Fuel supply device for IC engine

A diesel engine and fuel technology, which is applied to fuel injection devices, charging systems, mechanical equipment, etc., can solve problems such as unreliable devices, poor fuel atomization, and wear, to prevent unwanted accumulation, ensure high reliability and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

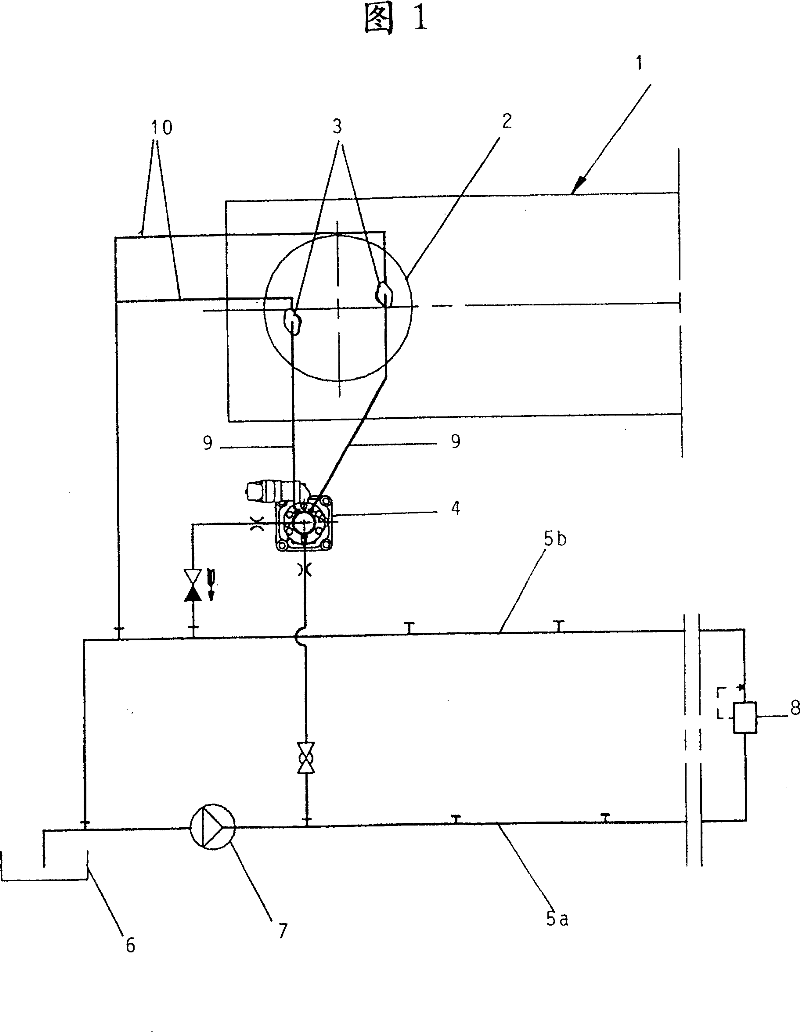

[0021] FIG. 1 schematically shows an internal combustion engine 1 , which may be a large two-stroke diesel engine, for example used as a marine power plant, comprising a plurality of cylinders 2 , only one of which is shown in FIG. 1 . Two fuel injectors 3 are provided per cylinder 2 , to which a common fuel injection pump 4 is always assigned. A common oil supply circuit is arranged for the fuel injection pumps 4 of all the cylinders 2. This oil supply circuit has a precursor branch line 5a and a return flow branch line 5b and is provided with a fuel tank 6, a preparation pump 7 and a pressure regulating valve 8. In the illustrated example, the oil supply circuit 5 is set at a pressure of 8 bar in the precursor branch line 5 a before the pressure regulating valve 8 , and the pressure in the return branch line 5 b after the pressure regulating valve 8 is 4 bar. The suction side of the fuel pump 4 is connected to the forward branch line 5a of the fuel supply circuit, and its re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com