Integrated disposable ear piercing earring and clutch cartridge and ear piercing instrument for use therewith

a technology for ear piercing instruments and cartridges, which is applied in the field of disposable ear piercing earring and clutch cartridges and instruments for use there, can solve the problems of increasing the chance of cross contamination between successive ear piercing patients and the ear piercing instrument operator, affecting the accuracy of ear piercing, and reducing the amount of handling of ear piercing earring and clutch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

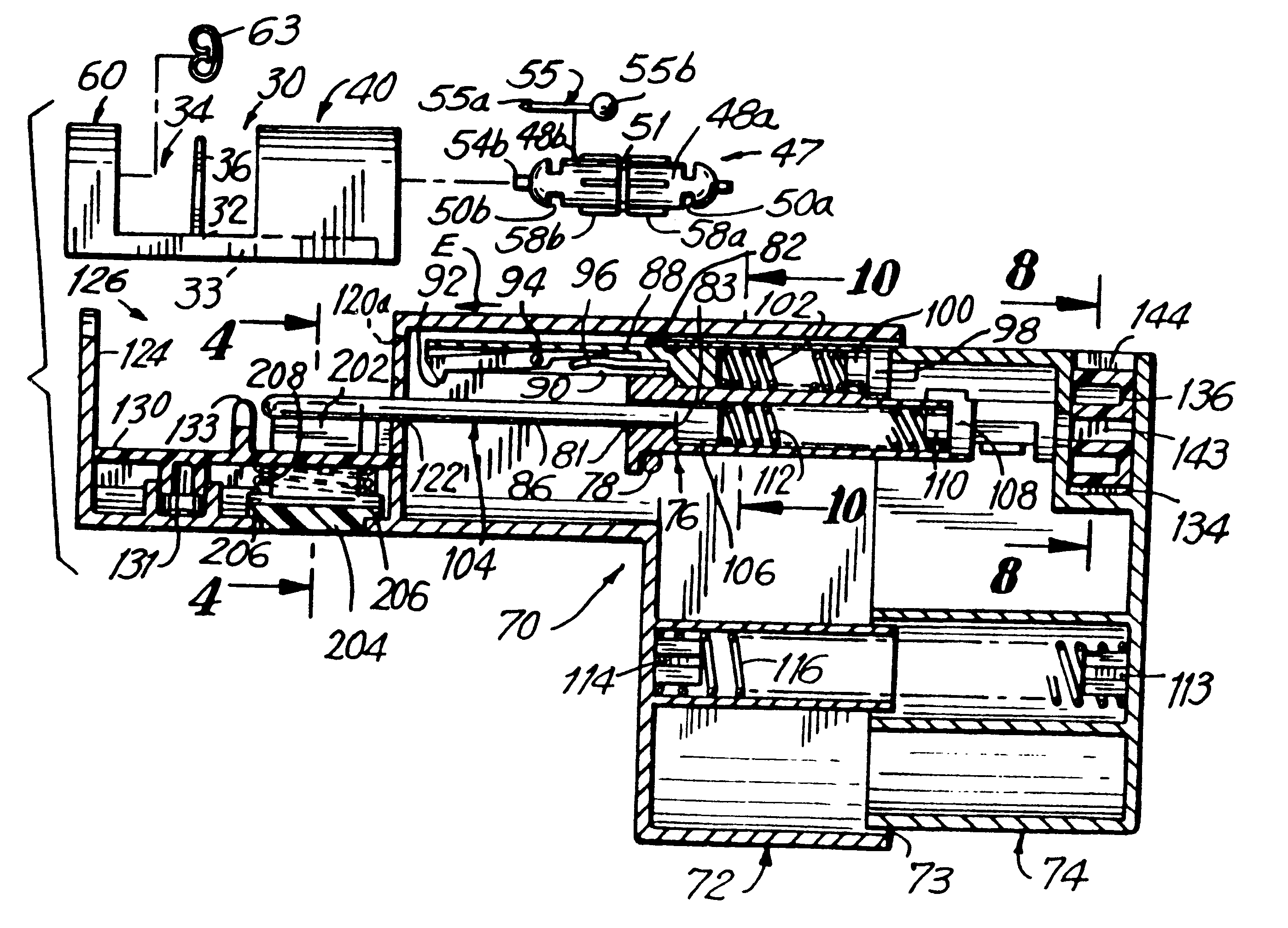

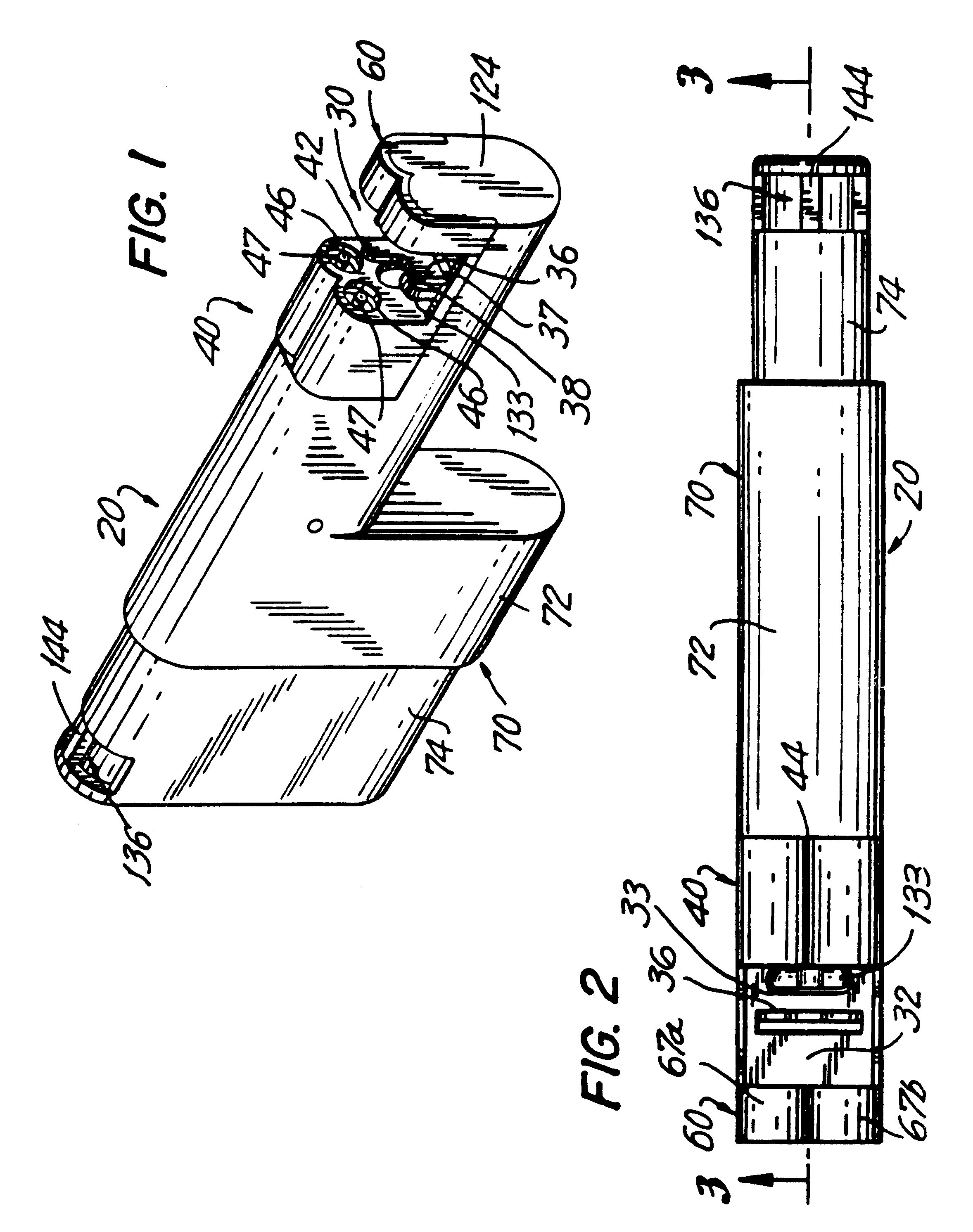

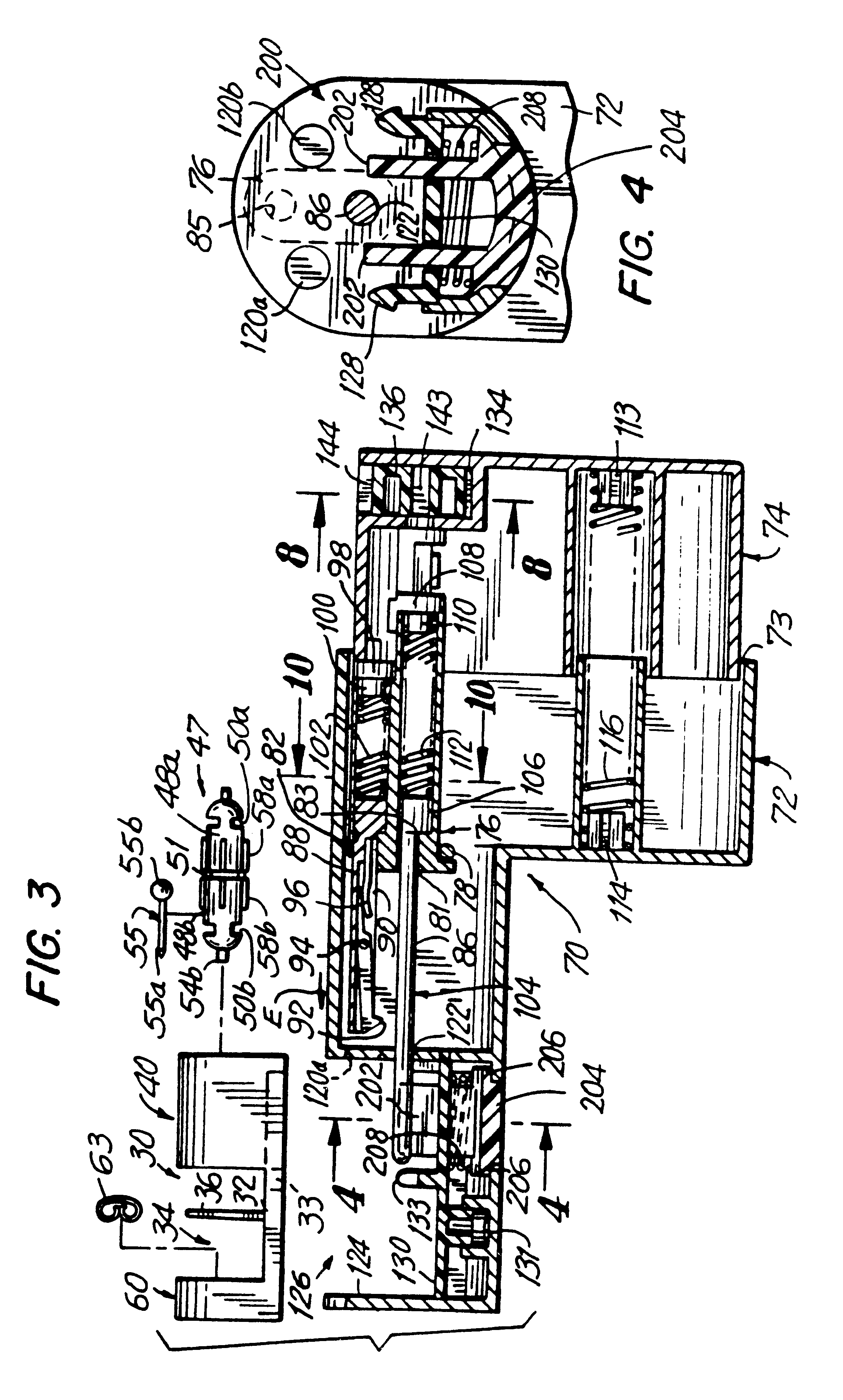

Reference is now had to FIGS. 1-6 wherein an ear piercing assembly, constructed in accordance with a preferred embodiment of the instant invention, and generally indicated as 20, is depicted. Ear piercing assembly 20 includes a unitary ear piercing earring ("earring") and clutch cartridge assembly ("cartridge assembly") 30 and an ear piercing instrument generally indicated as 70. Cartridge assembly 30 includes an ear piercing earring retaining sub-assembly 40 and a clutch retaining sub-assembly, generally indicated as 60.

Cartridge assembly 30 is formed as an integral molded piece. Earring retaining sub-assembly 40 is separated from clutch retaining sub-assembly 60 by a floor 32 forming a saddle region 34 therebetween. A pivotable clamp 36 is affixed to floor 32 within saddle region 34. A hinge 37 is formed between the clamp 36 and floor 32 allowing movement of clamp 36 towards clutch retaining sub-assembly 60. Floor 32 is formed with a slot 33 therein.

Earring retaining sub-assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com