Cutting edge construction used in perforating device

A technology of punching device and cutting edge, applied in metal processing and other directions, can solve the problems of being stuck, spending a lot of effort, and difficult to remove debris from the penetrated object.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

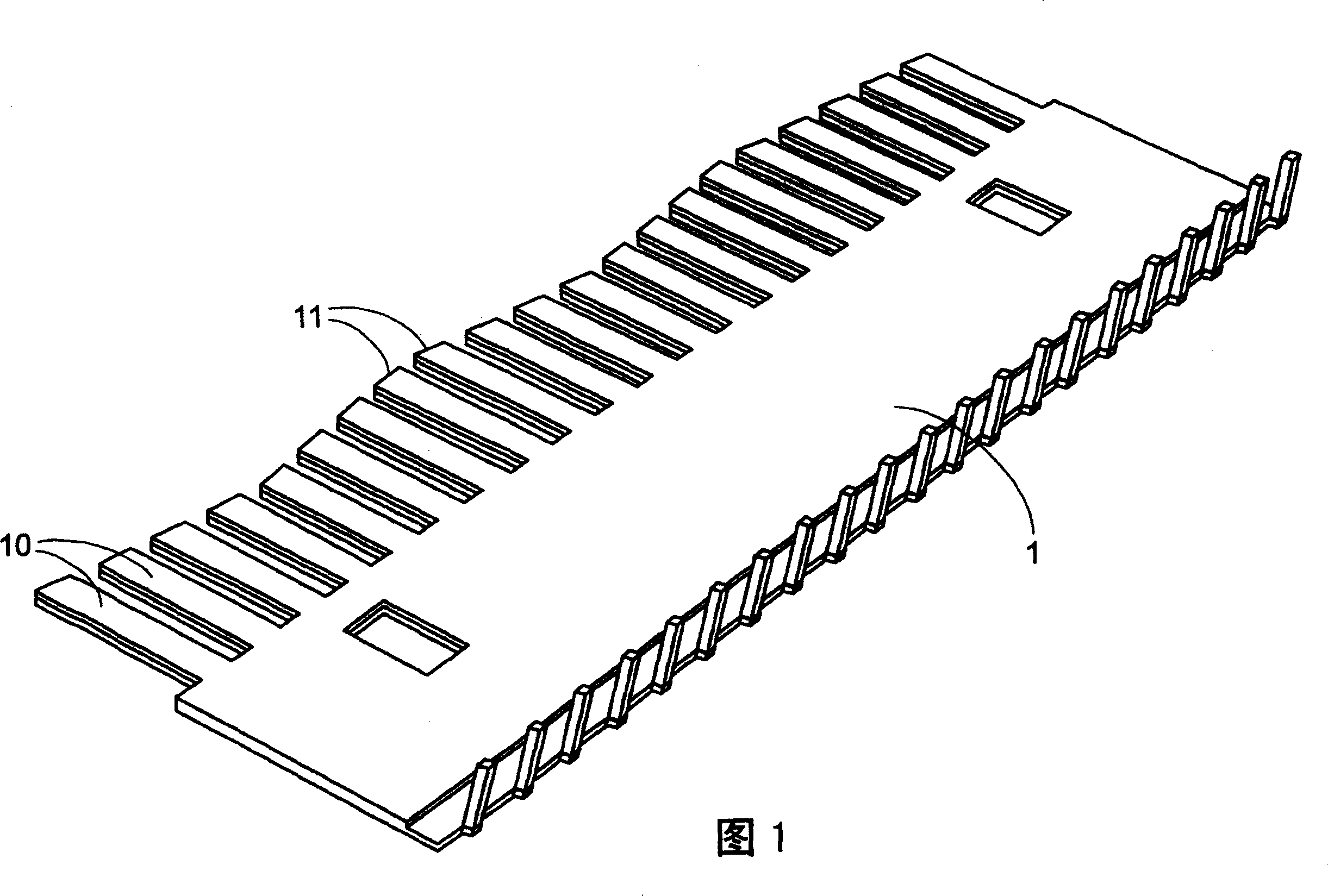

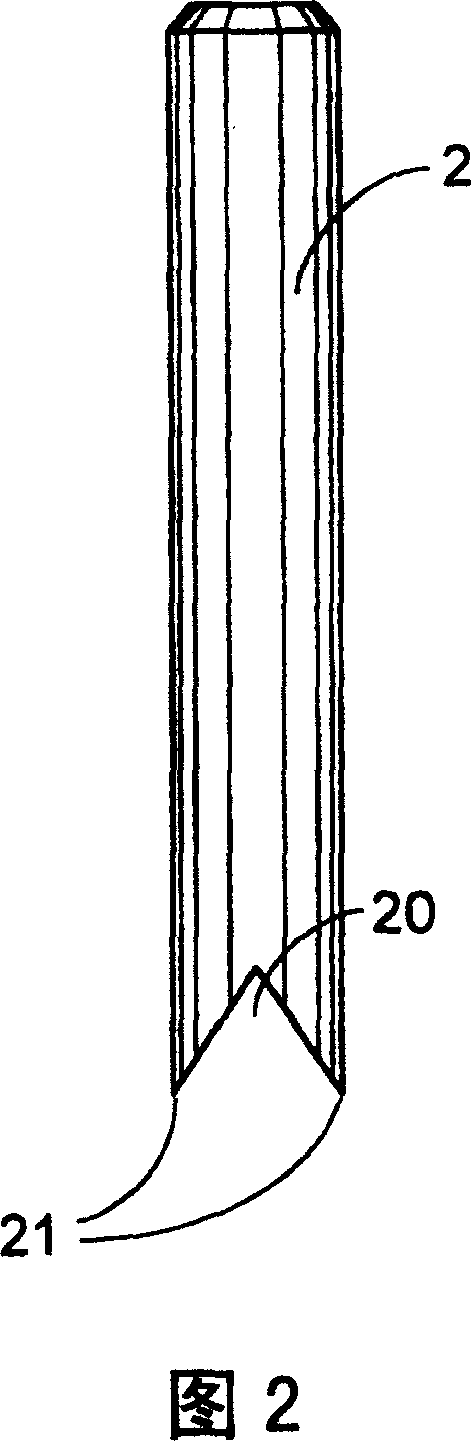

[0028] This embodiment is mainly applied to the blade and the matching knife seat in the punching device, wherein the blade includes several blades for punching, and the blade consists of a main body; a first piercing end; a second a piercing end; and a cutting concave surface. And this knife seat mainly comprises a knife seat main body and several knife seat holes that cooperate with the blade on the blade.

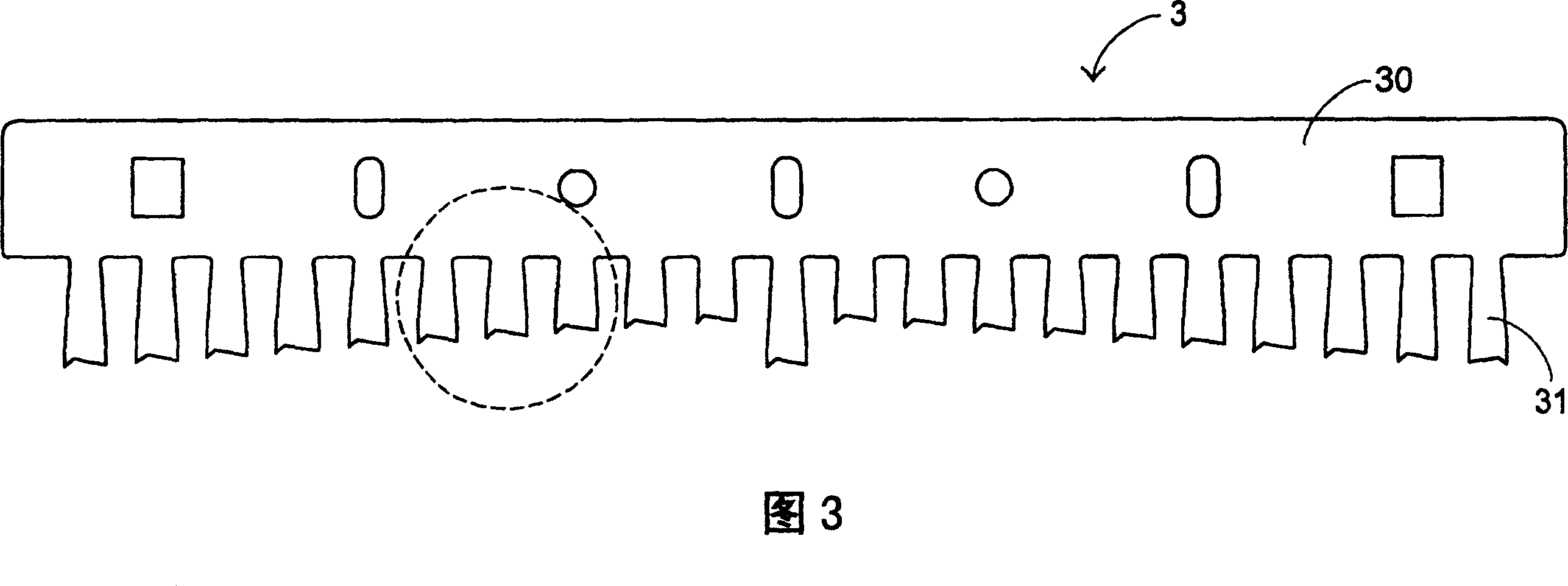

[0029] Please refer to Fig. 3, Fig. 4 and Fig. 5, which are the front schematic diagram of the blade part, the partial enlarged schematic diagram and the three-dimensional schematic diagram of the blade structure of this embodiment, which depict the blade (punching plate) 3 and the knife seat used in the punching device (die plate)5.

[0030] Can further refer to Fig. 3, its blade 3 mainly comprises a blade main body 30 and several blades 31 for punching holes, in the present embodiment, the blade 31 of this blade 3 is arranged in such a way that the length of the blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com