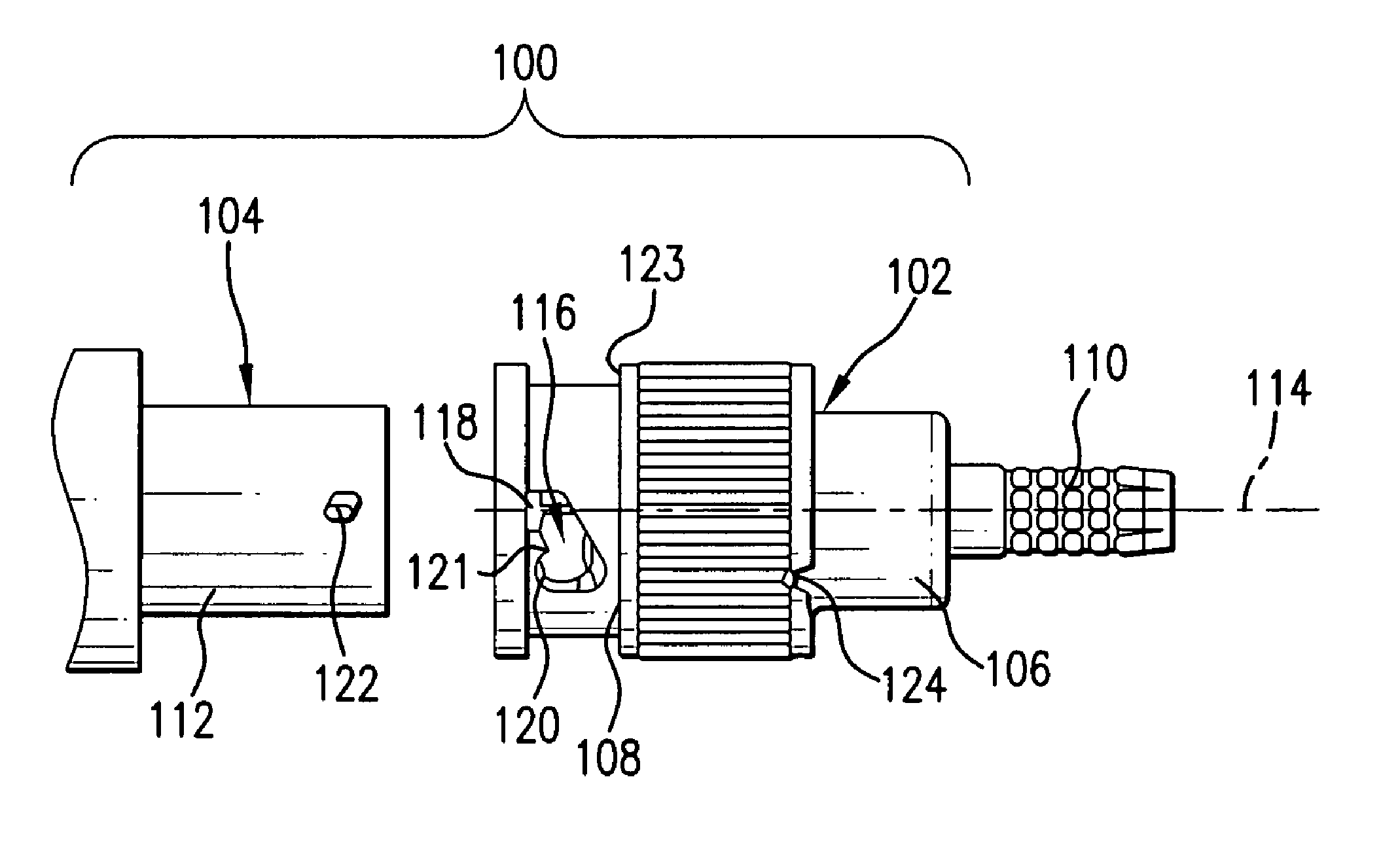

Miniature BNC connector

a technology of bnc connector and bnc connector, which is applied in the direction of coupling device connection, coupling device details, coupling/disassembly parts, etc., can solve the problems of impeded further increase in connection densities, mechanical footprint of standard bnc connector, and lack of certain advantages, so as to achieve small and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Overview

[0030]While specific configurations and arrangements are discussed, it should be understood that this is done for illustrative purposes only. A person skilled in the relevant art will recognize that other configurations and arrangements can be used without departing from the spirit and scope of the invention. It will be apparent to a person skilled in the relevant art that this invention can also be employed in a variety of other devices and applications.

[0031]When working in tight areas, it is sometimes hard to determine if a plug and jack-side of a connector are fully mated or engaged. Embodiments of the present invention provide a jack-side connector having a first securing device and a plug-side connector having a sleeve rotatably coupled thereto. The sleeve has a second securing device that is complementary to the first securing device and an indicator located on an edge of the sleeve. The indicator is contrasted against a characteristic (e.g., color, material, etc.) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com