A forging die formed by combined die forging

A forging die and die forging technology, applied in the field of forging dies formed by combined die forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, content and advantages of the present invention clearer, the specific implementations of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

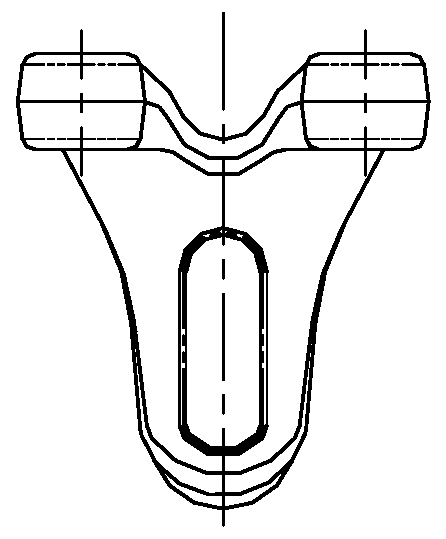

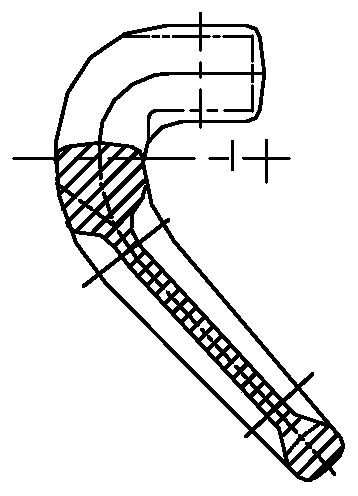

[0041] The forging die for combined die forging of the present invention includes a hot flat forging die and a hot bending forging die, which are respectively aimed at the first hot flat die forging and the second hot bending of the hook combined precision die forging process. Designed for die forging.

[0042] (1) The first hot flat forging forming: need to rely on a set of hot flat forging die to achieve, that is, heating the round steel billet to the initial forging temperature specified by the process, drawing and flattening in the hot flat forging die The billet is formed on the blank die cavity, the pre-forging forming in the pre-forging die cavity of the hot flat forging die, the final forging forming in the final forging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com