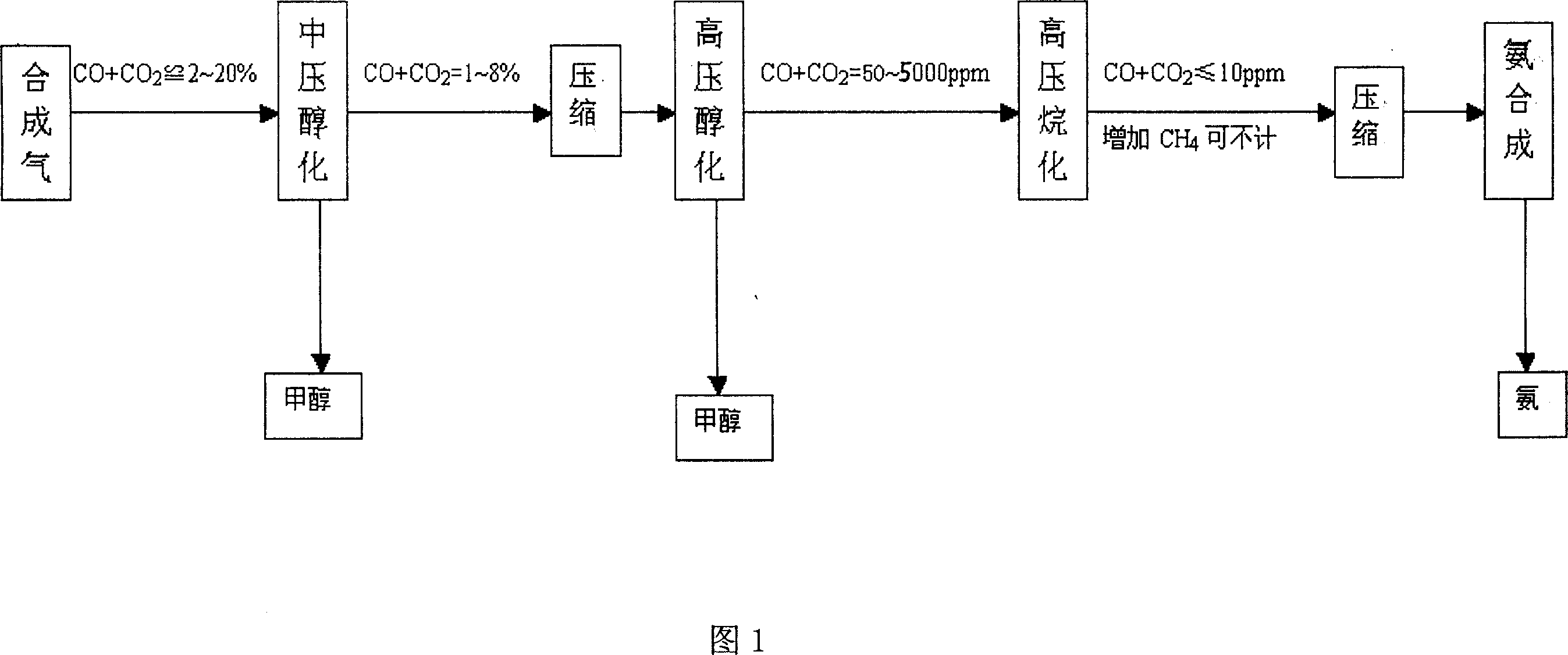

Non-isostatic alcoholization alkylation process for purifying raw gas for ammonia synthesis

A raw material gas and new process technology, applied in the field of synthetic ammonia, can solve the problems of large economic loss, increased compression work, and high consumption, and achieve the effects of reducing production costs, high purification, and ensuring refining requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Pass the synthesis gas into the φ1200mm medium-pressure alcoholization tower, the pressure is 15Mpa, the temperature is controlled at 210-270°C, so that it contains 3-10% CO+CO 2 The synthetic gas is synthesized into methanol under medium pressure, and the CO+CO is exported 2 Control it at 1-4%, pressurize, send the pre-purified synthesis gas into a φ1000mm high-pressure alcoholization tower, the pressure is 30.0Mpa, the temperature is controlled at 210-270°C, so that 1-4% CO+CO in the synthesis gas 2 Convert to methanol, export CO+CO 2 Control at ≤200ppm, send the deeply purified synthesis gas into a φ800mm high-pressure alkylation tower for alkylation, control the pressure at 30.0Mpa, control the temperature at 230-300°C, and export CO+CO 2 For <10ppm, the synthesis gas enters the ammonia synthesis. The alcohol ammoniation of the system is 0.1-0.4.

Embodiment 2

[0041] Pass the synthesis gas into the φ1600mm medium-pressure alcoholization tower, the pressure is 12.0Mpa, the temperature is controlled at 210-260°C, so that it contains 2-3% CO+CO 2 The synthetic gas is synthesized into methanol under medium pressure, and the CO+CO is exported 2 Control at 1.0-2.0%, pressurize, send the preliminarily purified synthesis gas into a φ1400mm high-pressure alcoholization tower, the pressure is 23.0Mpa, the temperature is controlled at 210-260°C, so that 1.0-2.0% CO+CO in the synthesis gas 2 Convert to methanol, export CO+CO 2 Control at ≤600ppm, send the deeply purified synthesis gas into a φ1400mm high-pressure alkylation tower for alkylation, control the pressure at 23.0Mpa, control the temperature at 250-350°C, and export CO+CO 2 ≤10ppm, the synthesis gas enters the ammonia synthesis. The alcohol ammoniation of this system is 0.06~0.2.

Embodiment 3

[0043] Pass the synthesis gas into the φ1200mm medium-pressure alcoholization tower, the pressure is 5Mpa, the temperature is controlled at 210-280°C, so that it contains 5-10% CO+CO 2 syngas to methanol, export CO+CO 2 Control it at 2-6%, pressurize, send the pre-purified synthesis gas into a φ1000mm high-pressure alcoholization tower, the pressure is 16.0Mpa, the temperature is controlled at 210-280°C, so that 2-6% CO+CO in the synthesis gas 2 Convert to methanol, export CO+CO 2Control at ≤4000ppm, send the deeply purified synthesis gas into a φ800mm high-pressure alkylation tower for alkylation, control the pressure at 30.0Mpa, control the temperature at 250-350°C, and export CO+CO 2 For <10ppm, the synthesis gas enters the ammonia synthesis. The alcohol ammoniation of this system is 0.4~1.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com