Downhole adjustable bent housing for directional drilling

a directional drilling and adjustable technology, applied in directional drilling, drilling machines and methods, borehole/well accessories, etc., can solve the problem of complex control schemes of the rotational position of each housing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

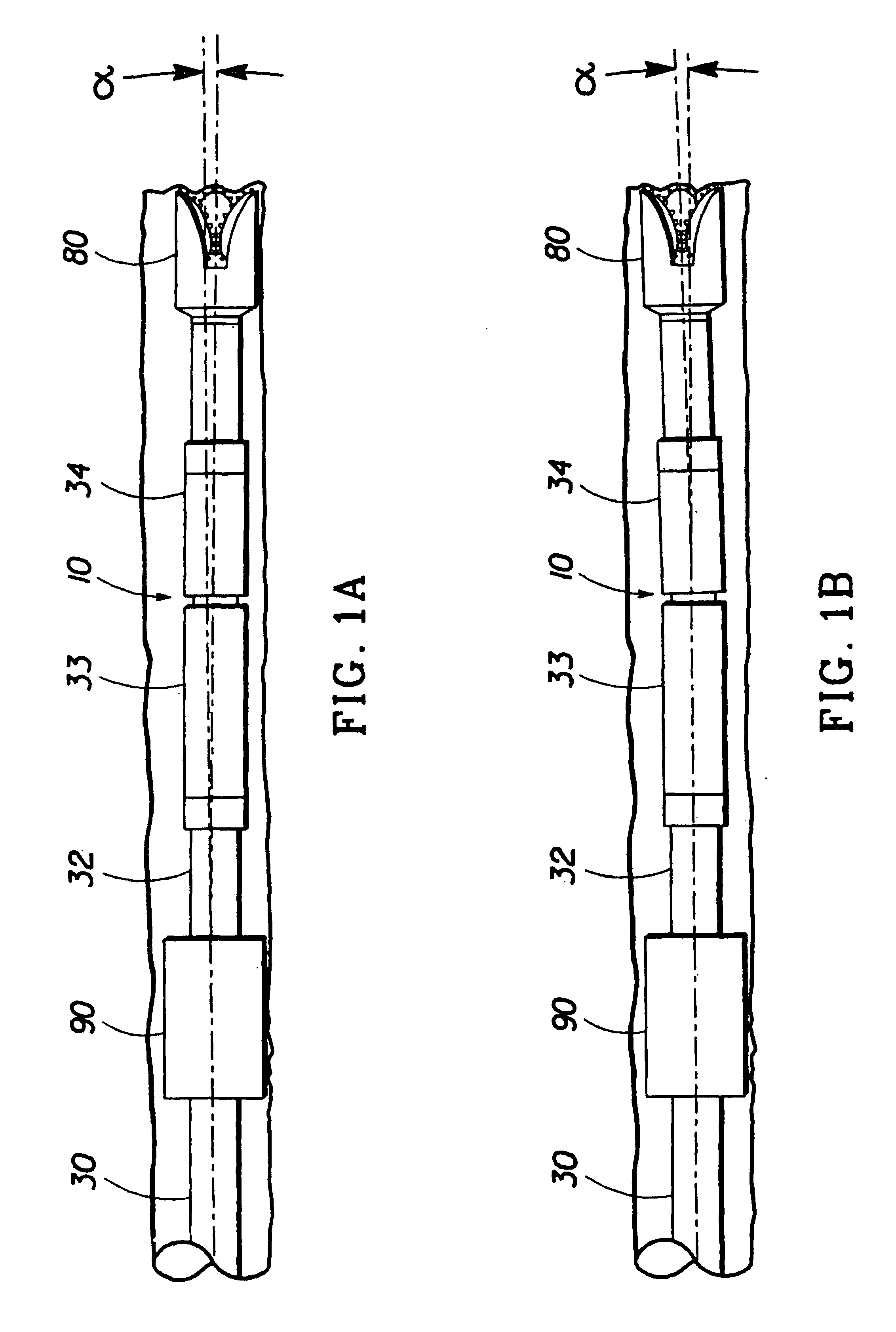

[0032]FIG. 1A shows a downhole adjustable bent housing 10 connected between a mud motor and a drill bit in accordance with the present invention. The downhole adjustable bent housing 10 in this configuration is set to have a slight downward angular deviation, thereby influencing the drill bit to drop angle, or turn downwardly, from its existing path. FIG. 1B shows how the downhole adjustable bent housing 10 may impart an upward angular deviation to the BHA that affects the angle of attack of the bit against the bore wall. The angular deviation imparted by the downhole adjustable bent housing 10 is a slight upward angular deviation thereby influencing the drill bit to build angle, or turn upwardly, from its existing path.

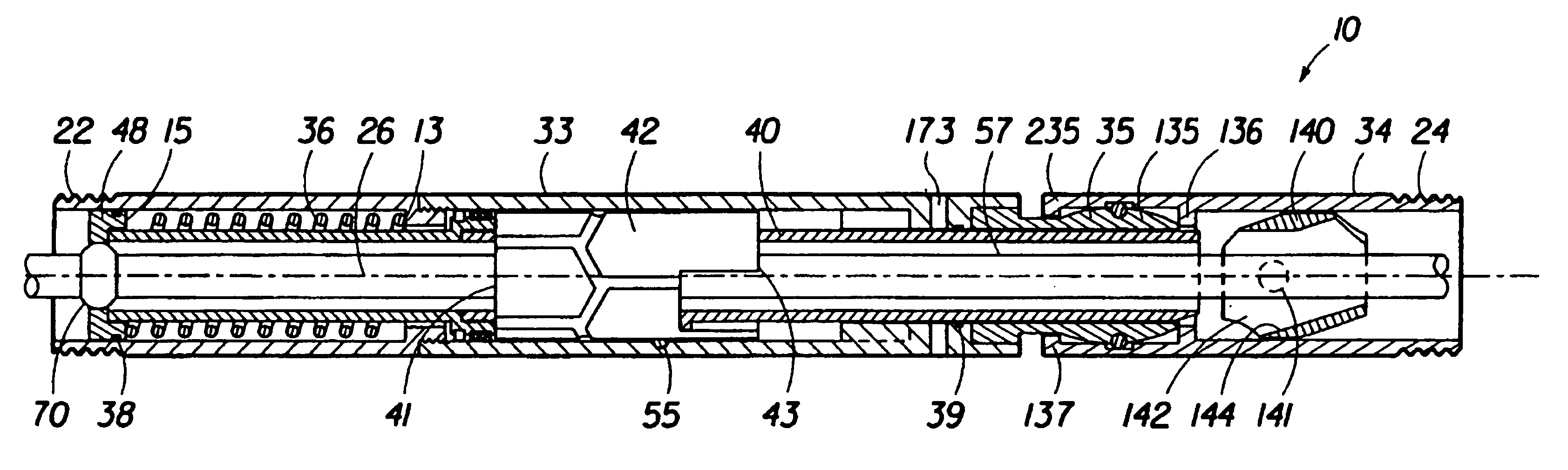

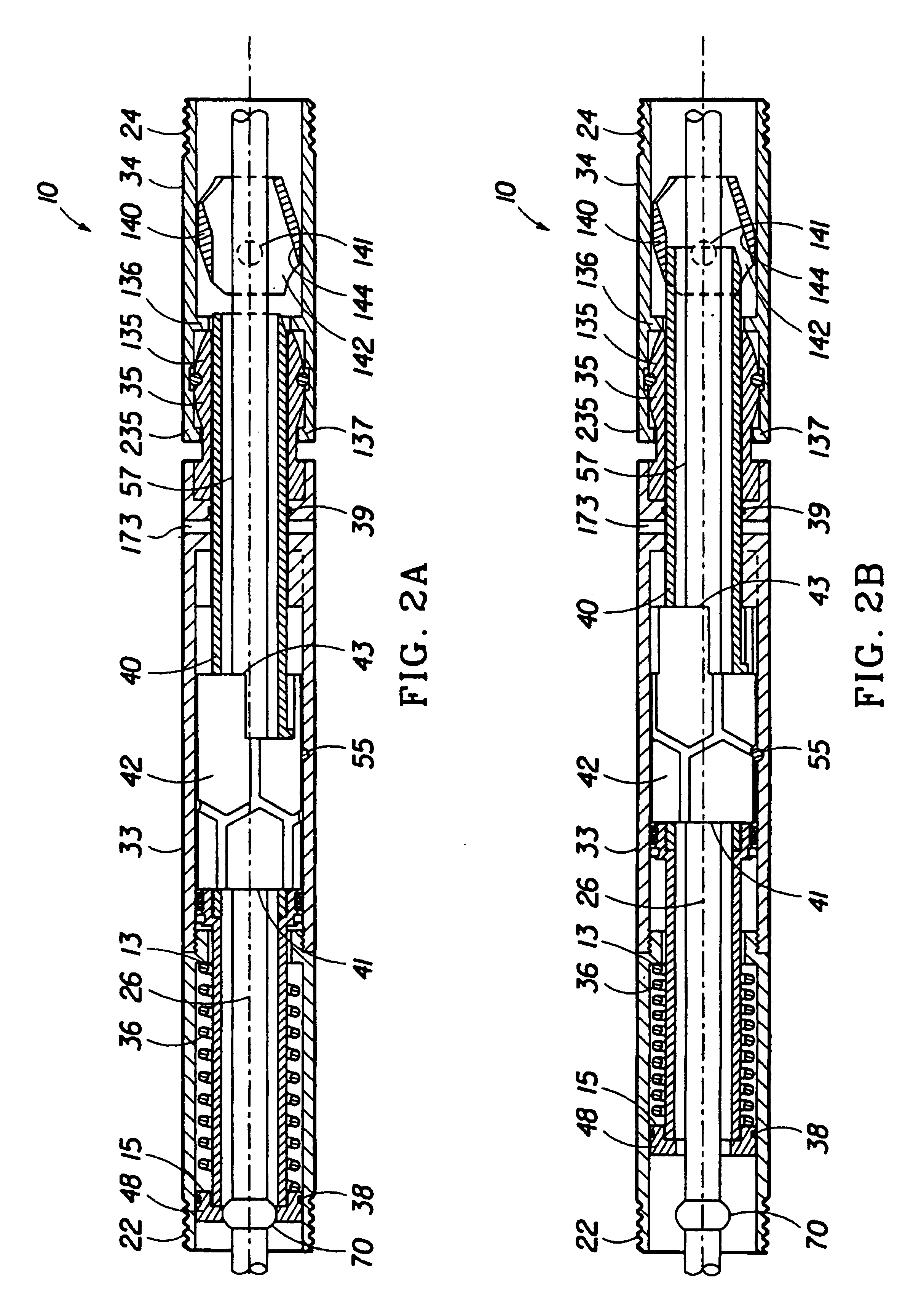

[0033]FIG. 2A shows the general configuration of a preferred embodiment of the downhole adjustable bent housing 10, in its inactive position. The downhole adjustable bent housing 10 has a mandrel housing 33 and a member housing 34 pivotally joined at a knuckle 35. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com