Collapsible control lever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

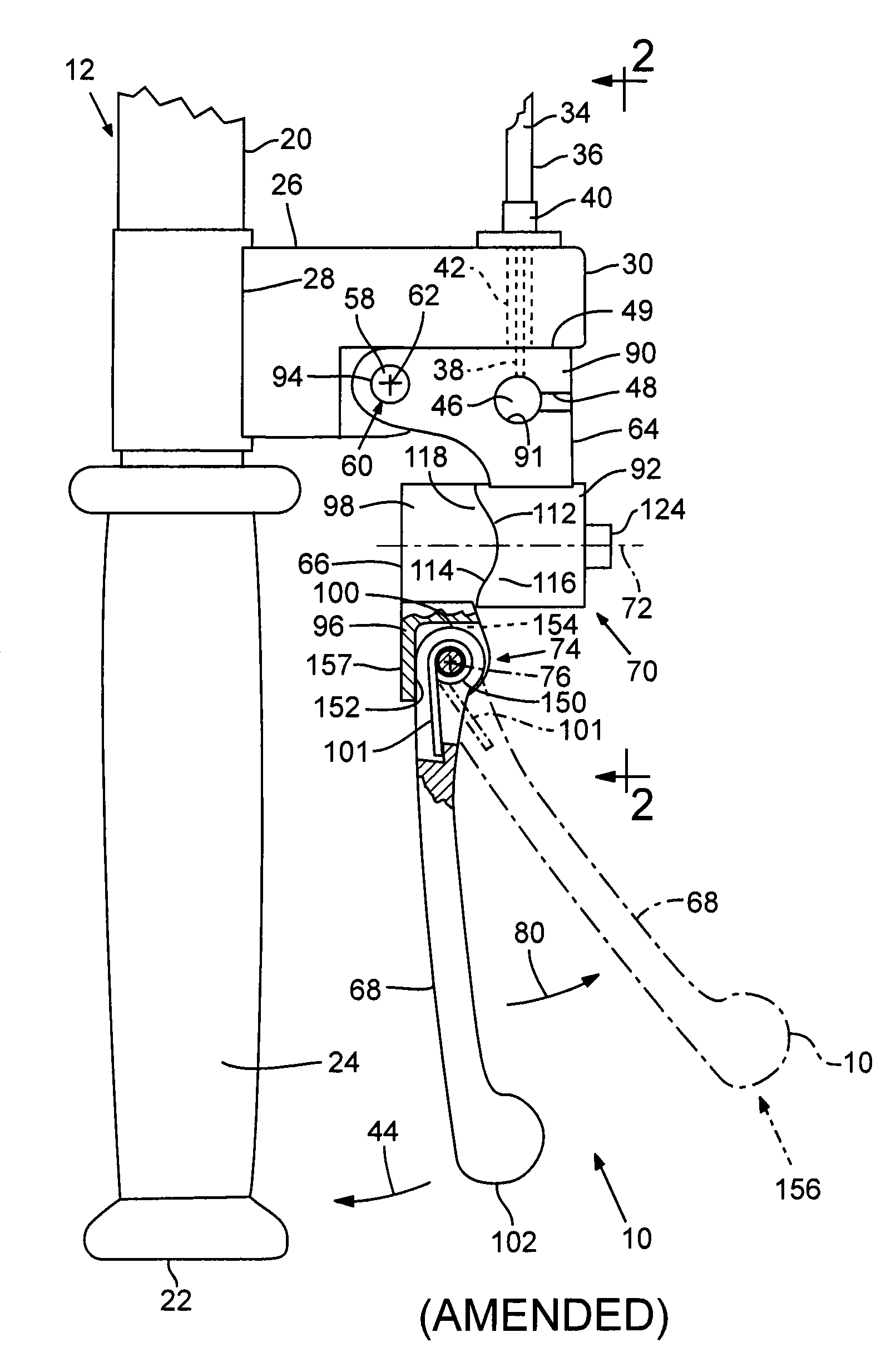

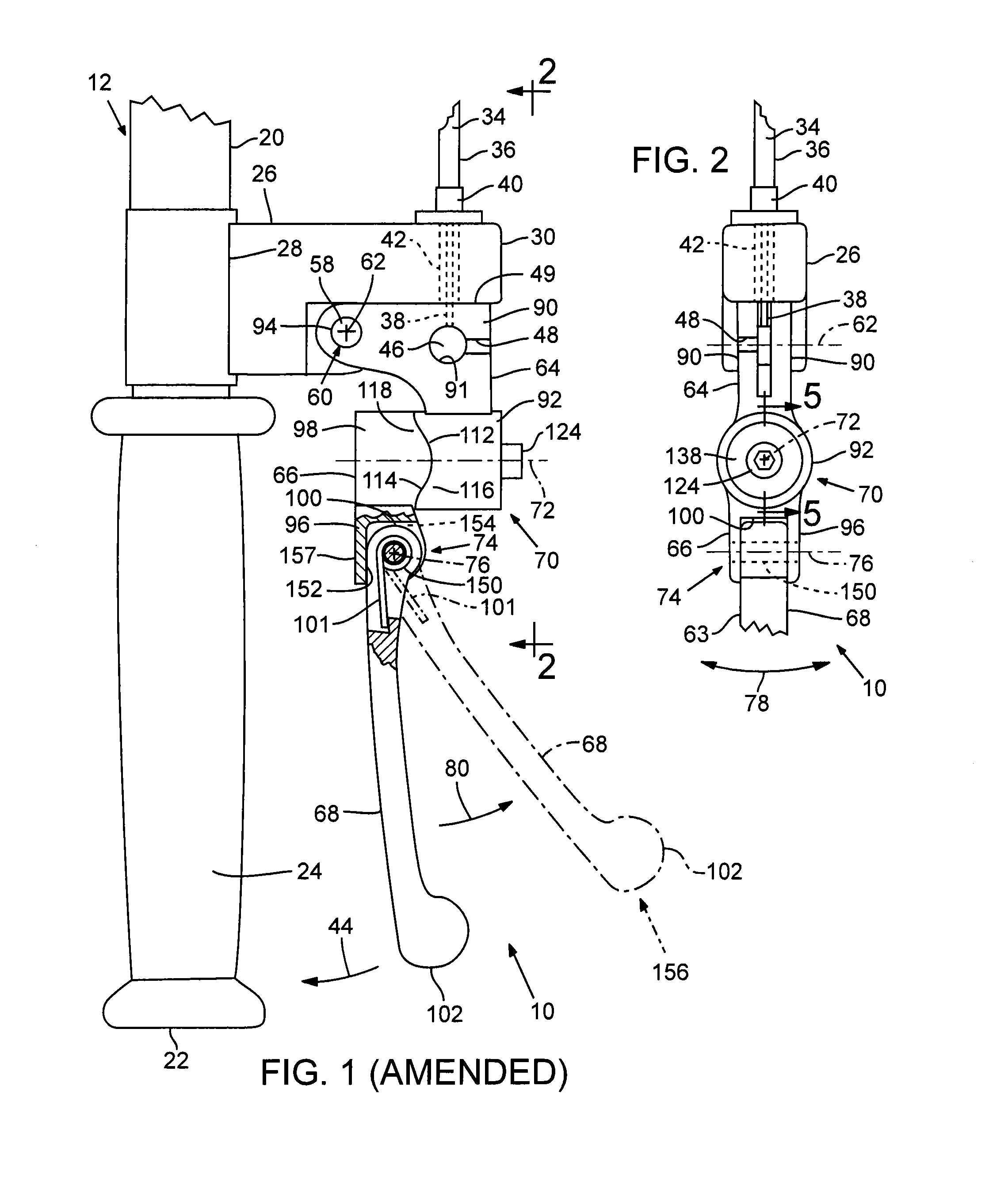

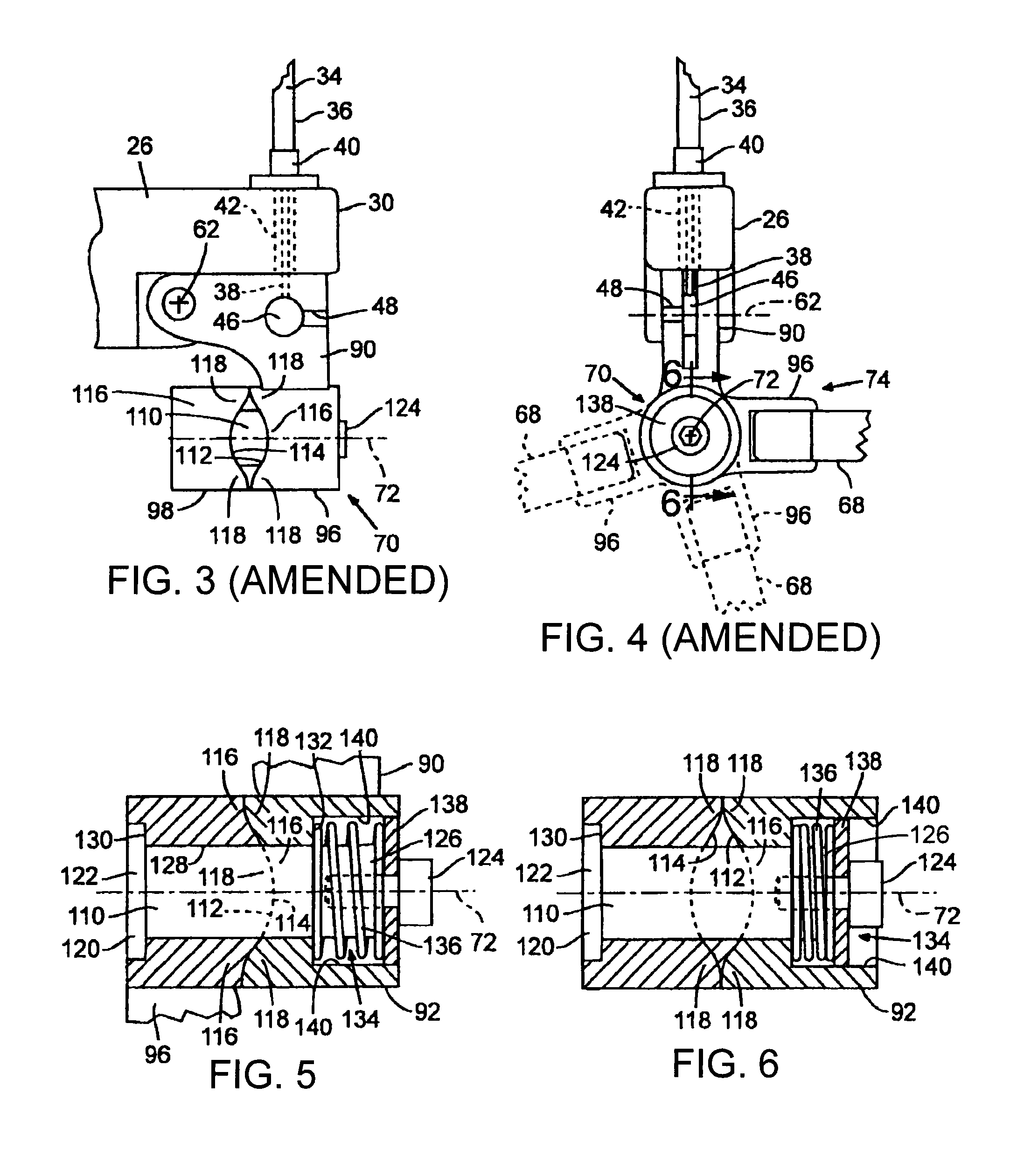

[0032]A collapsible lever 10 constructed accordingly to an embodiment of the invention for use, in the present case, with a cable lever control system 12 is shown in FIGS. 1-6.

[0033]The construction and use of such a cable lever control system 12 is known. Accordingly, to provide a comprehensive disclosure without unduly lengthening the specification, this specification incorporates by reference the disclosures of U.S. Pat. Nos. 4,088,040 to Ross-Myring, 4,726,252 to Dawson, and 4,730,509 to Homady. These references provide greater detail regarding the general construction and use of cable lever control systems.

[0034]In general, as shown in FIG. 1, the cable lever control system 12 includes a handlebar 20 having an end 22 with the cable control system 12 secured near said end. A handle grip 24, usually constructed of a resilient material, is secured to the end portion of the handlebar 20. A pivot mount 26 extends from the handlebar 20 generally perpendicular to and near the handle g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com