Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Quality and reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

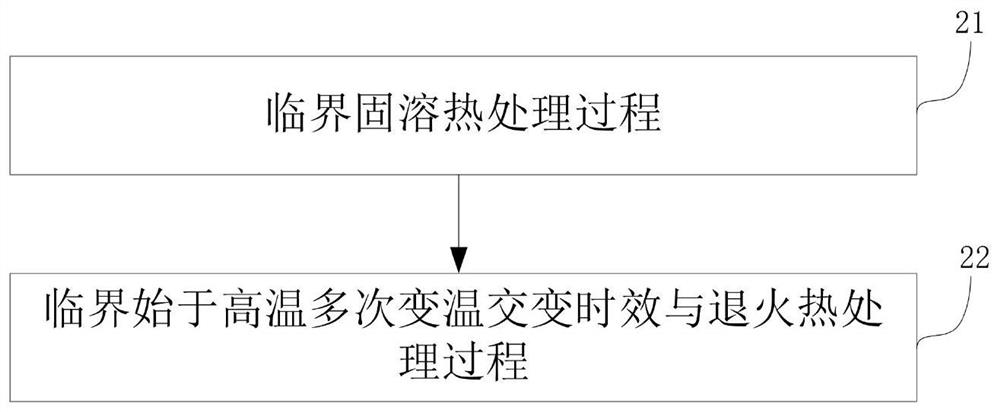

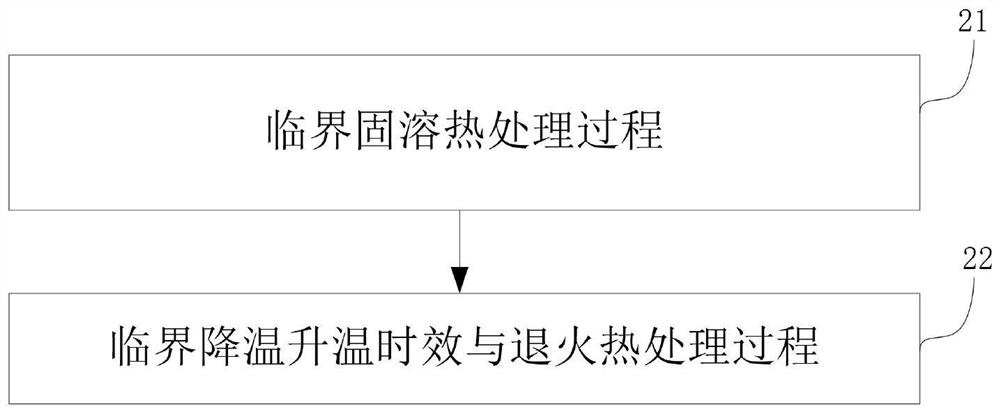

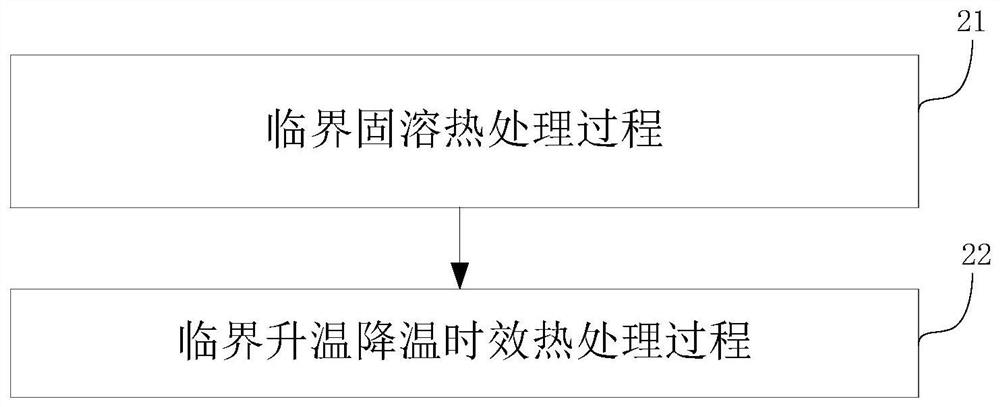

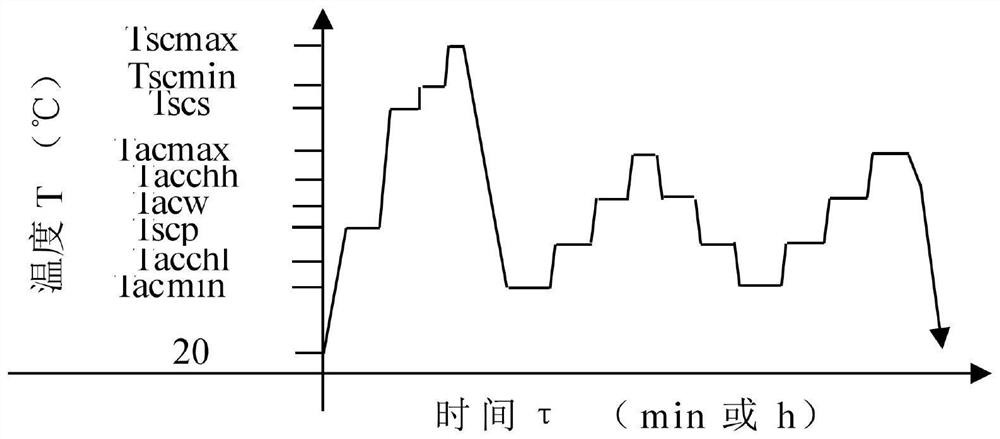

Critical solid solution and critical cooling and heating variable-temperature aging and annealing heat treatment method

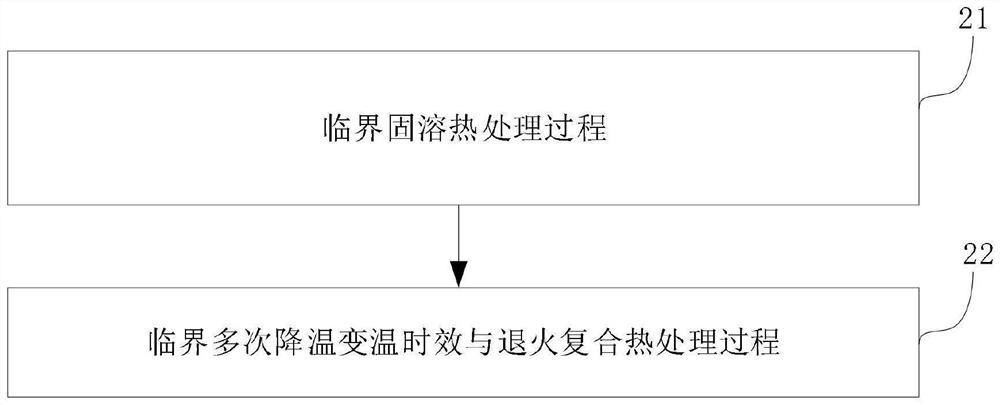

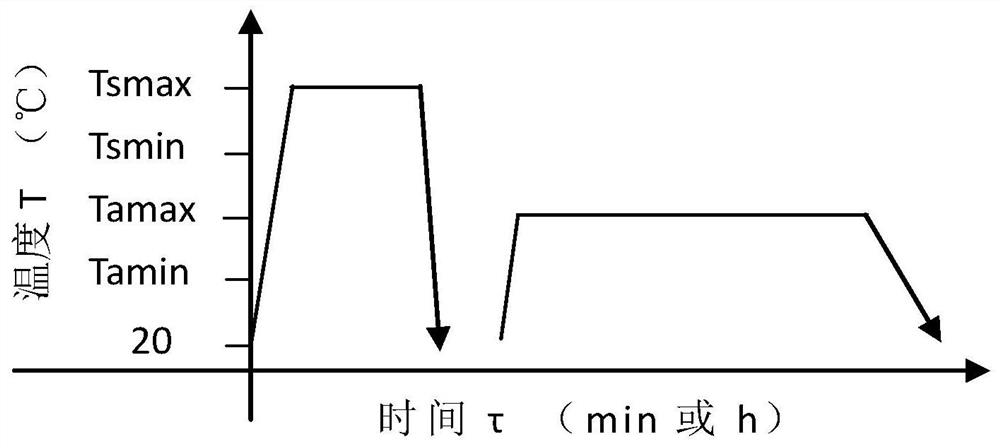

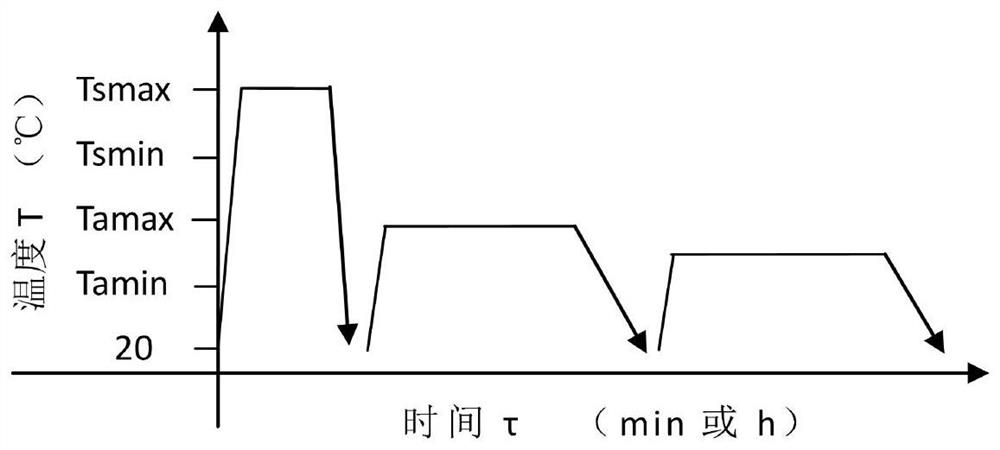

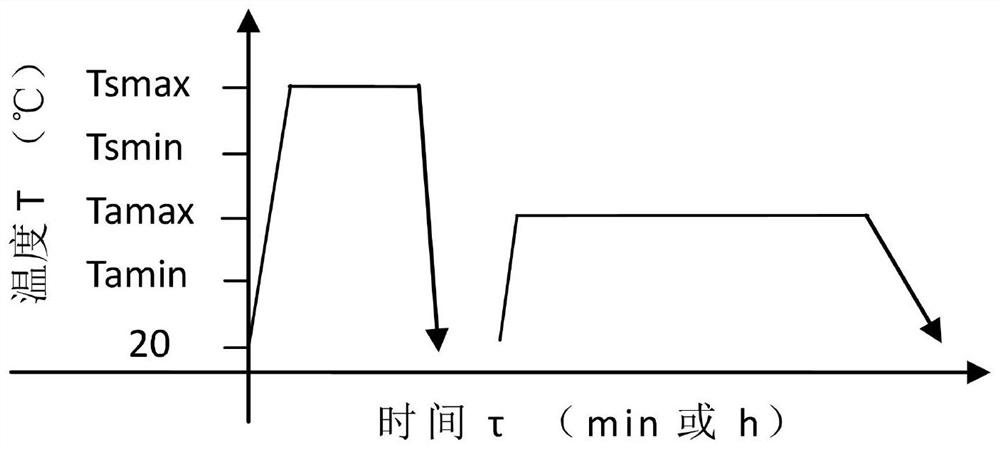

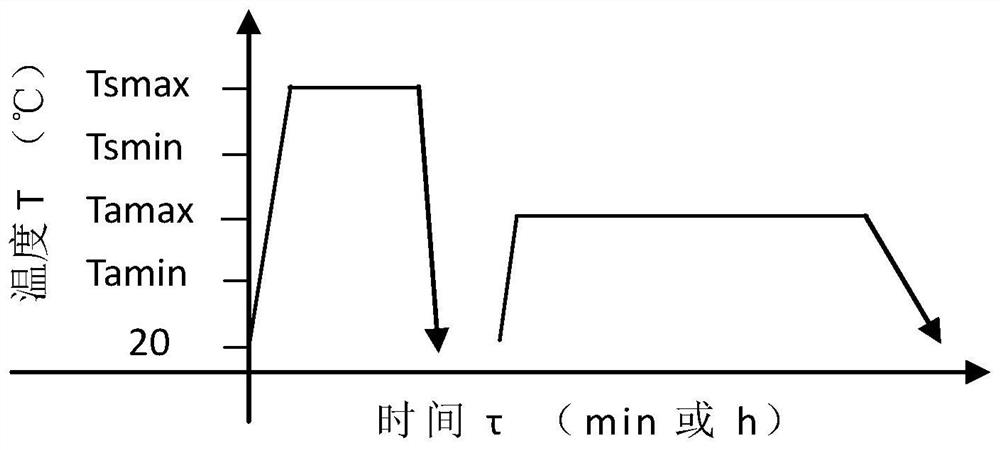

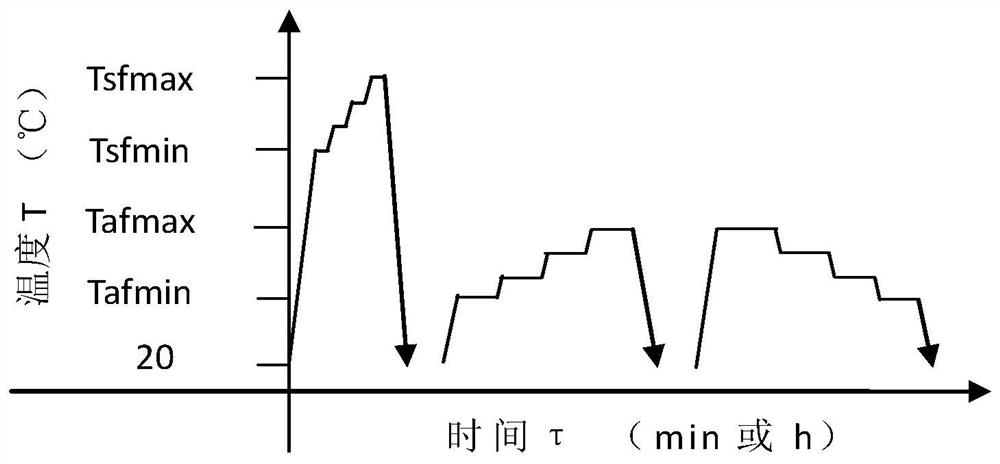

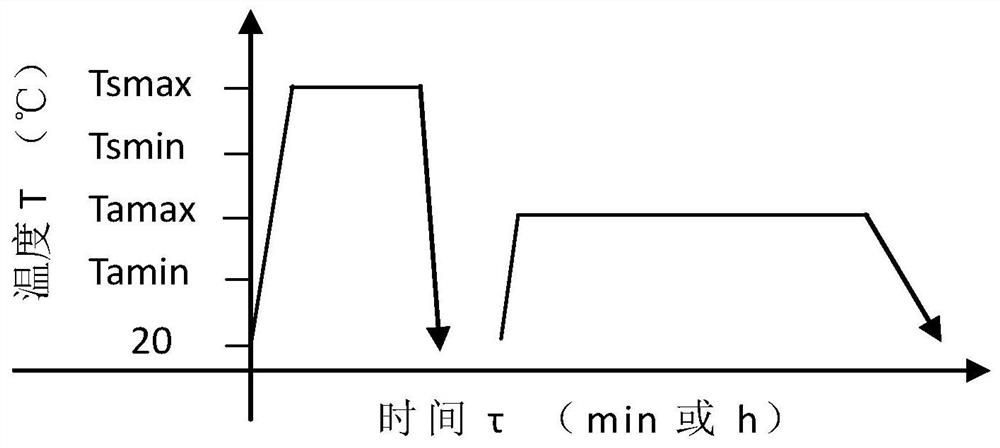

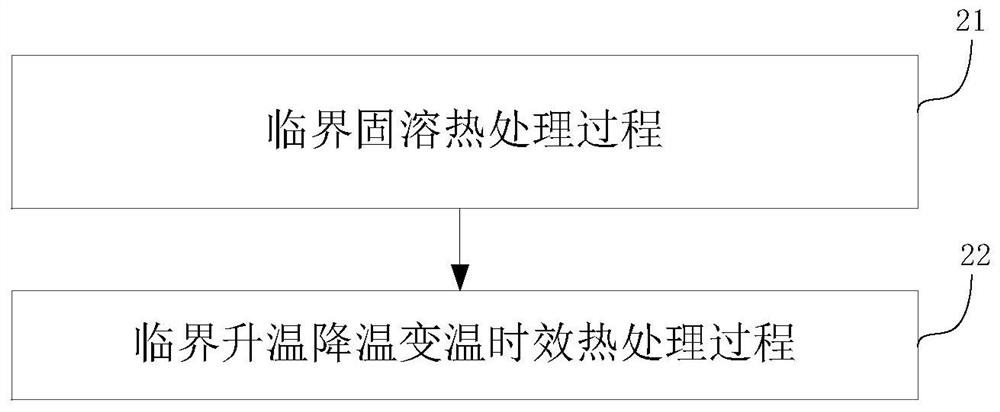

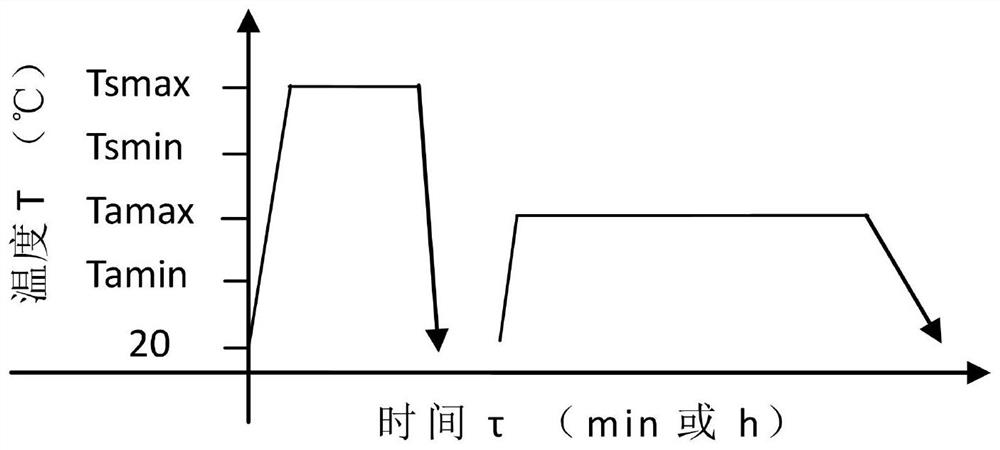

The invention provides a critical solid solution and critical cooling and heating variable-temperature aging and annealing heat treatment method. The critical solid solution and critical cooling and heating variable-temperature aging and annealing heat treatment method comprises a critical solid solution heat treatment process and a critical cooling and heating variable-temperature aging and annealing heat treatment process. According to the scheme, the method has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, the advantages can be effectively adopted, disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel are avoided, the special heat treatment problems of poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, poor discoloration and corrosion resistance, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature parts, high cost and the like of austenitic stainless steel heat treatment are solved, the method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel involved in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

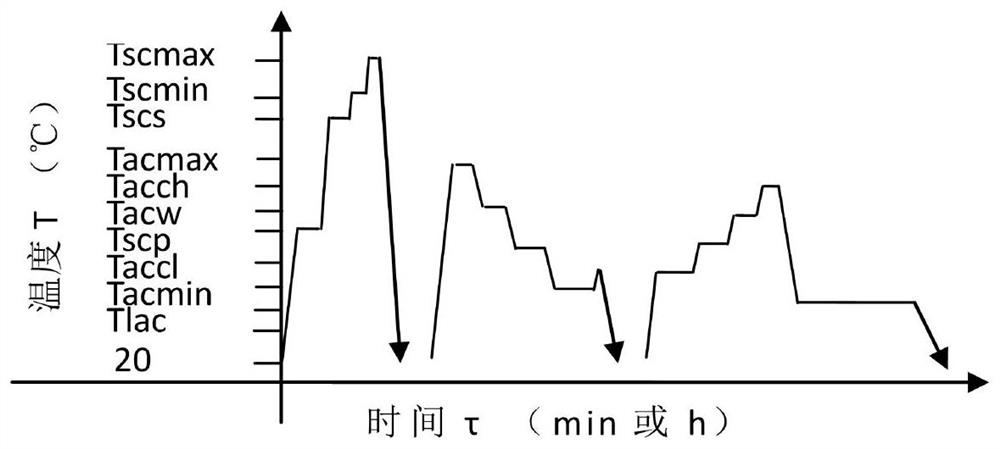

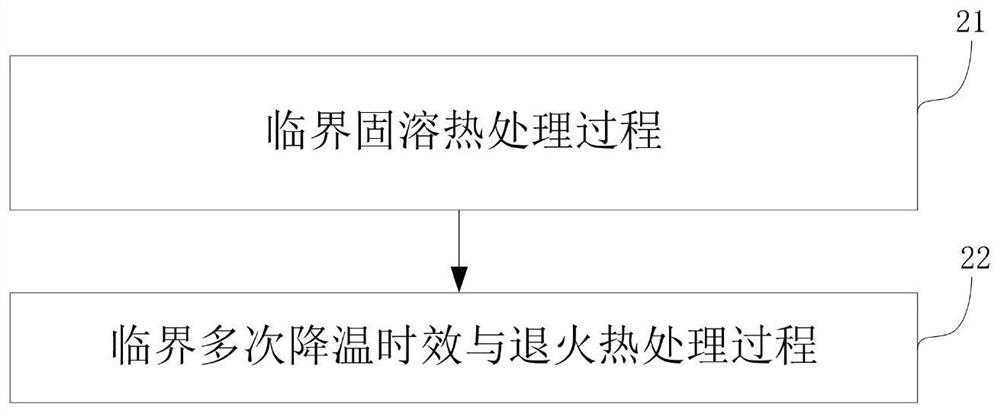

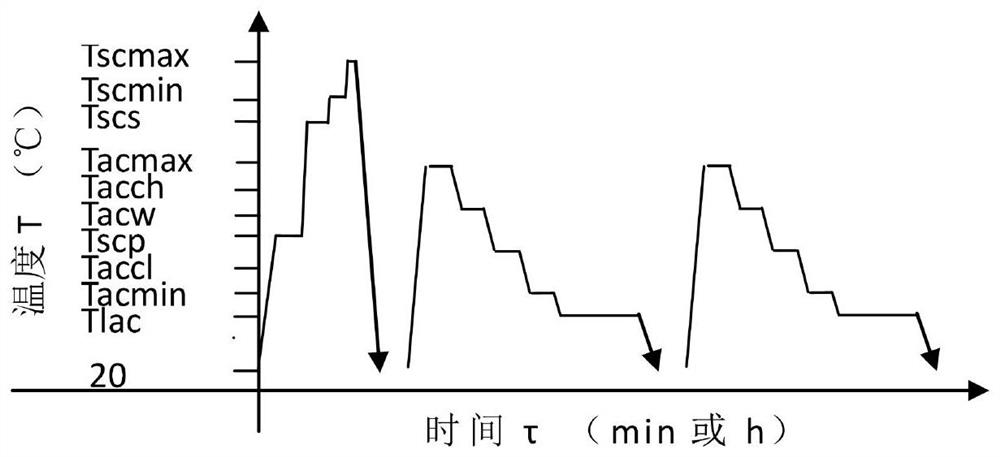

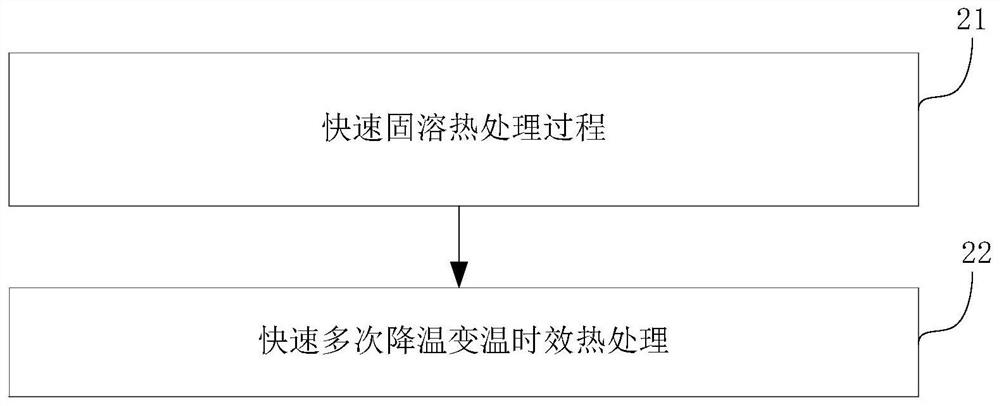

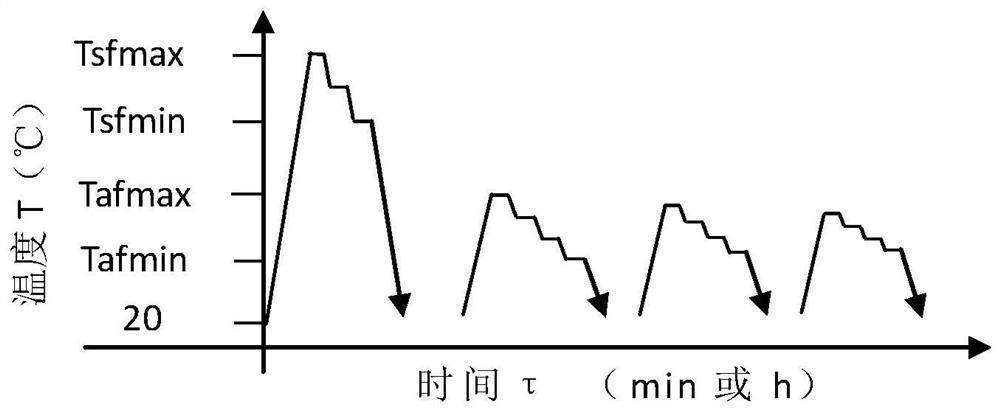

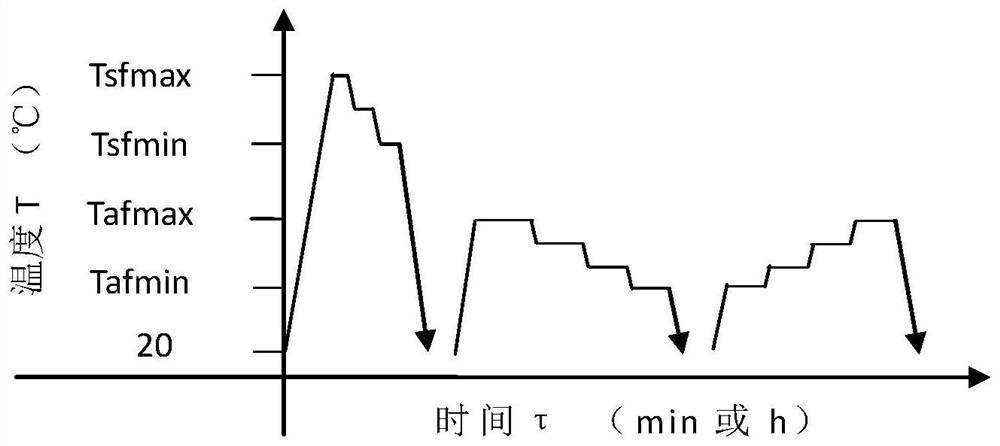

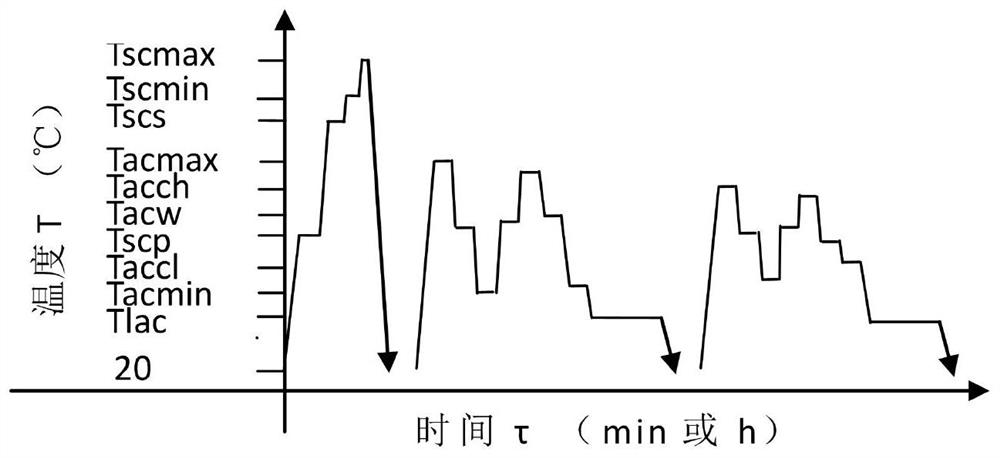

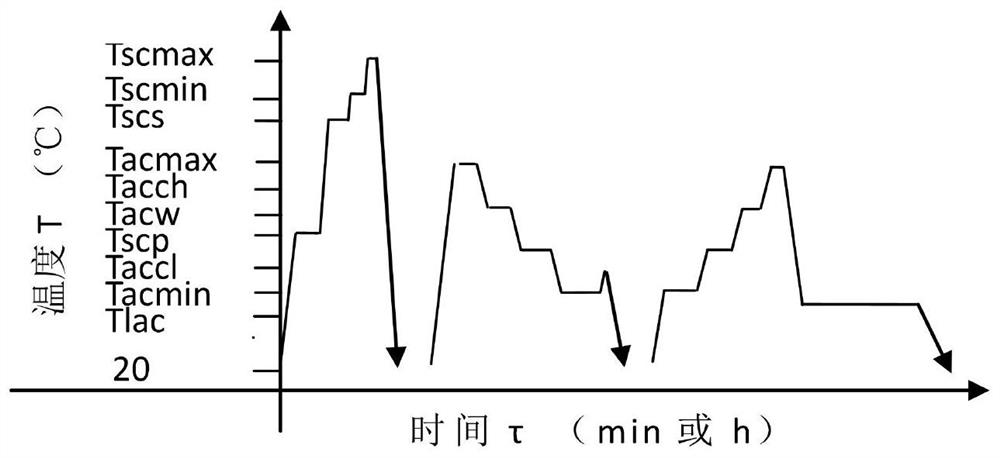

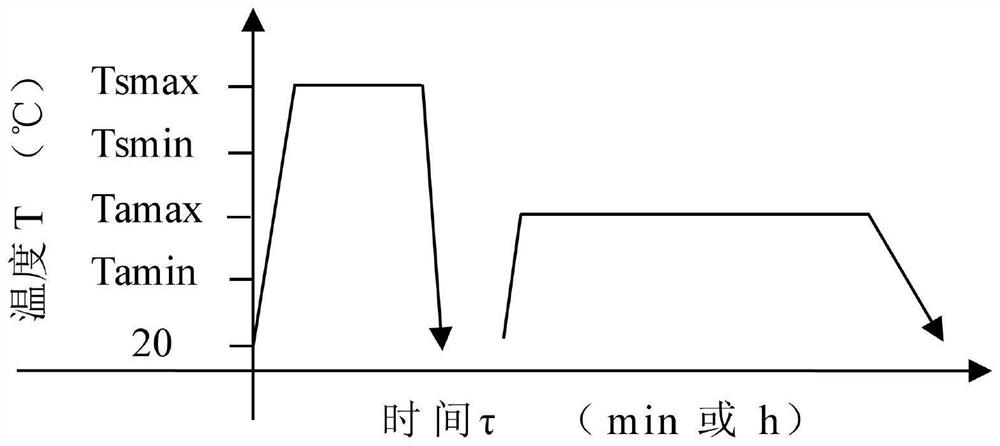

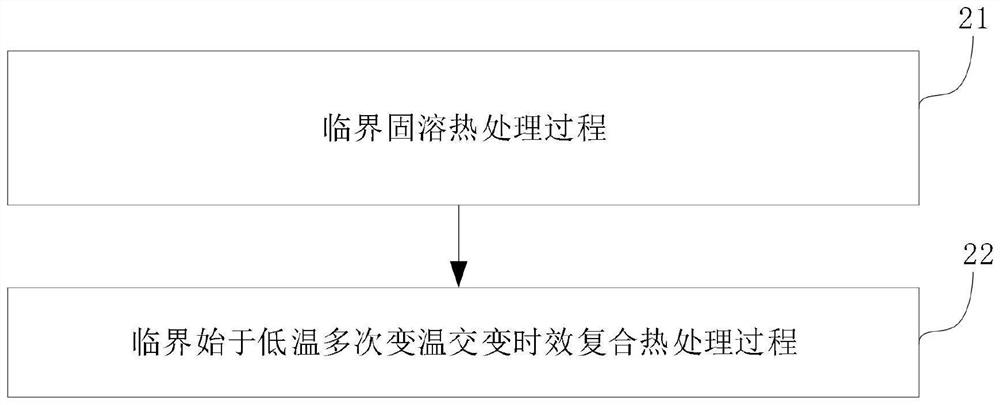

Critical solid solution and critical multiple cooling variable temperature aging and annealing composite heat treatment method

PendingCN114395668ATechnically feasibleProcess adaptabilityHeat treatment process controlHeating timeAustenite

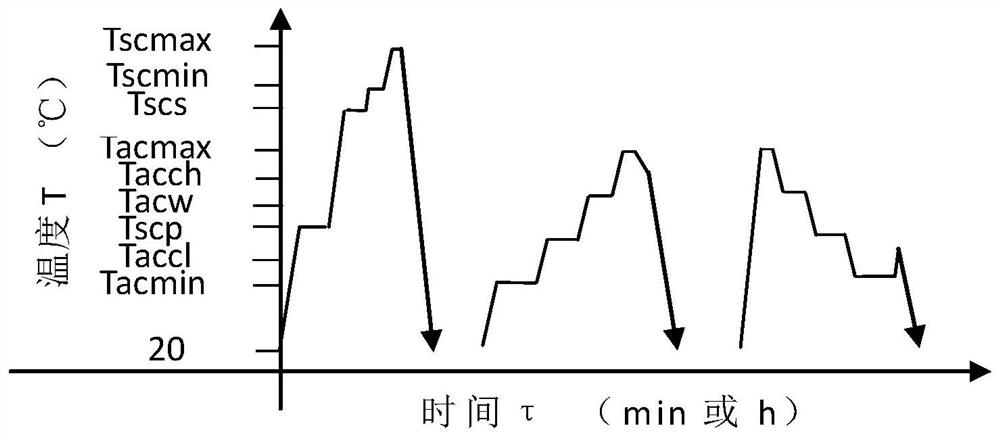

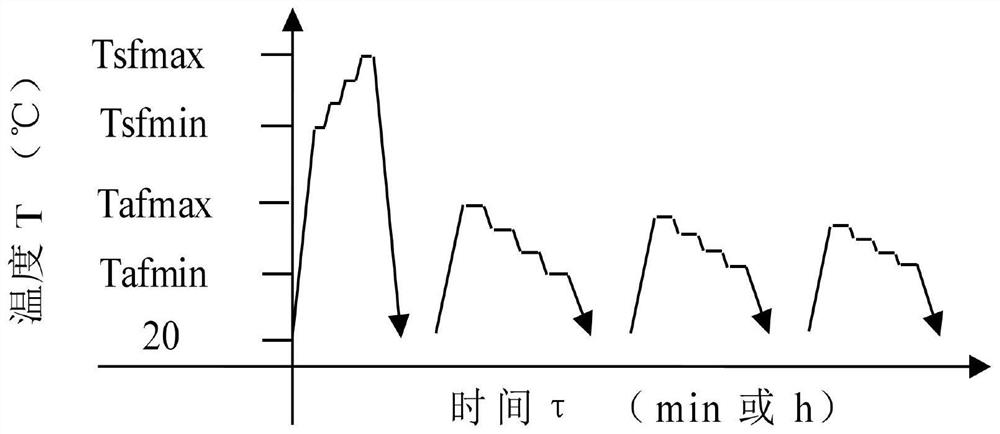

The invention provides a critical solid solution and critical multiple cooling variable temperature aging and annealing composite heat treatment method. The method comprises a critical solid solution heat treatment process and a critical multiple-cooling variable-temperature aging and annealing composite heat treatment process. According to the scheme, the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like can be solved. The heating reliability of heat treatment equipment is poor; the service life of a high-temperature component is short; the cost is high; and the like.

Owner:山西柴油机工业有限责任公司

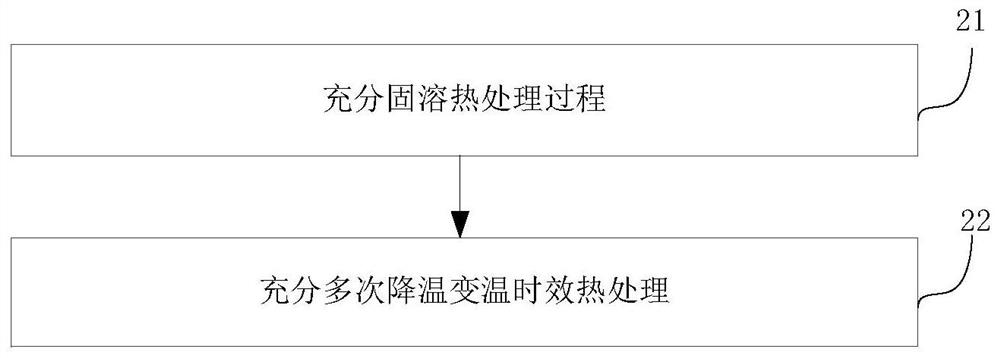

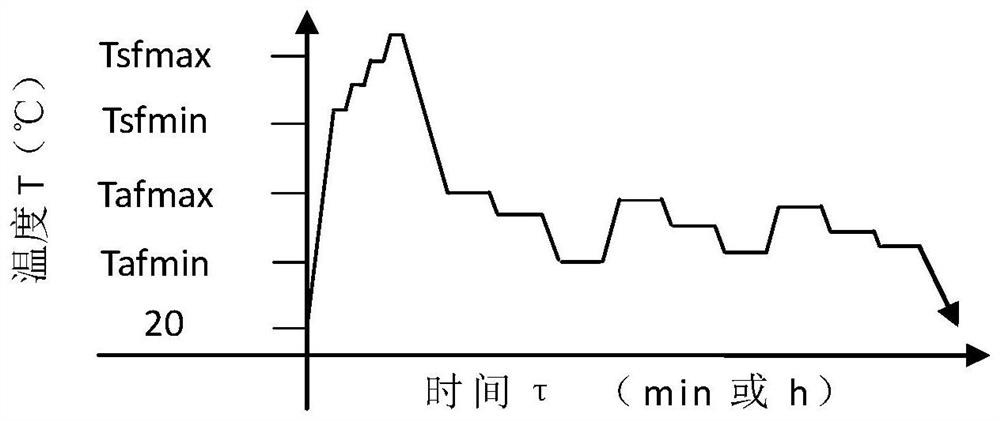

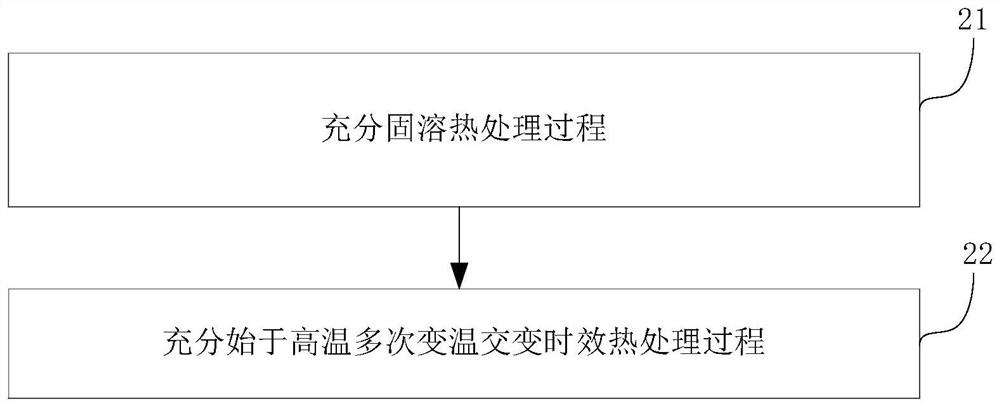

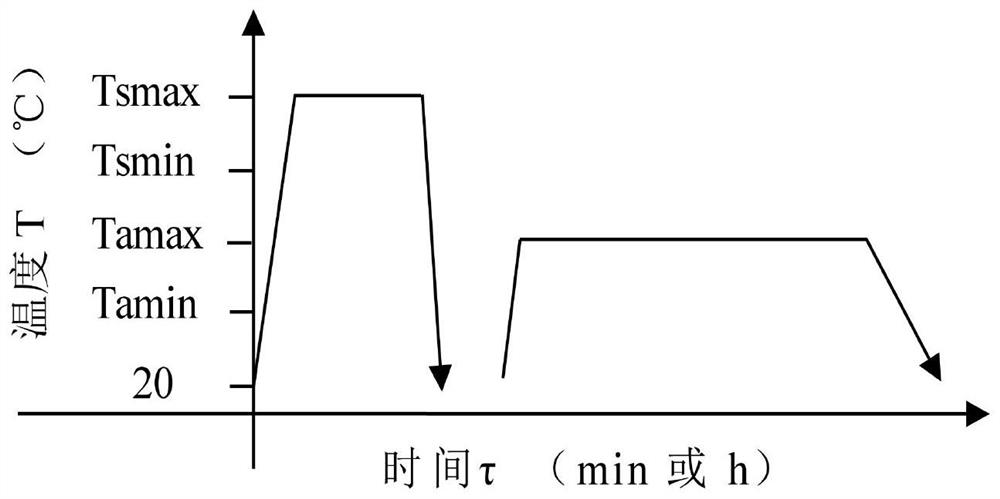

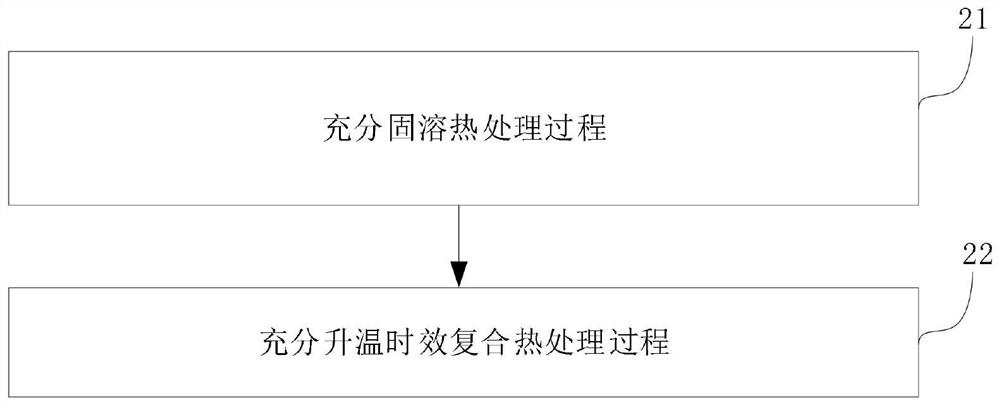

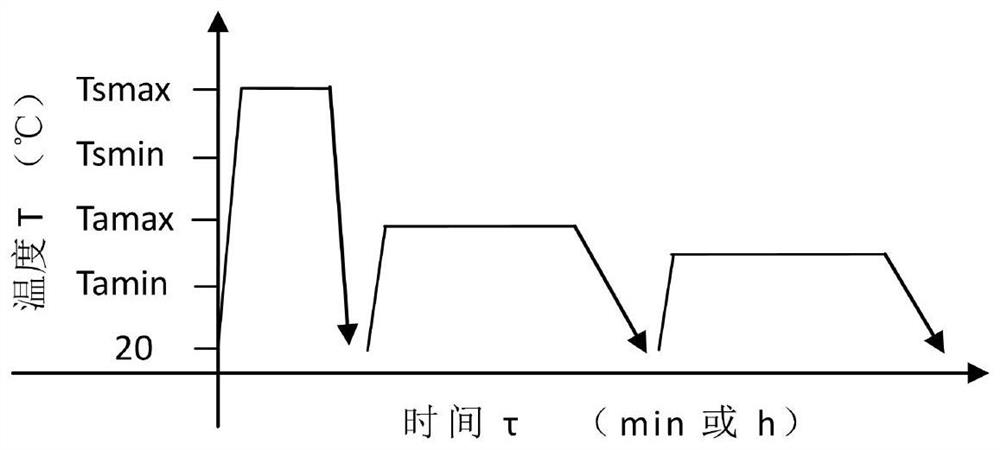

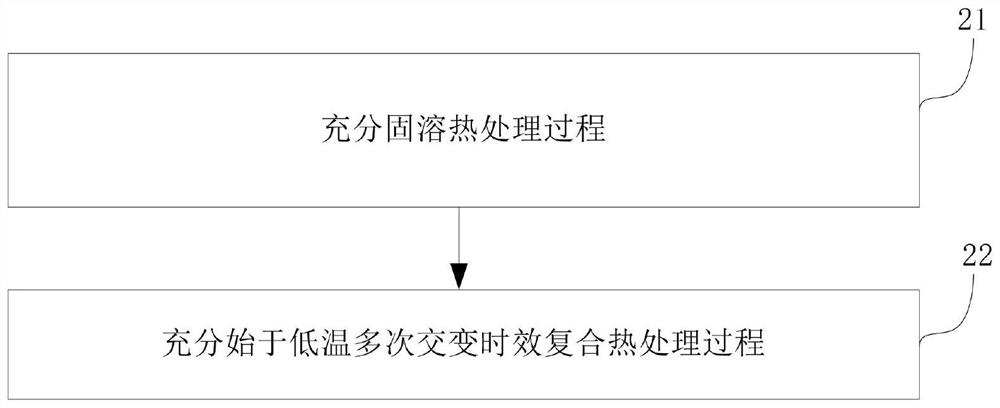

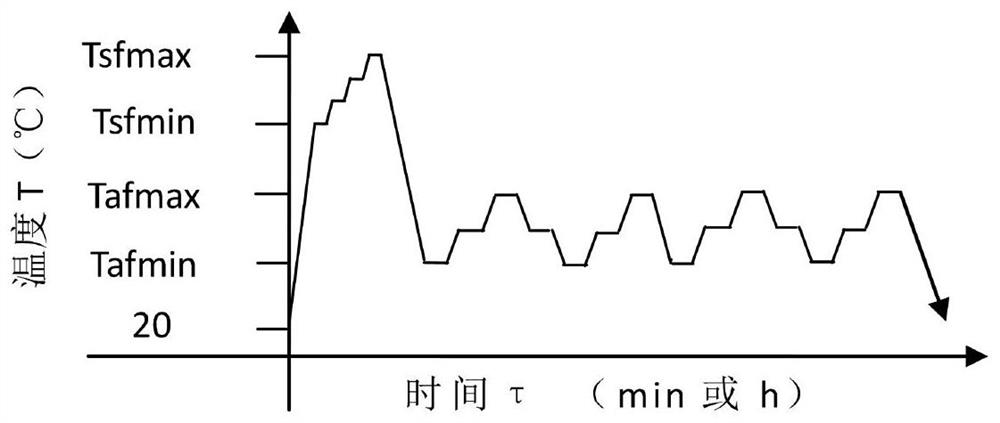

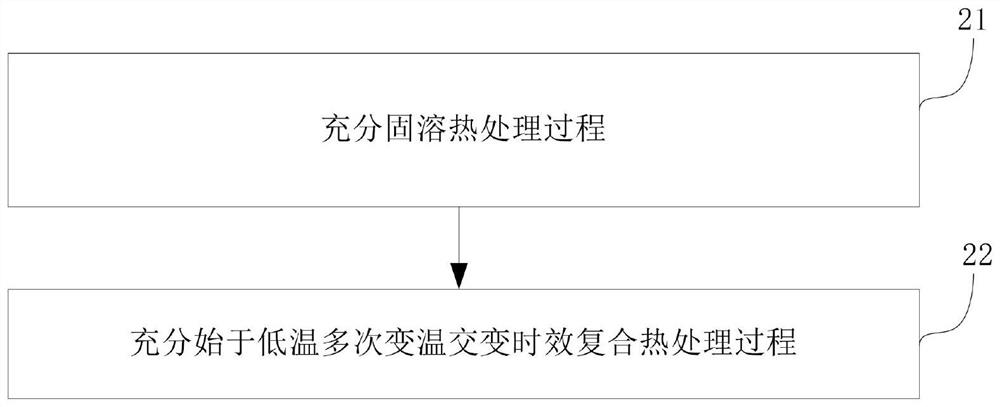

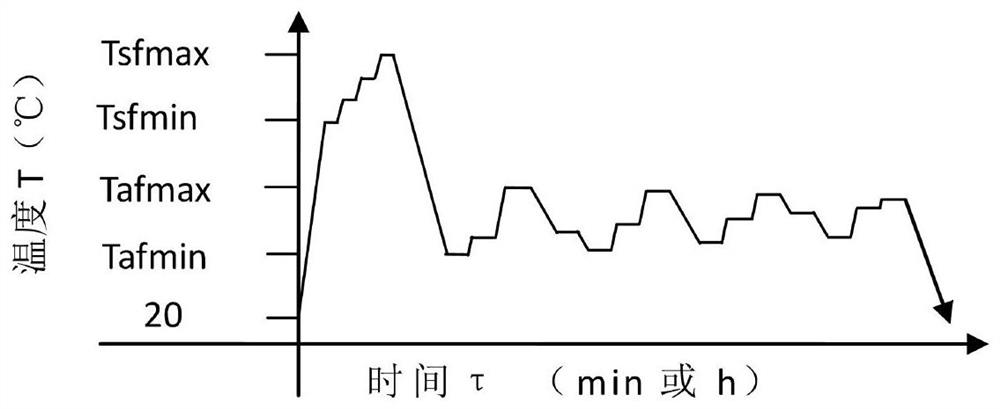

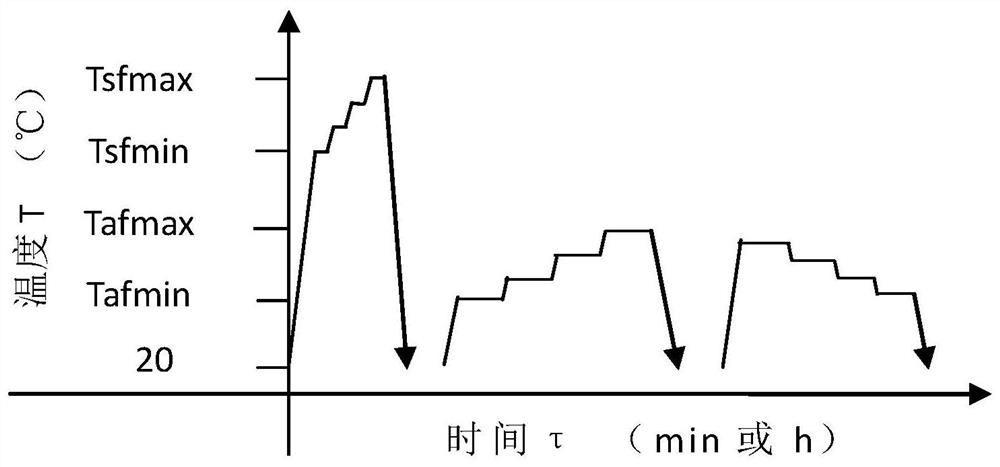

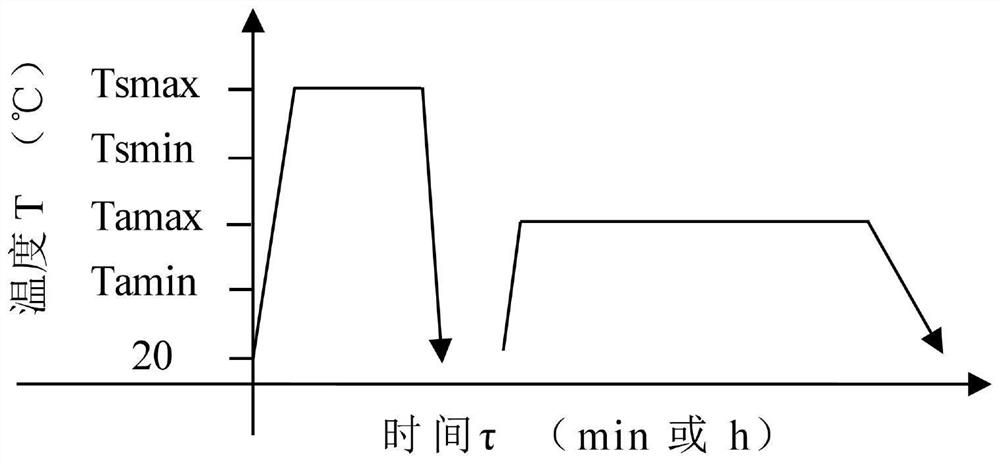

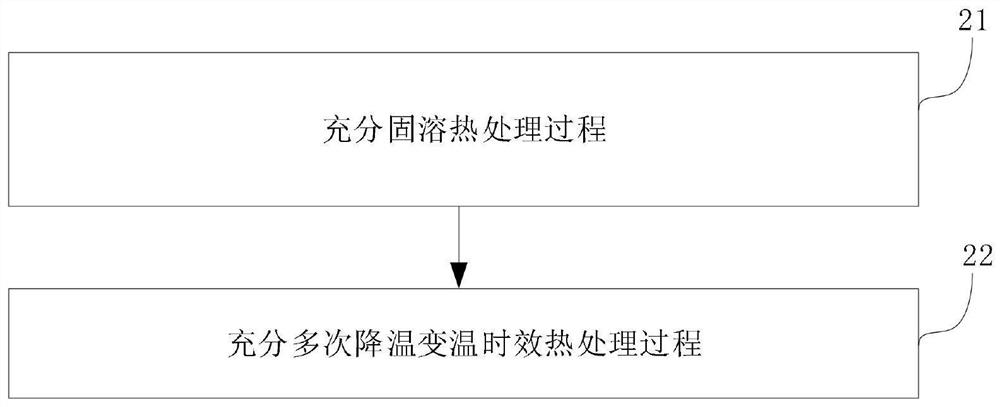

Sufficient solid solution and sufficient multi-time cooling variable-temperature aging composite heat treatment method

The invention provides a sufficient solid solution and sufficient multi-time cooling variable-temperature aging composite heat treatment method. The method comprises a sufficient solid solution heat treatment process and a sufficient multi-time cooling variable-temperature aging heat treatment process. According to the scheme, the problems that mainstream austenitic stainless steel solid solution and aging heat treatment are poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

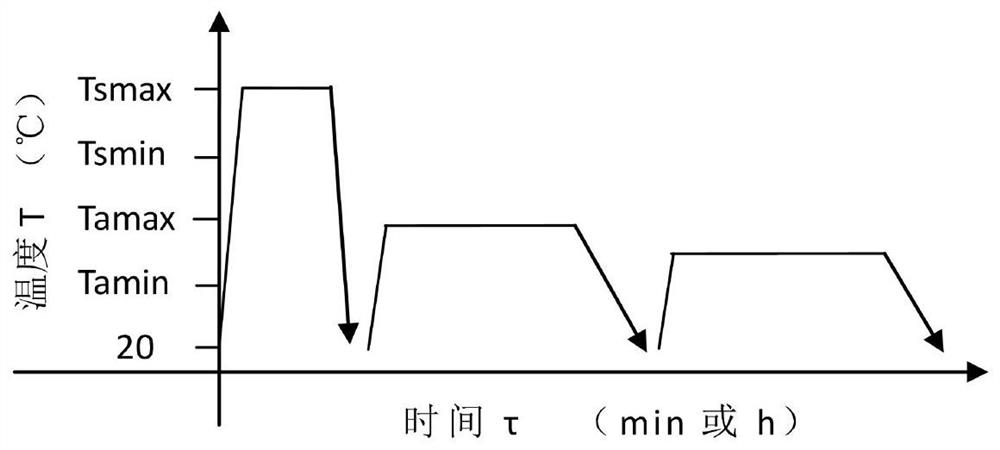

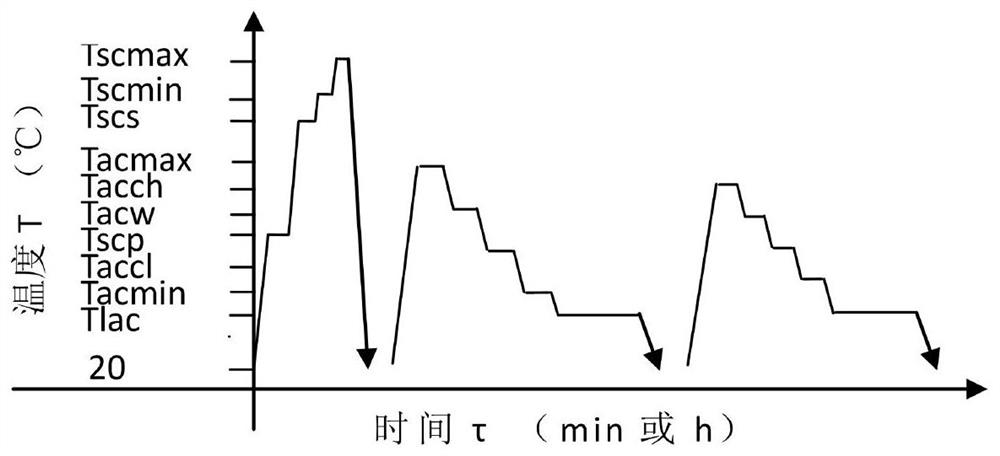

Critical solid solution and critical repeated cooling aging and annealing heat treatment method

The invention provides a critical solid solution and critical repeated cooling aging and annealing heat treatment method which comprises a critical solid solution heat treatment process and a critical repeated cooling aging and annealing heat treatment process. The scheme of the invention has technical feasibility, process adaptability, quality reliability, economic reasonability and use safety, can effectively enhance the advantages and avoid the disadvantages of a conventional mainstream heat treatment method of austenitic stainless steel, fundamentally solves the "one-long one-high four-poor five-low" special heat treatment technical difficult problems of "poor quality stability, low rate of qualified products, low hardness, low mechanical property, poor consistency, poor discoloration and rust corrosion resistance, long heating time, low efficiency, poor heating reliability of heat treatment equipment and low service life and high cost of a high-temperature component" of existing austenitic stainless steel heat treatment, and is particularly suitable for the technical field of heat working engineering such as smelting, steel rolling, forging, heat treatment and the like related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

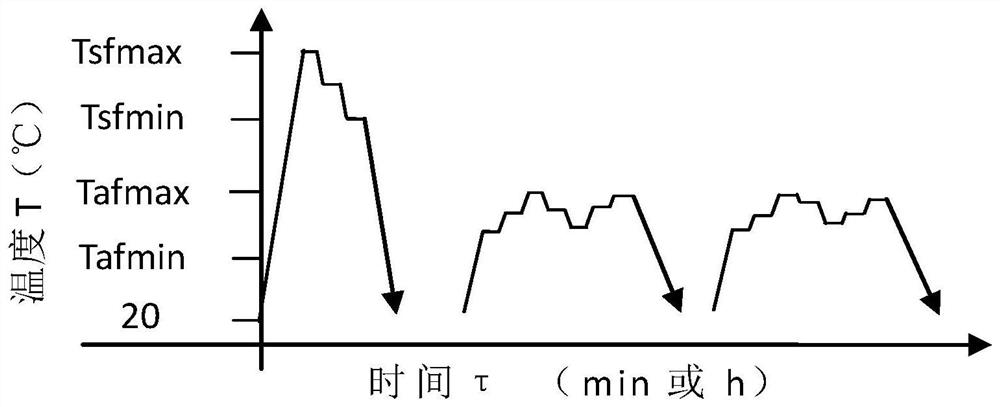

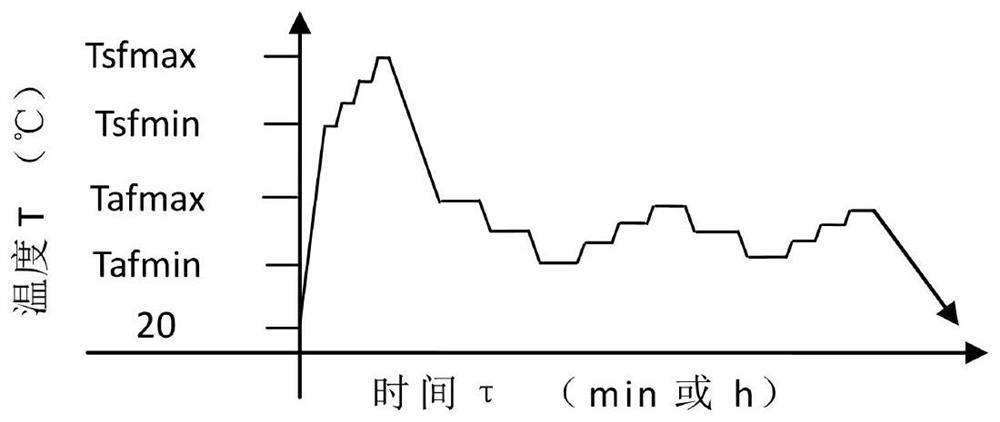

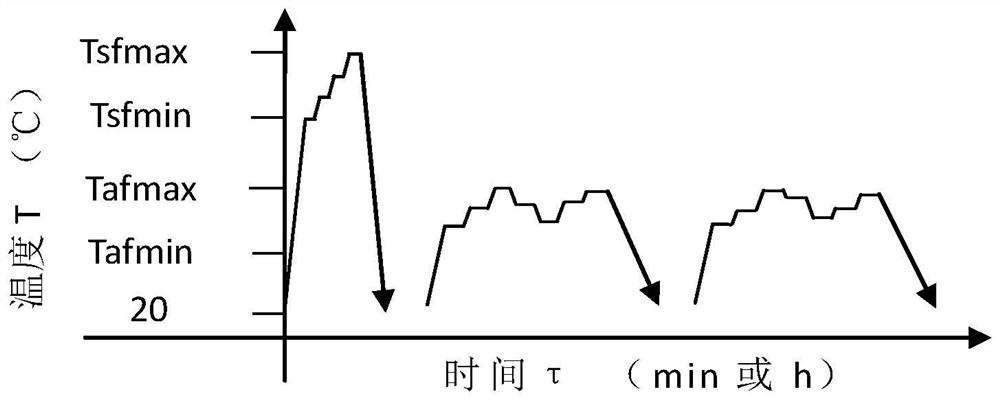

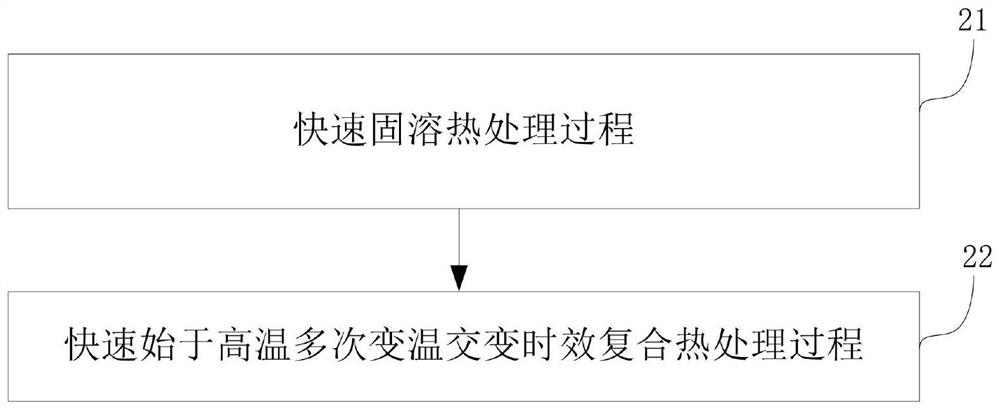

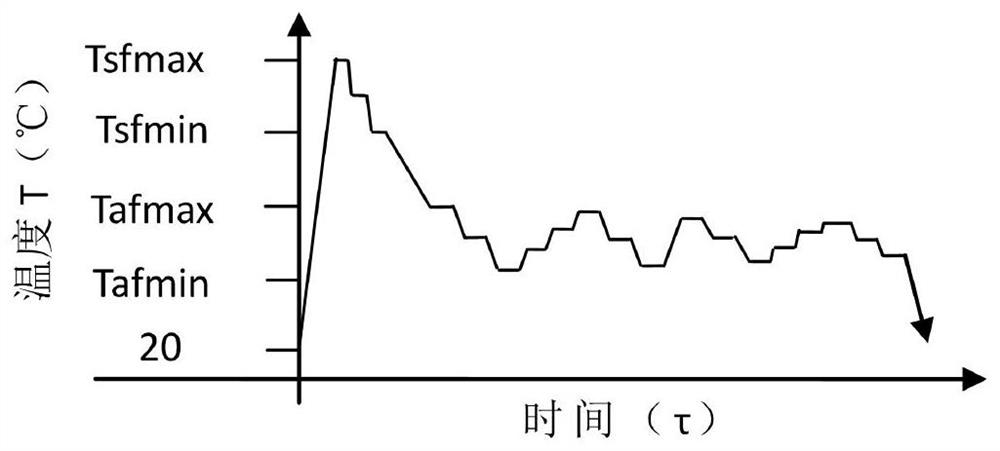

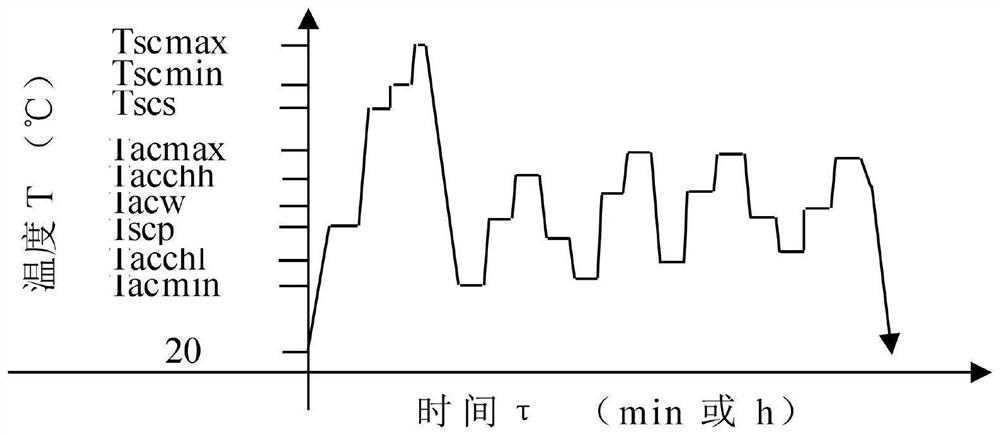

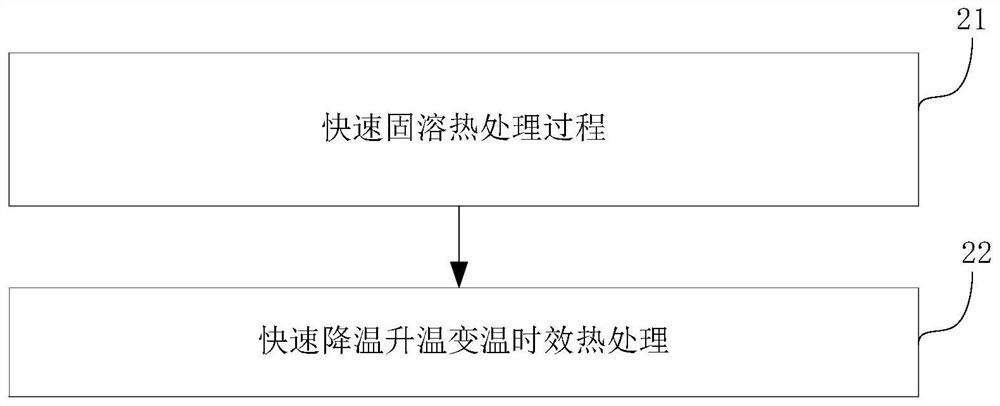

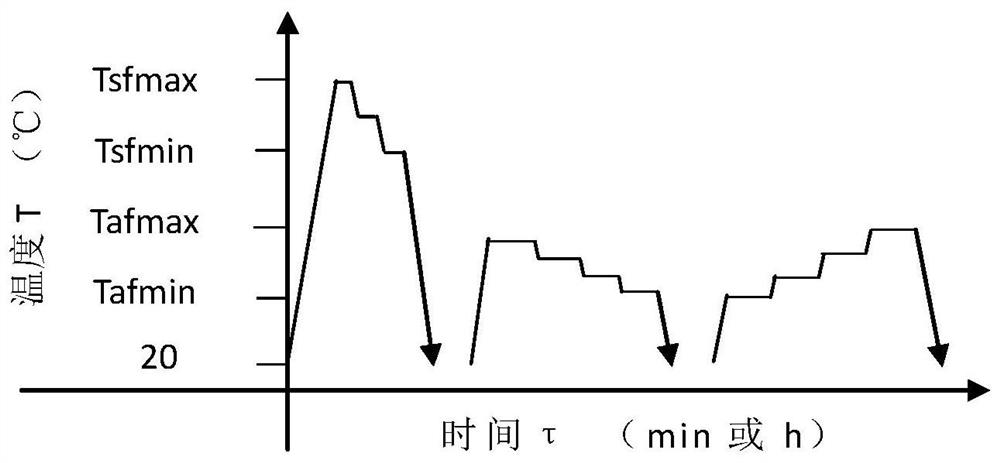

Rapid solid solution and rapid starting from high-temperature multi-time variable-temperature alternating aging heat treatment method

The invention provides a rapid solid solution and rapid starting from high-temperature multi-time variable-temperature alternating aging heat treatment method. The heat treatment method comprises a rapid solid solution heat treatment process and a rapid starting from high-temperature multi-time variable-temperature alternating aging heat treatment process. According to the scheme, the problems that mainstream austenitic stainless steel solid solution and aging heat treatment are poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency, heat treatment equipment is poor in heating reliability, components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

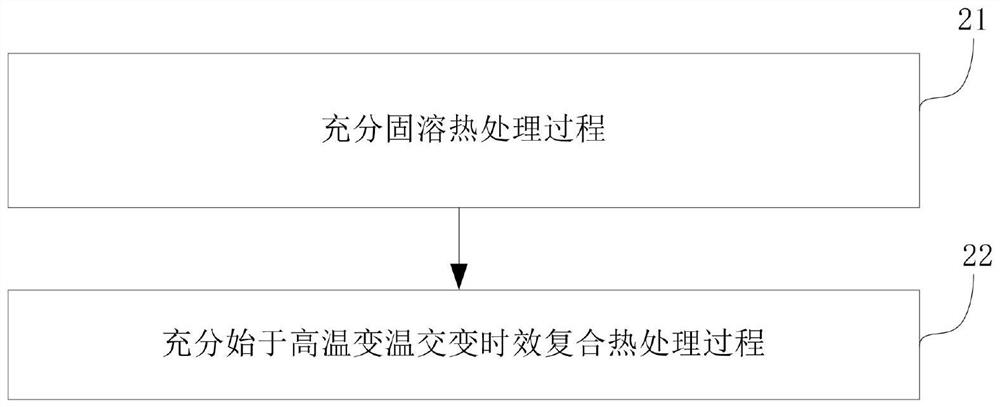

Complex heat treatment method for full solid solution and full high-temperature-starting variable-temperature alternating aging

PendingCN114395686AQuality and reliabilityTechnically feasibleHeat treatment process controlThermodynamicsHeating time

The invention provides a composite heat treatment method fully starting from high-temperature variable-temperature alternating aging. The composite heat treatment method fully starting from high-temperature variable-temperature alternating aging comprises a full solid solution heat treatment process and a composite heat treatment process fully starting from high-temperature variable-temperature alternating aging. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

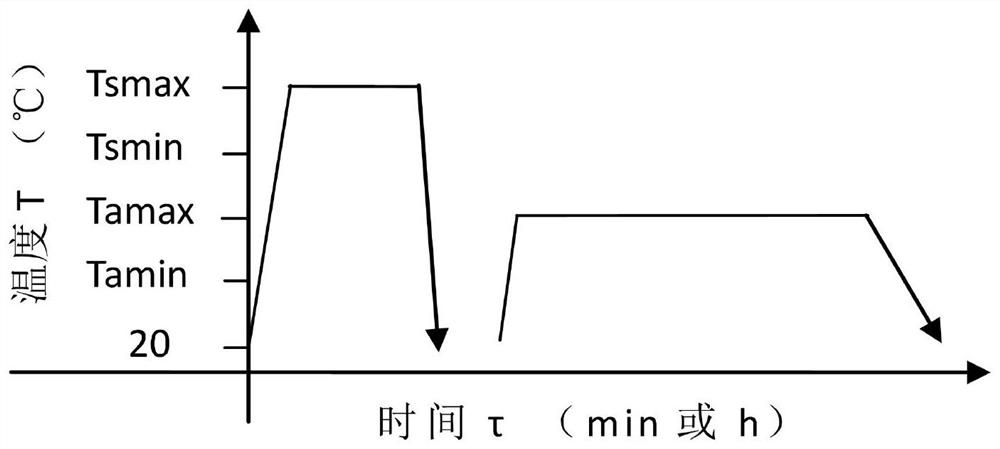

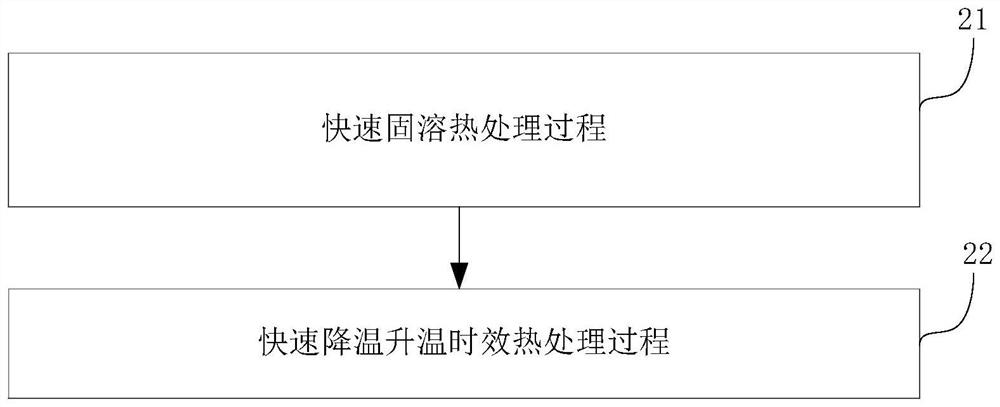

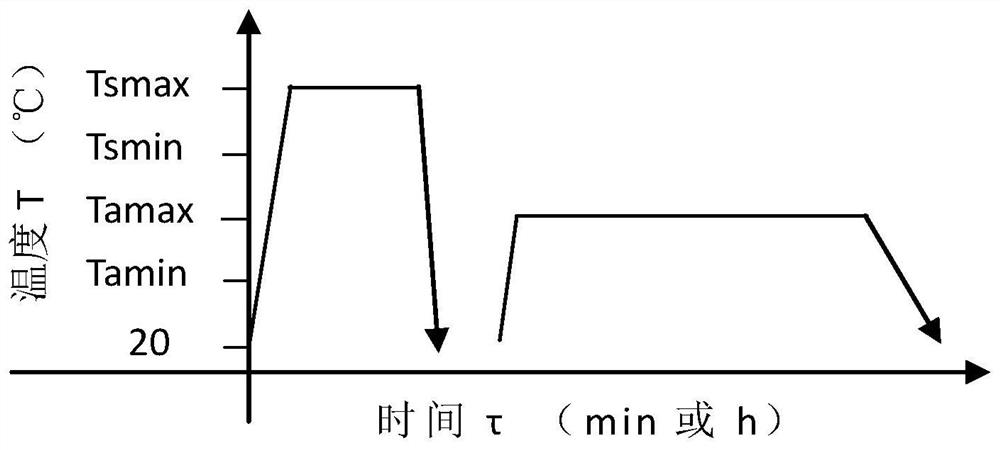

Rapid solid solution and rapid multi-cooling variable-temperature aging heat treatment method

PendingCN112725591AQuality and reliabilityImprove quality stabilityThermodynamicsProcess engineering

The invention provides a rapid solid solution and rapid multi-cooling variable-temperature aging heat treatment method. The rapid solid solution and rapid multi-cooling variable-temperature aging heat treatment method involves a rapid solid solution heat treatment process and a rapid multi-cooling variable-temperature aging heat treatment process. According to the scheme, the special heat treatment technical problems of "one long, one high, three poor and five low", namely, poor quality stability, low qualified product rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature components, high cost and the like of austenitic stainless steel heat treatment can be solved.

Owner:山西柴油机工业有限责任公司

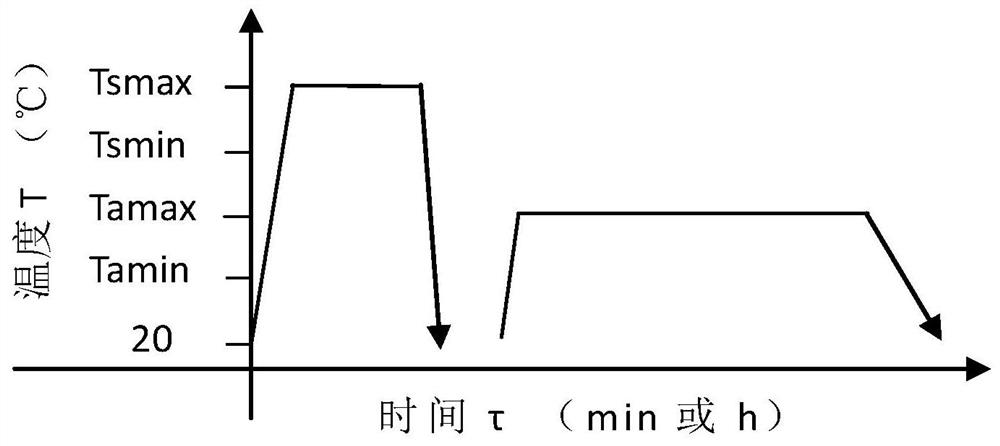

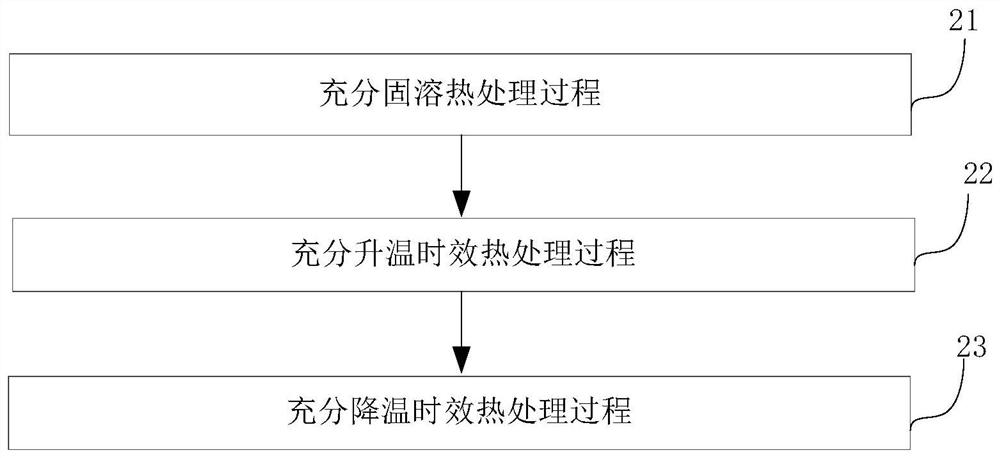

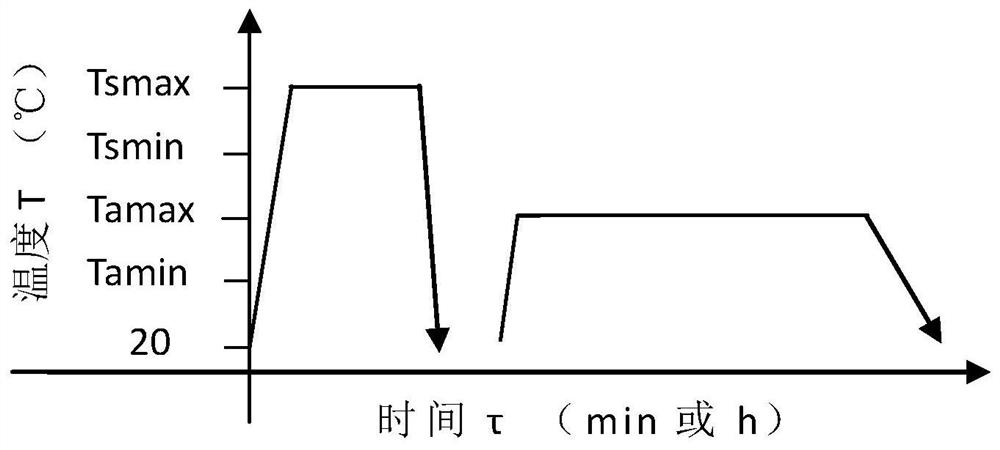

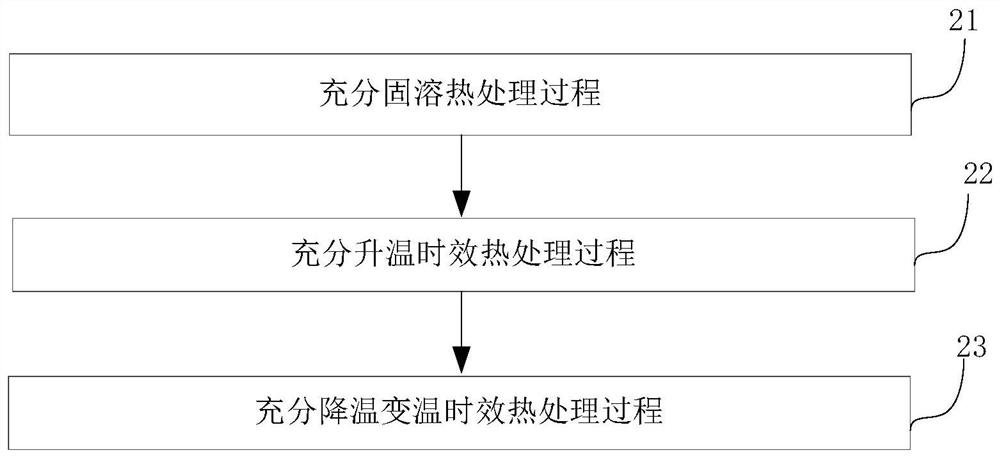

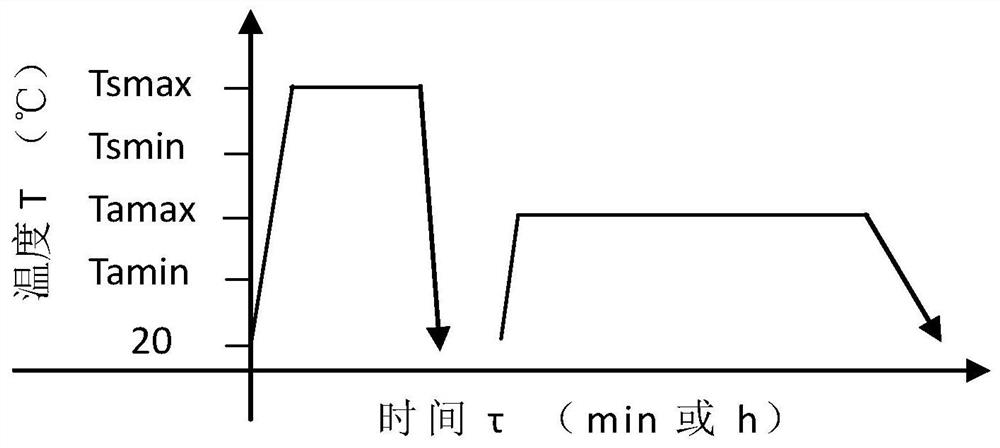

Aging heat treatment method with sufficient solid solution and sufficient heating and cooling

The invention provides an aging heat treatment method with sufficient solid solution and sufficient heating and cooling. The method comprises a sufficient solid solution heat treatment process, a sufficient heating aging heat treatment process and a sufficient cooling aging heat treatment process. According to the scheme, the special heat treatment technical problems of poor quality stability, low qualified product rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature parts, high cost and the like of existing austenitic stainless steel heat treatment can be solved.

Owner:山西柴油机工业有限责任公司

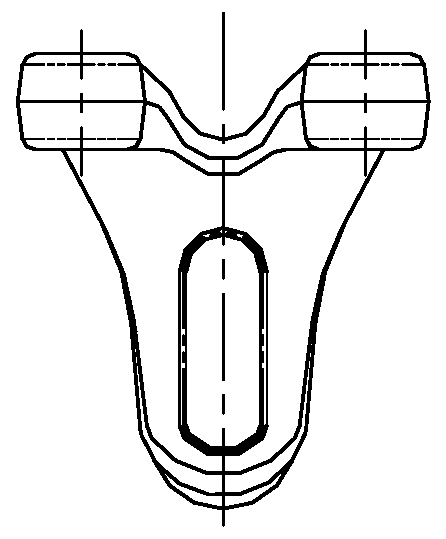

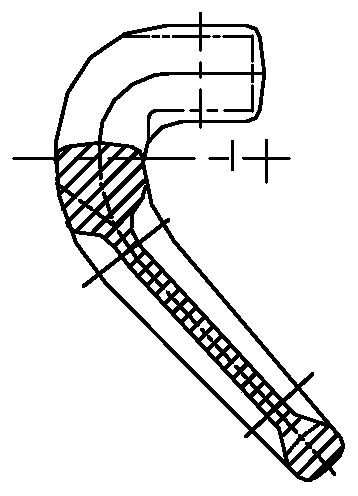

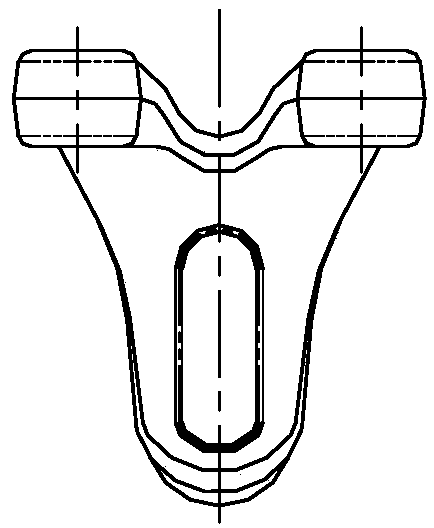

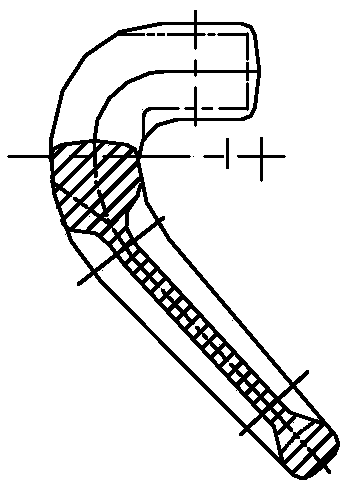

A forging die formed by combined die forging

ActiveCN107855453BExtended service lifeTechnically feasibleForging/hammering/pressing machinesHooksMaterials scienceTechnical feasibility

The invention discloses a hot straightening forging die and a hot bending forging die for combined die forging formation. The hot straightening forging die comprises a drawing and flattening blankingimpression, a diagonal-form lock catch, a pre-forging impression, a pre-forging flash gutter, a final-forging impression and a final-forging flash gutter, and is used for obtaining hook straight semi-finished die forgings not completely meeting the final shape and dimension requirements. The hot bending forging die comprises a pre-bending impression, a final-bending impression and a single-longitudinal dual-corner combined lock catch and is used for obtaining hook die forged pieces thoroughly meeting the shape and dimension requirements. The hot straightening forging die and the hot bending forging die for combined die forging formation have the technical feasibility, quality reliability, economic rationality and using safety, and the problems of poor reliability, low form and location tolerance and dimension tolerance precision, low quality rate, high deformation force, low efficiency, short service life of the forging dies and the like of an existing combined die forging formation method including blanking on a 10-kN free forging hammer, die forging on a 20-kN die forging hammer and bending on a 3150-kN trimming press are effectively solved.

Owner:STATE RUN NO 616 FACTORY

A combined precision die forging forming method

The invention discloses a combined precision die forging formation method. The combined precision die forging formation method comprises primary hot straight die forging formation and secondary hot bending die forging formation. Lifting hook straight semi-finished product die forged parts which do not meet the final shape and dimension requirements completely are obtained through a hot straight die forging technology and a hot straight forging die; and the shape and dimension requirements of the lifting hook die forged parts are completely met ultimately through a hot bending die forging formation method and a hot bending forging die. By means of the combined precision die forging formation method, the problems that an existing lifting hook combined die forging formation method for 'blankmaking on a flat die hammer of 10kN, die forging on a forging hammer of 20kN and bending on a trimming pressure machine of 3150kN' is poor in reliability, low in form and location tolerance and dimensional tolerance precision, low in qualified product rate, large in deformation force, low in forging efficiency and short in die forging service life, and the number of forged parts produced by each set of die is less than four thousands are effectively solved.

Owner:STATE RUN NO 616 FACTORY

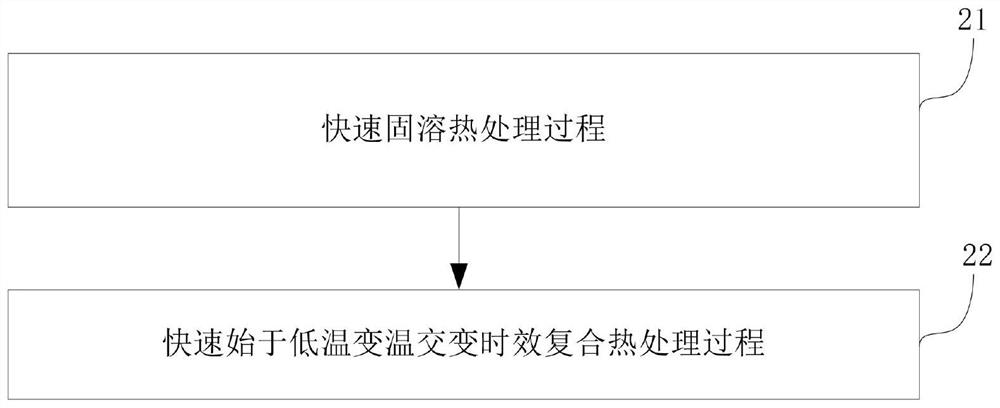

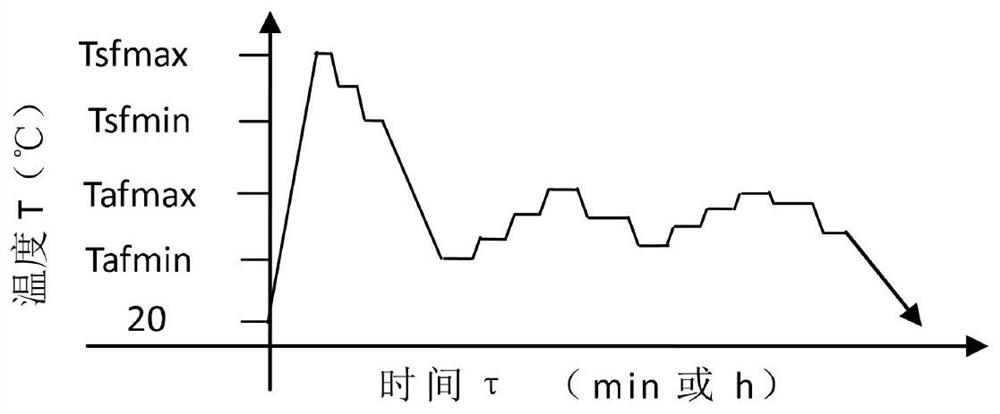

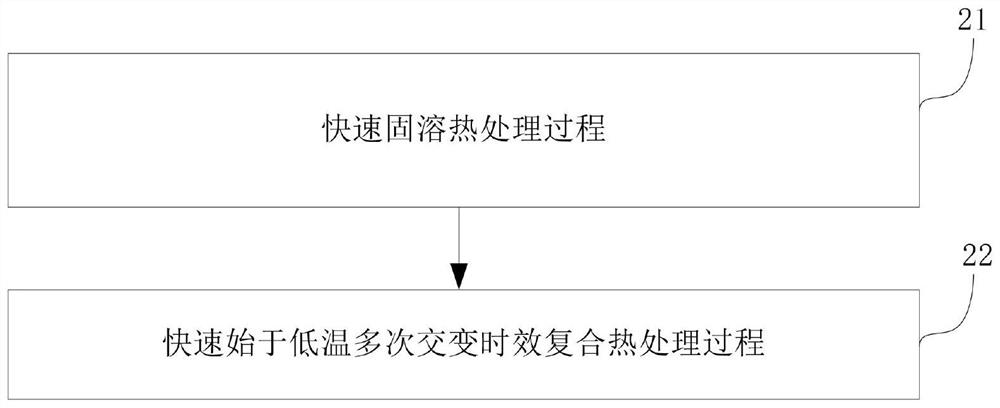

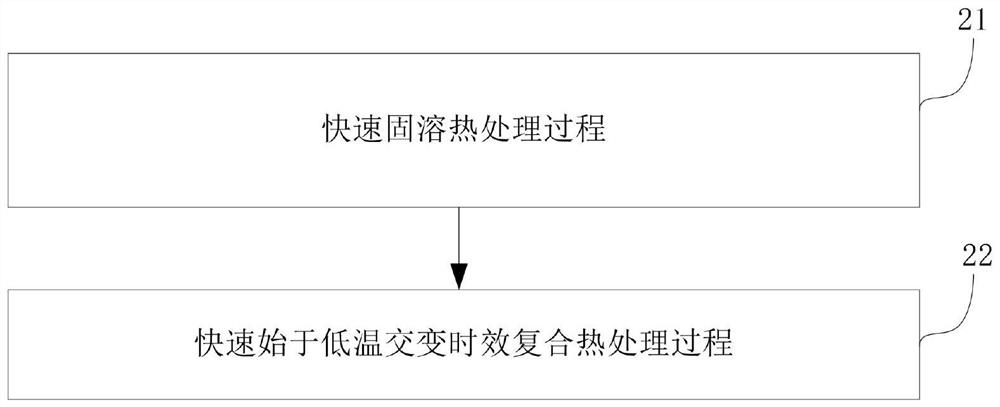

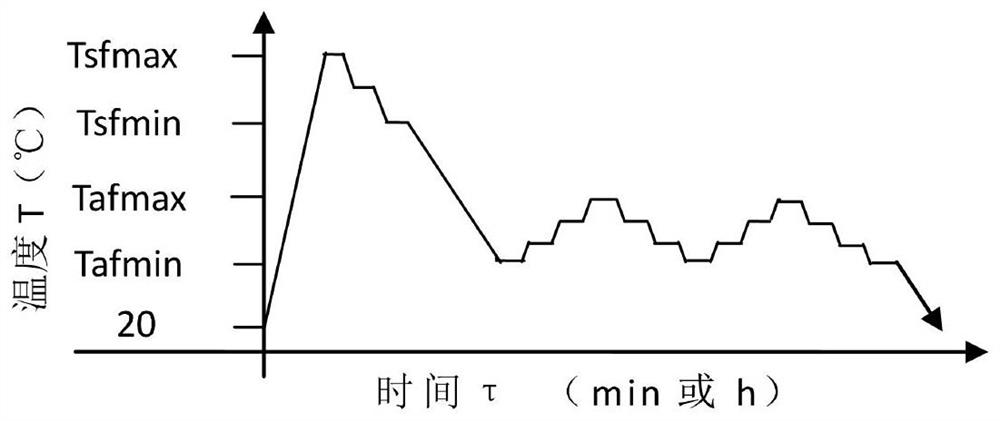

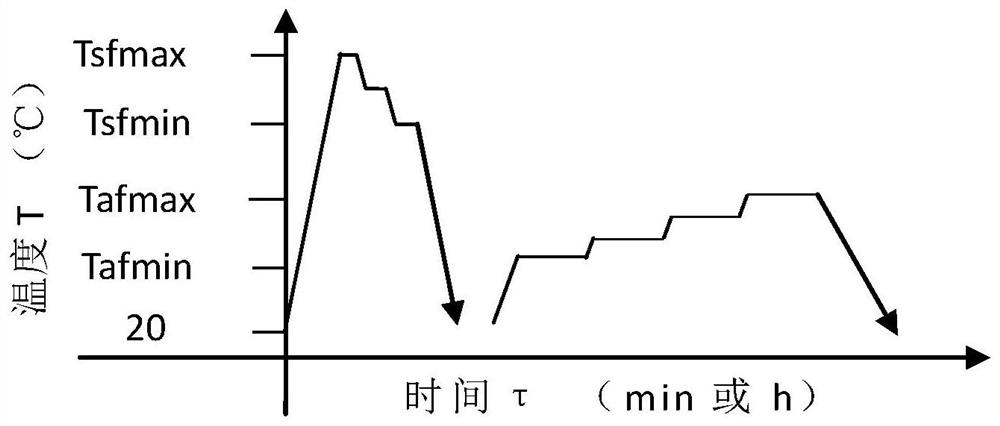

Composite heat treatment method for rapid solid solution and rapid starting from low-temperature variable-temperature alternating aging

The invention provides a composite heat treatment method for rapid solid solution and rapid starting from low-temperature variable-temperature alternating aging. The composite heat treatment method comprises a rapid solid solution heat treatment process and a composite heat treatment process for rapid starting from low-temperature variable-temperature alternating aging. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

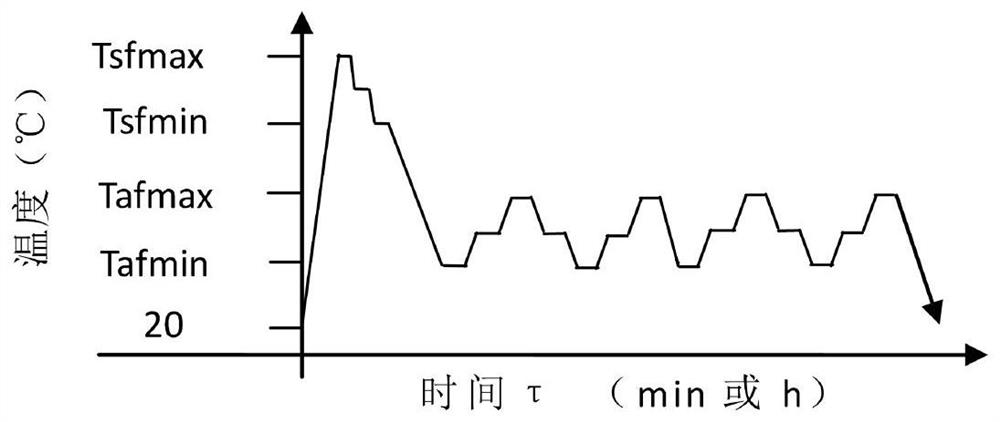

Rapid solid solution and rapid low-temperature multiple alternating aging composite heat treatment method

PendingCN114395684ATechnically feasibleProcess adaptabilityHeat treatment process controlHeating timeHardness

The invention provides a composite heat treatment method for rapid solid solution and rapid starting from low-temperature multiple alternating aging. The composite heat treatment method comprises a rapid solid solution heat treatment process and a composite heat treatment process for rapid starting from low-temperature multiple alternating aging. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

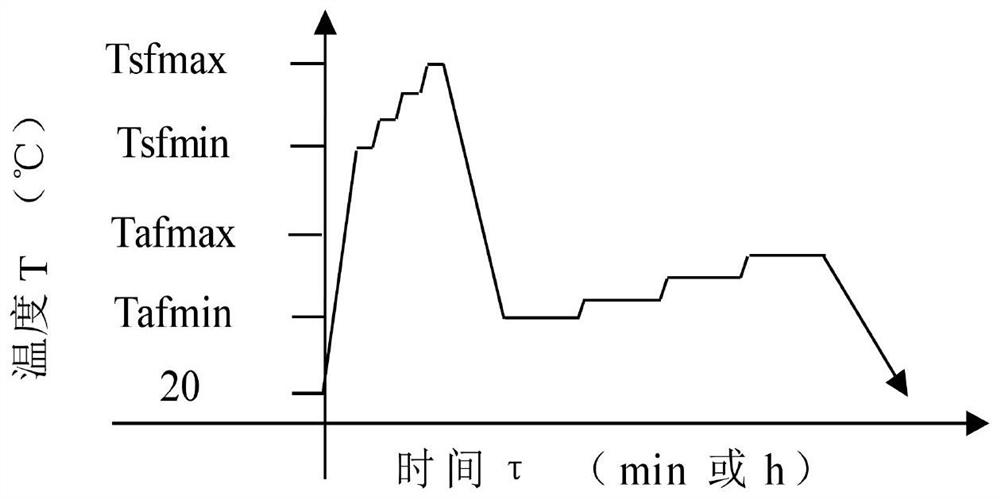

Heat treatment method capable of achieving sufficient solid solution and sufficiently starting from high-temperature multi-time variable-temperature alternating aging

The invention provides a heat treatment method capable of achieving sufficient solid solution and sufficiently starting from high-temperature multi-time variable-temperature alternating aging. The heat treatment method comprises a sufficient solid solution heat treatment process and a heat treatment process capable of sufficiently starting from high-temperature multi-time variable-temperature alternating aging. According to the scheme, the difficulties in theory and practice of special heat treatment technology that austenitic stainless steel is poor in solid solution and aging heat treatment quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, long in heating time and low in efficiency; and that heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, high in cost and the like can be solved.

Owner:山西柴油机工业有限责任公司

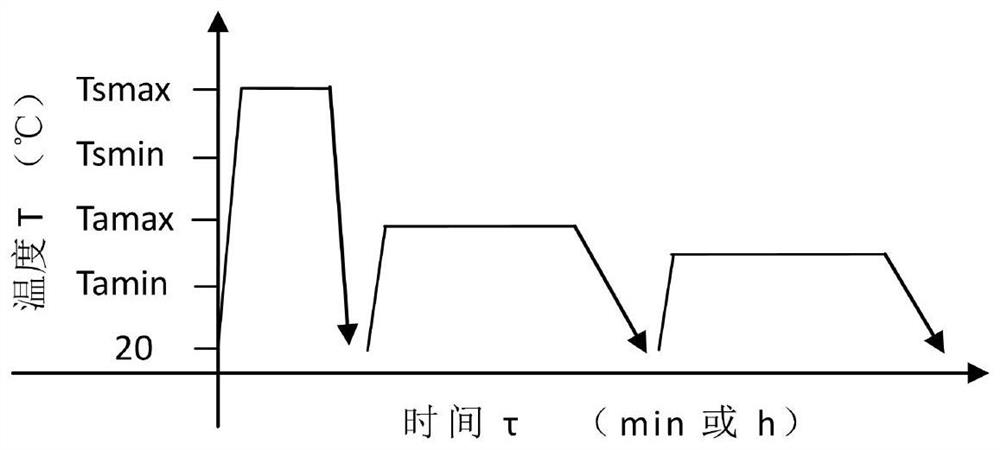

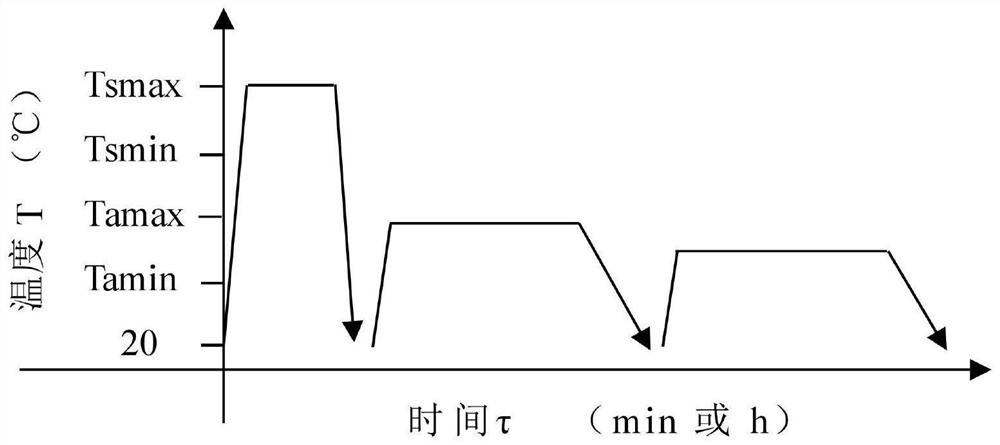

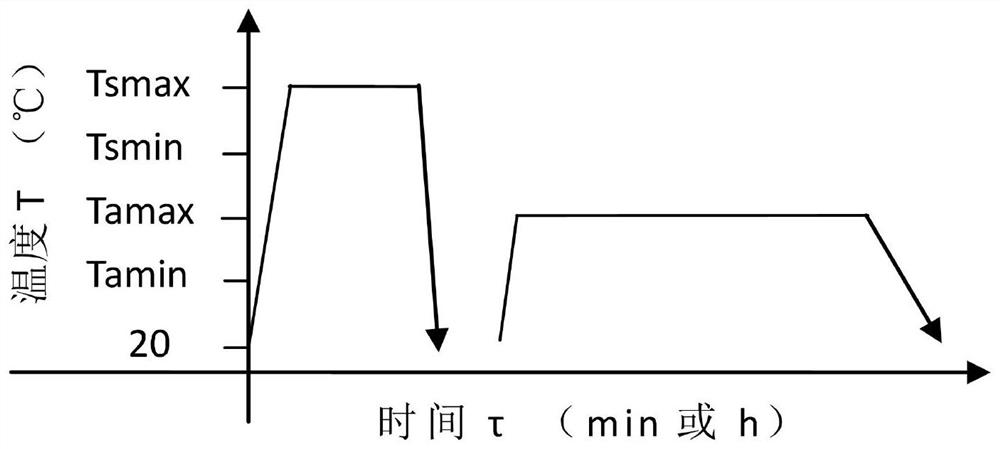

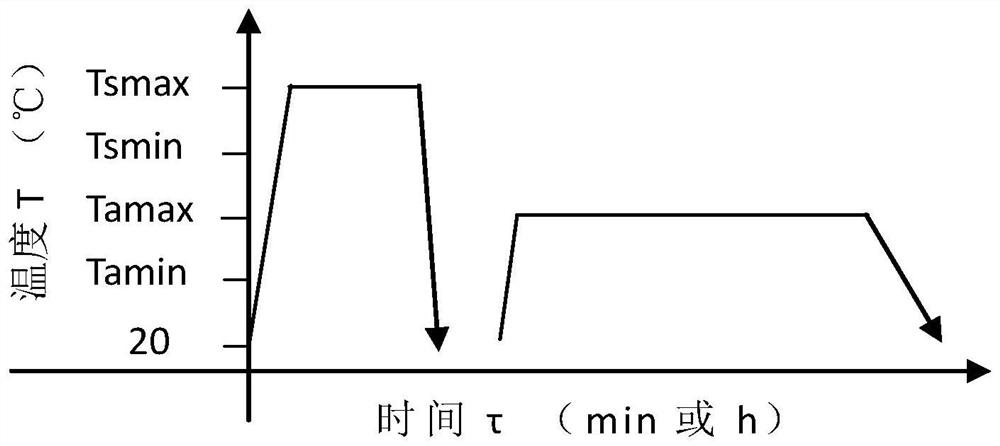

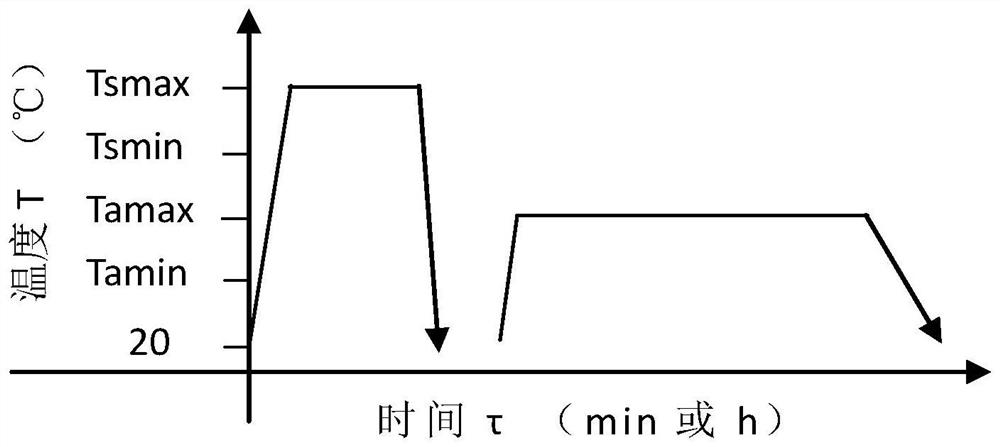

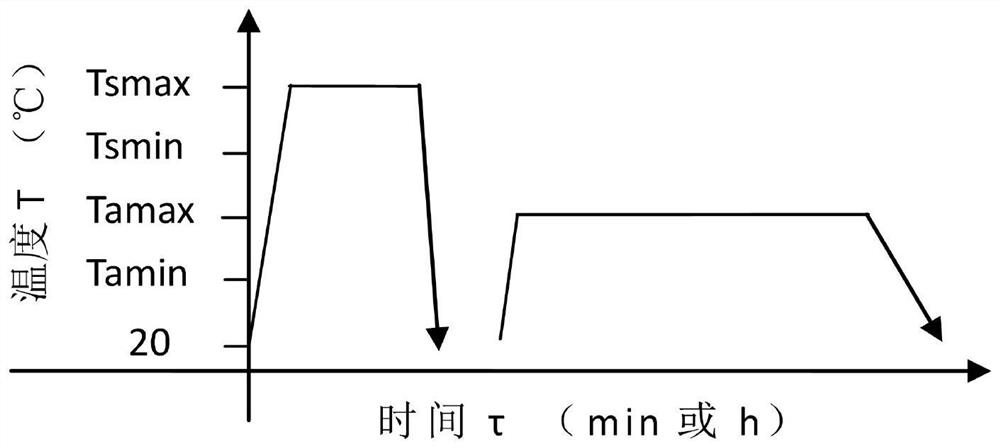

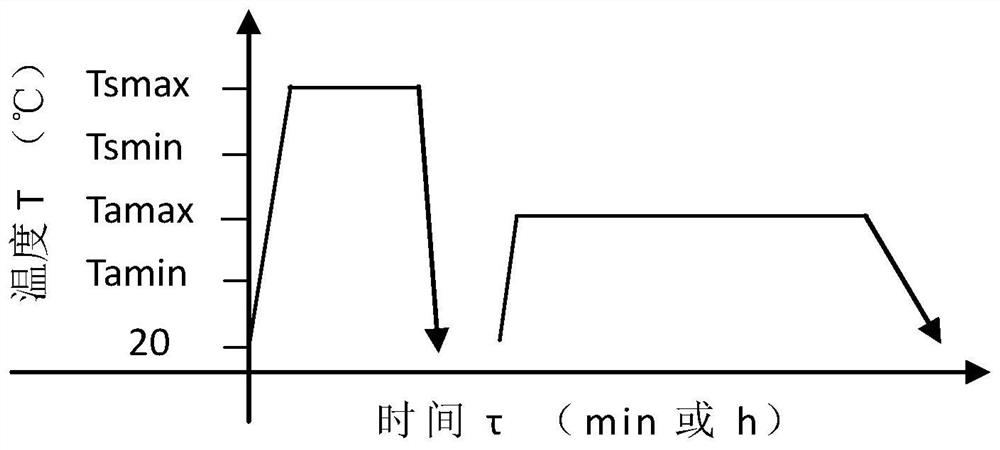

Rapid solid solution and rapid cooling and heating aging heat treatment method

The invention provides a rapid solid solution and rapid cooling and heating aging heat treatment method. The method comprises a rapid solid solution heat treatment process and a rapid cooling and heating aging heat treatment process. According to the scheme of the method, the specific heat treatment technical problems of poor quality stability, a low qualified rate, a low hardness, a low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, a short service life of high-temperature components, high cost and the like in heat treatment of austenitic stainless steel can be solved.

Owner:山西柴油机工业有限责任公司

Sufficient solid solution and sufficient heating aging composite heat treatment method

PendingCN114410931AQuality and reliabilityImprove quality stabilityHeat treatment process controlThermodynamicsHeating time

The invention provides a sufficient solid solution and sufficient heating aging composite heat treatment method. The method comprises a sufficient solid solution heat treatment process and a sufficient heating aging composite heat treatment process. According to the scheme, the specific heat treatment technical problems of'one-long-one-high three-difference five-low 'of existing austenitic stainless steel heat treatment, such as poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature components, high cost and the like, can be solved.

Owner:山西柴油机工业有限责任公司

Rapid solid solution and multi-time variable-temperature alternating aging composite heat treatment method starting from high temperature

PendingCN114395683AQuality and reliabilityTechnically feasibleHeat treatment process controlThermodynamicsHeating time

The invention provides a composite heat treatment method for rapid solid solution and multiple variable-temperature alternating aging starting from high temperature. The composite heat treatment method comprises a rapid solid solution heat treatment process and a composite heat treatment process for rapid high-temperature multiple variable-temperature alternating aging starting from high temperature. According to the scheme, the problems that mainstream austenitic stainless steel is poor in solid solution and aging heat treatment quality stability, low in qualified rate, relatively low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

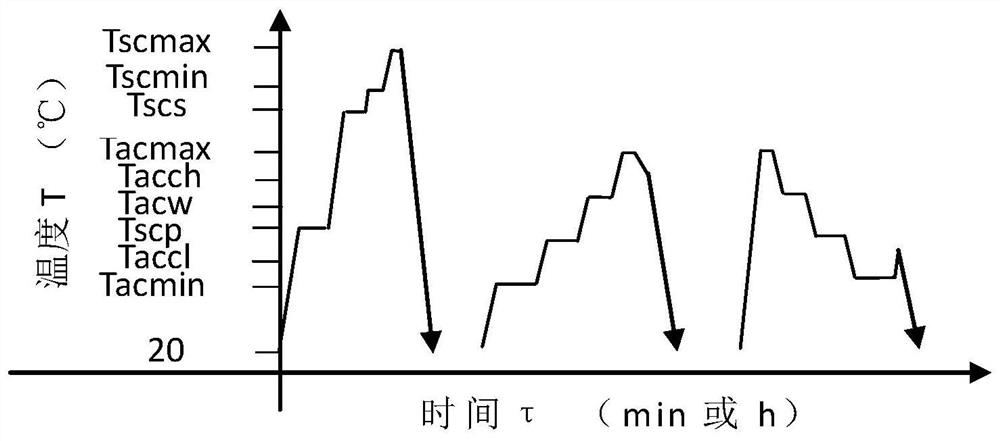

Critical solid solution and high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment method

The invention provides a critical solid solution and high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment method. The critical solid solution and high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment method comprises a critical solid solution heat treatment process and a critical high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment process. The scheme provided by the invention has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, can effectively develop the advantages and avoid the disadvantages of traditional major heat treatment methods of austenitic stainless steel, and special heattreatment technical the problems, namely being long in one aspect, high in one aspect, poor in four aspects and low in five aspects, that existing austenitic stainless steel heat treatment is poor inquality stability, low in the rate of qualified products, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time and low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components and parts are short in service life, and the cost is high, are fundamentally solved. The method isparticularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel involved in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

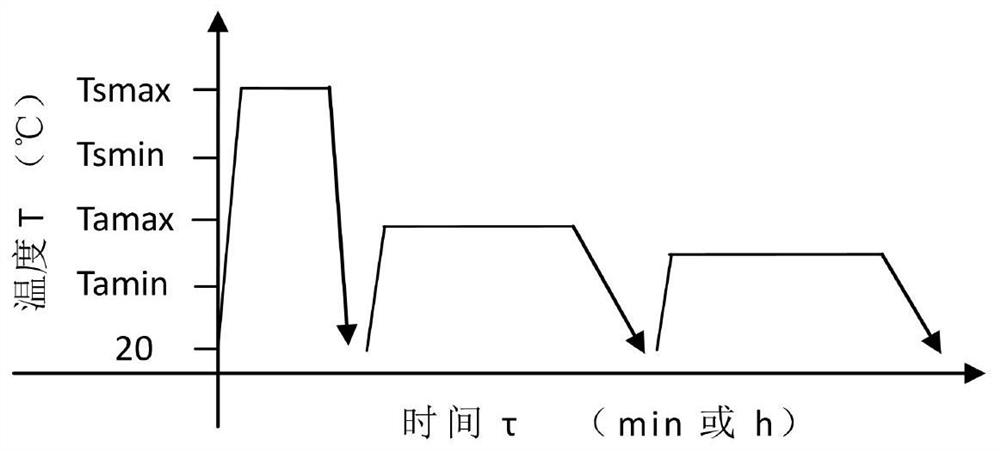

Critical solid solution and critical cooling and heating aging and annealing heat treatment method

The invention provides a critical solid solution and critical cooling and heating aging and annealing heat treatment method. The method comprises a critical solid solution heat treatment process and a critical cooling and heating aging and annealing heat treatment process. The scheme has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, and can effectively enhance the advantages and avoid the disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel; the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology problems are fundamentally solved. The method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

Critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method

The invention provides a critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method. The method comprises a critical solid solution heat treatment process and a critical multi-cooling variable-temperature aging and annealing heat treatment process. The scheme has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, and can effectively enhance the advantages and avoid the disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel, so that the problems that the existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like are fundamentally solved. The critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

Complex heat treatment method for sufficient solid solution and sufficient low-temperature-starting multiple alternating aging

PendingCN114395681AQuality and reliabilityTechnically feasibleHeat treatment process controlThermodynamicsHeating time

The invention provides a composite heat treatment method with sufficient solid solution and sufficient low-temperature multiple alternating aging. The method comprises a sufficient solid solution heat treatment process and a low-temperature multi-time alternating aging composite heat treatment process. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

Rapid solid solution and rapid starting low-temperature alternating aging composite heat treatment method

PendingCN114410910ATechnically feasibleProcess adaptabilityHeat treatment process controlHeating timeAustenite

The invention provides a composite heat treatment method for rapid solid solution and rapid starting from low-temperature alternating aging. The composite heat treatment method comprises a rapid solid solution heat treatment process and a composite heat treatment process for rapid starting from low-temperature alternating aging. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

Aging heat treatment method for critical solid solution as well as critical temperature rise, temperature fall and temperature variation

The invention provides an aging heat treatment method for critical solid solution as well as critical temperature rise, temperature fall and temperature variation. The aging heat treatment method comprises a critical solid solution heat treatment process as well as a critical temperature rise, temperature fall and temperature variation aging heat treatment process. The aging heat treatment method provided by the invention has technical feasibility, process adaptability, quality reliability, economic rationality and use safety; the advantages and disadvantages of a traditional mainstream heat treatment method for austenitic stainless steel can be effectively enhanced and avoided; the specific heat treatment technology problems that in the existing austenitic stainless steel heat treatment process, the quality stability is low, the rate of qualified products is low, the hardness is relatively low, the mechanical performance is low, the consistency is poor, the discoloration and corrosion resisting capacity is poor, the heating time is long, the efficiency is low, the heating reliability of heat treatment equipment is poor, the service life of high-temperature components is short, and the cost is high can be fundamentally solved; and the aging heat treatment method is particularly applicable to the technical fields of hot-working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel in steel mills and manufacturing plants.

Owner:山西柴油机工业有限责任公司

Complex heat treatment method for sufficient solid solution and multiple variable-temperature alternating aging starting from low temperature

PendingCN114410923AReduce total solution and aging holding timeTechnically feasibleHeat treatment process controlAustenitic stainless steelProcess engineering

The invention provides a composite heat treatment method for sufficient solid solution and multiple variable-temperature alternating aging starting from low temperature. The method comprises a sufficient solid solution heat treatment process and a low-temperature multi-time variable-temperature alternating aging composite heat treatment process which is sufficiently started from the low-temperature multi-time variable-temperature alternating aging composite heat treatment process. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

Critical solid solution and multi-time variable-temperature alternating aging composite heat treatment method starting from low temperature

PendingCN114410925ATechnically feasibleProcess adaptabilityHeat treatment process controlHeating timeAustenite

The invention provides a critical solid solution and multi-time variable-temperature alternating aging composite heat treatment method starting from low temperature. The method comprises a critical solid solution heat treatment process and a critical-starting low-temperature multi-time variable-temperature alternating aging composite heat treatment process. According to the scheme, the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like can be solved. The heating reliability of heat treatment equipment is poor; the service life of a high-temperature component is short; the cost is high; and the like.

Owner:山西柴油机工业有限责任公司

Rapid solid solution and rapid heating aging heat treatment method

The invention provides a rapid solid solution and rapid heating aging heat treatment method. The rapid solid solution and rapid heating aging heat treatment method comprises the steps of a rapid solid solution heat treatment process and a rapid heating aging heat treatment process. According to the scheme, the specific heat treatment technology theory and practice problems of poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heating equipment, short service life of high-temperature components and high cost and the like of austenitic stainless steel heat treatment are solved.

Owner:山西柴油机工业有限责任公司

Sufficient solid solution and sufficient heating and cooling variable-temperature aging heat treatment method

The invention provides a sufficient solid solution and sufficient heating and cooling variable-temperature aging heat treatment method. The method comprises a sufficient solid solution heat treatment process, a sufficient heating aging heat treatment process and a sufficient cooling variable-temperature aging heat treatment process. According to the scheme, the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology problems can be solved.

Owner:山西柴油机工业有限责任公司

Rapid solid solution and rapid cooling, heating and variable-temperature aging heat treatment method

The invention provides a rapid solid solution and rapid cooling, heating and variable-temperature aging heat treatment method. The heat treatment method comprises a rapid solid solution heat treatment process and a rapid cooling, heating and variable-temperature aging heat treatment process. According to the scheme, the specific heat treatment technical problems of low quality stability, qualified rate, hardness, mechanical property and consistency, long heating time, low efficiency, low heating reliability of heat treatment equipment, short service life and high cost of high-temperature components and the like during austenitic stainless steel heat treatment can be solved.

Owner:山西柴油机工业有限责任公司

Sufficient solid solution and sufficient multi-cooling variable-temperature aging heat treatment method

PendingCN114395685ATechnically feasibleProcess adaptabilityHeat treatment process controlThermodynamicsHeating time

The invention provides a sufficient solid solution and sufficient multiple cooling variable-temperature aging heat treatment method. The method comprises a sufficient solid solution heat treatment process and a sufficient multiple-cooling variable-temperature aging heat treatment process. According to the scheme, the specific heat treatment technical problems of'one-long-one-high three-difference five-low 'of existing austenitic stainless steel heat treatment, such as poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature components, high cost and the like, can be solved.

Owner:山西柴油机工业有限责任公司

Aging heat treatment method for critical solid solution as well as critical temperature rise and temperature fall

The invention provides an aging heat treatment method for critical solid solution as well as critical temperature rise and temperature fall. The aging heat treatment method comprises a critical solid solution heat treatment process, a critical temperature rise aging heat treatment process and a critical temperature fall aging heat treatment process. The aging heat treatment method provided by the invention has technical feasibility, process adaptability, quality reliability, economic rationality and use safety; the advantages and disadvantages of a traditional mainstream heat treatment method for austenitic stainless steel can be effectively enhanced and avoided; the specific heat treatment technology problems that in the existing austenitic stainless steel heat treatment process, the quality stability is low, the rate of qualified products is low, the hardness is relatively low, the mechanical performance is low, the consistency is poor, the discoloration and corrosion resisting capacity is poor, the heating time is long, the efficiency is low, the heating reliability of heat treatment equipment is poor, the service life of high-temperature components is short, and the cost is high can be fundamentally solved; and the aging heat treatment method is particularly applicable to the technical fields of hot-working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel in steel mills and manufacturing plants.

Owner:山西柴油机工业有限责任公司

Critical solid solution and critical starting low-temperature alternating aging composite heat treatment method

PendingCN114410915AGood workmanshipIncrease solid solution and aging strengthening phaseHeat treatment process controlAustenitic stainless steelHeating time

The invention provides a critical solid solution and critical-beginning low-temperature alternating aging composite heat treatment method. The method comprises a critical solid solution heat treatment process and a critical low-temperature alternating aging composite heat treatment process. According to the scheme, the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like can be solved. The heating reliability of heat treatment equipment is poor; the service life of a high-temperature component is short; the cost is high; and the like.

Owner:山西柴油机工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com