Inorganic spinning additive and its application method

An application method and additive technology, applied in the fields of application, tobacco, smoke oil filter elements, etc., can solve the problem of insufficient functional materials, achieve the effects of increasing the degradation rate, increasing the specific surface area, and improving the adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

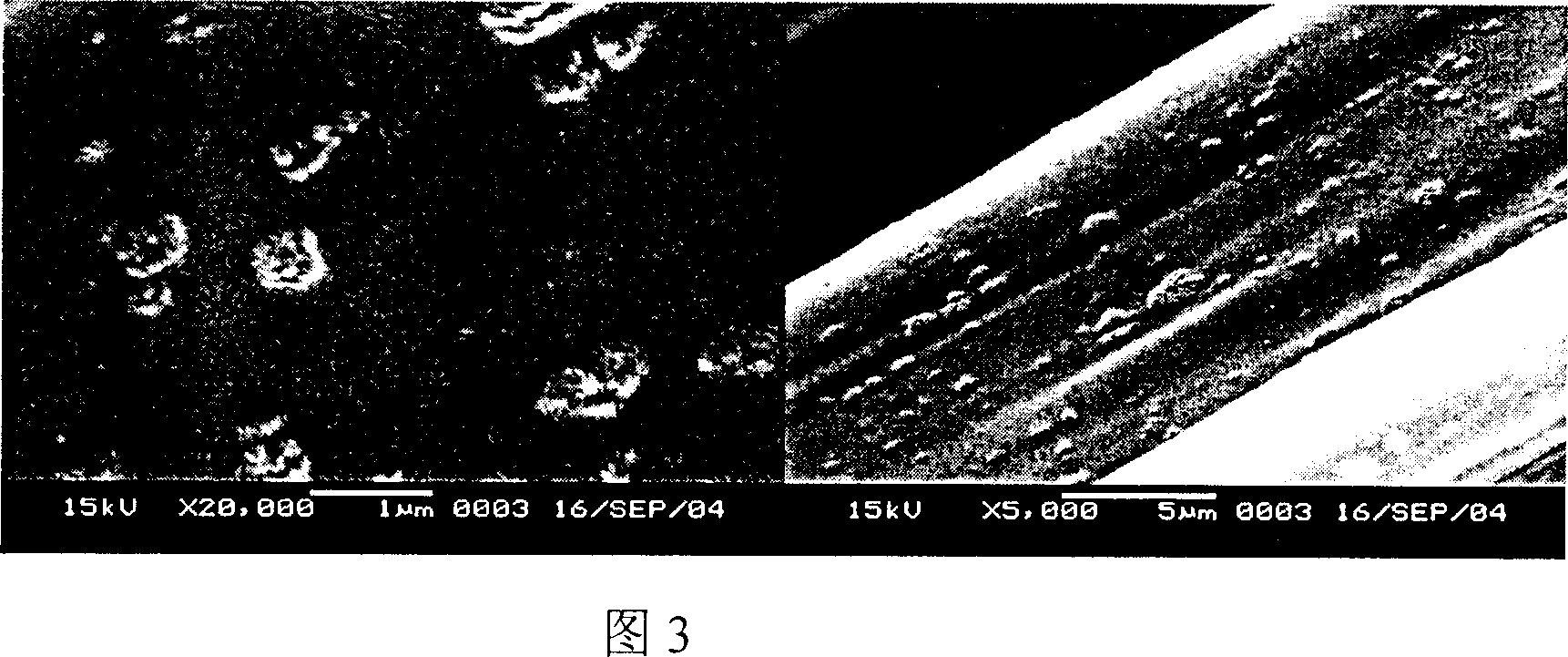

Embodiment 1

[0018] The first process of cellulose acetate tow products is the synthesis of cellulose diacetate. The process includes: wood pulp-crushing, drying-acetic acid-aging-precipitation-water washing, drying-mixing, seven processes, after synthesis, vinegar The sheet goes through the second process, namely the spinning process, which includes: dissolving-filtering and defoaming-spinning-curling, crumpling-drying and packing, during which there is also a recovery process for the solvent acetone. In this experiment, 0.1-5 μm di Silica is mainly added in the second process, that is, the "dissolving" process of the spinning process. After the 0.1-5μm silica reacts with the silane coupling agent TEOS, it can be evenly dispersed in acetone and water without being filtered out. . Therefore, it can be directly added to the slurry of cellulose acetate dissolved in acetone. In 550 kg of cellulose diacetate acetone spinning slurry, it contains 27% of cellulose diacetate, and 0.1-5 μm of silic...

Embodiment 2

[0029] In 500 kg of diacetate fiber acetone spinning slurry, containing 30% of diacetate fiber, adding 1 to 2 μm white carbon black additive to account for 7% of diacetate fiber, adding water to account for 5% of diacetate fiber solvent acetone, and spinning.

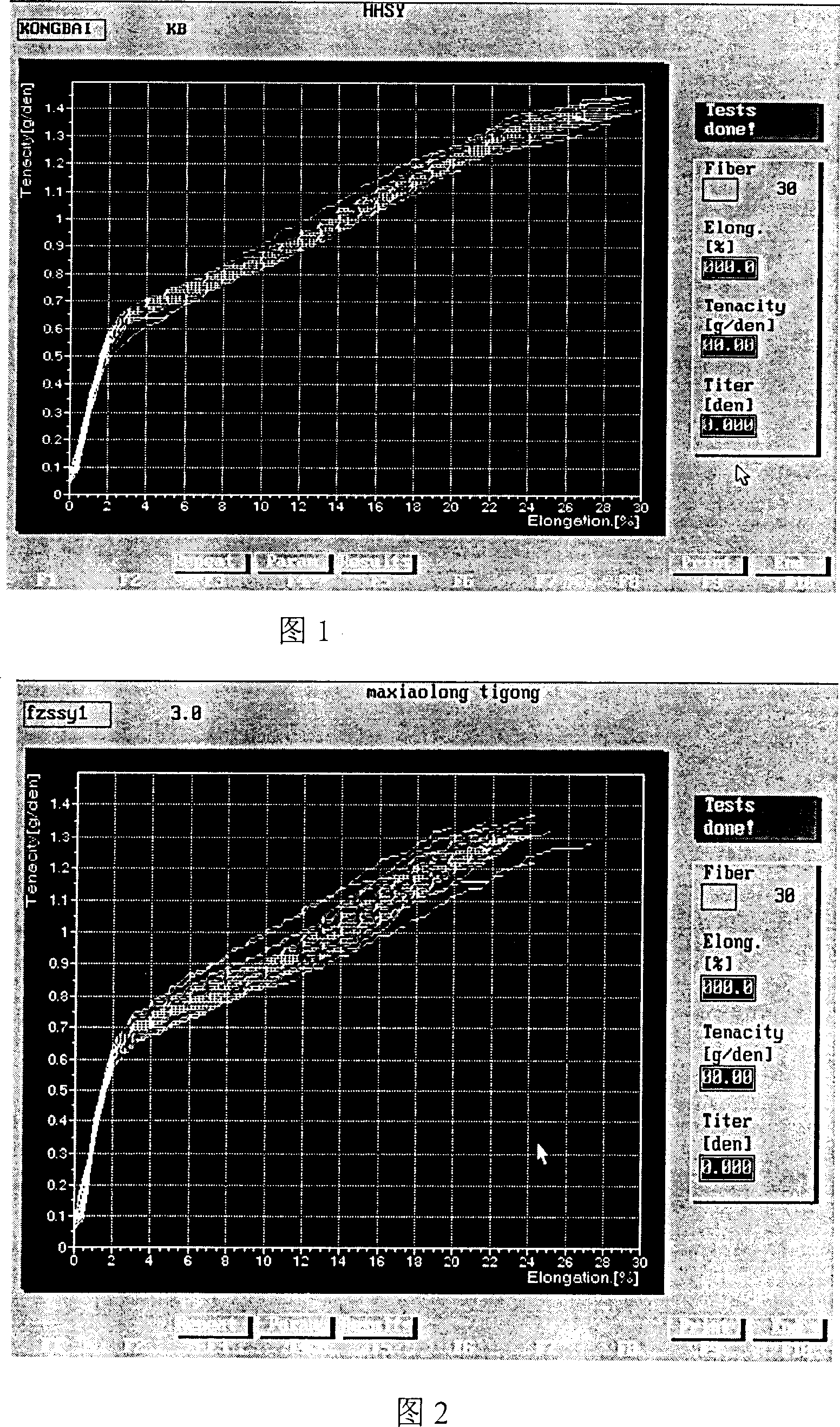

[0030] The main physical properties of the fiber are measured by the INSTRON MODEL 1011-strength meter, the breaking strength and elongation of the total denier of the tow, and the LENZING VN400-single filament strength and fineness meter (determining the breaking strength, denier, elongation, etc. of a single filament) see The following table:

[0031] Single denier Titer(den)

[0032] It can be seen from the above parameters that the additives do not affect the normal spinning of acetate fiber. Only the breaking strength decreases and the elongation at break becomes smaller.

[0033] After the tow is formed by the cigarette filter forming machine, the process parameters of the cigarette filter are the sam...

Embodiment 3

[0037] In 550 kg of diacetate fiber acetone spinning slurry, containing 27% of diacetate fiber, adding 50-100nm silicon carbide additive to account for 10% of diacetate fiber, silane coupling agent KH-560 accounting for 0.1% of the slurry for spinning. The main physical properties of the fiber are shown in the table below:

[0038] Single denier Titer(den)

[0039] It can be seen from the above parameters that the additives do not affect the normal spinning of acetate fiber.

[0040] After the tow is formed by the cigarette filter forming machine, the process parameters of the cigarette filter are the same as those of the above example 1, and after the shredded tobacco is rolled, the results of reducing the coke of the cigarette are compared

[0041] COmg / branch

[0042] It can be seen from the above table that after adding 10% silicon carbide, the tar is reduced by 9 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com