Packaging arrangement for contact lenses

a technology for packaging arrangements and contact lenses, applied in the field of packaging arrangements, can solve the problems of grasping and removing, and the implementation of an extremely complicated procedur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

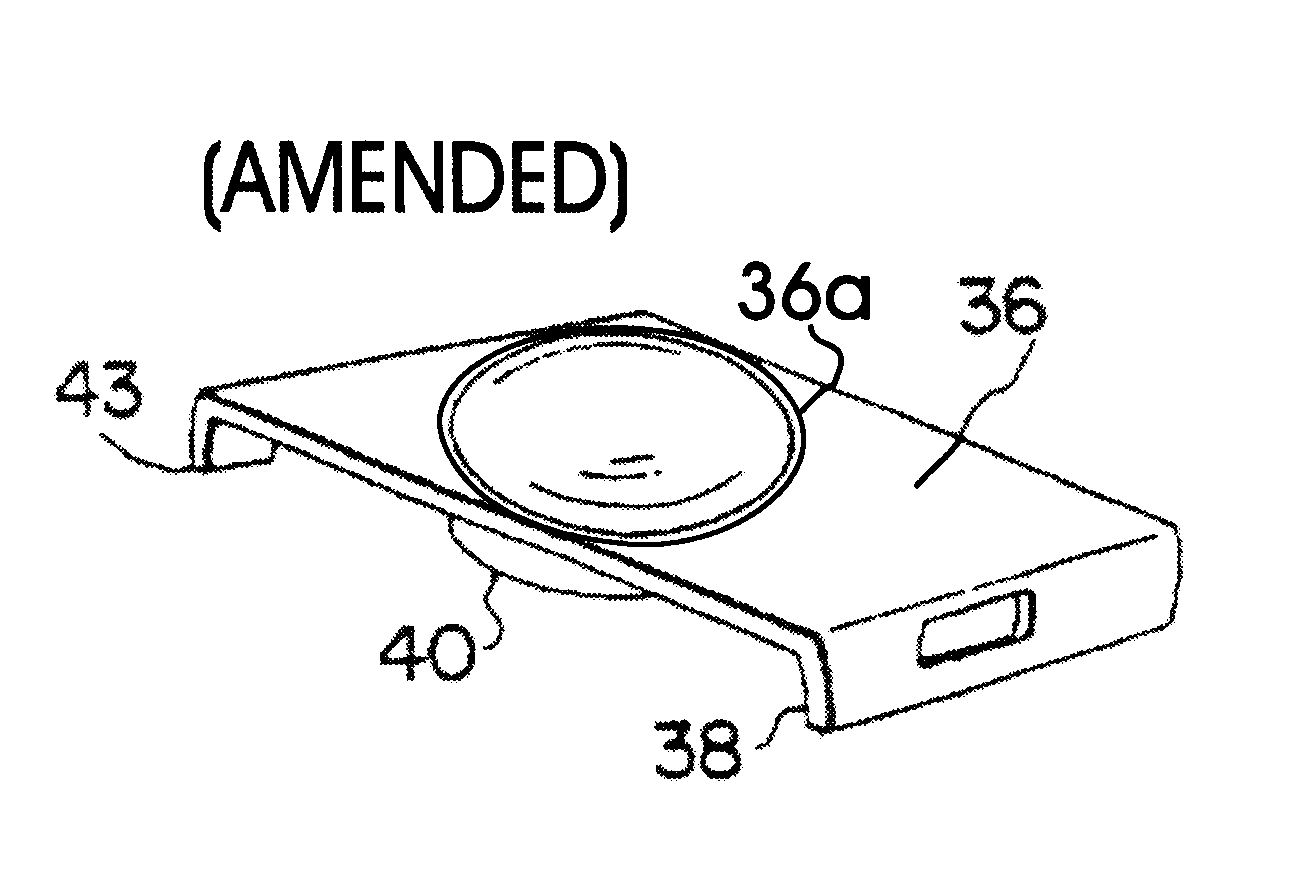

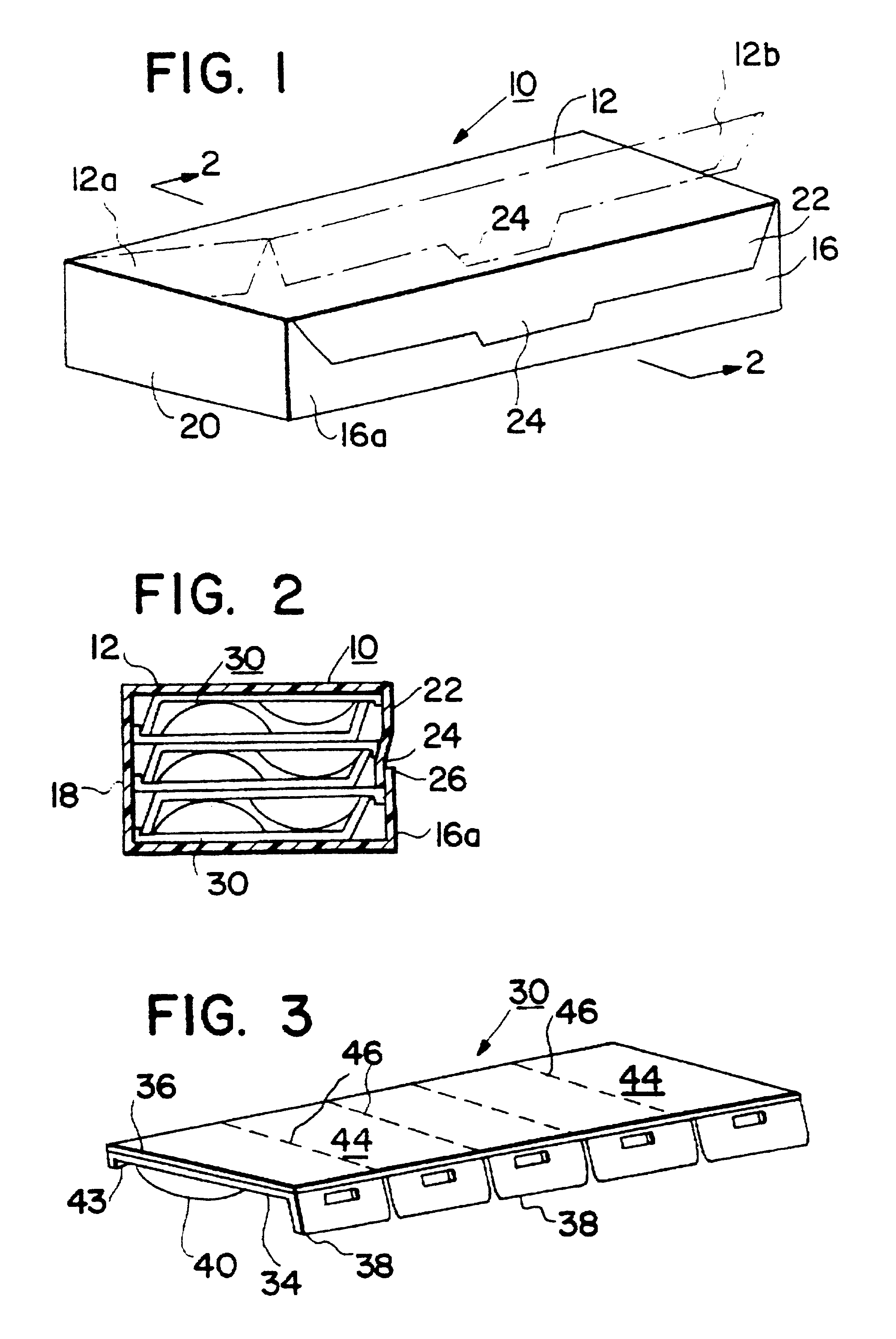

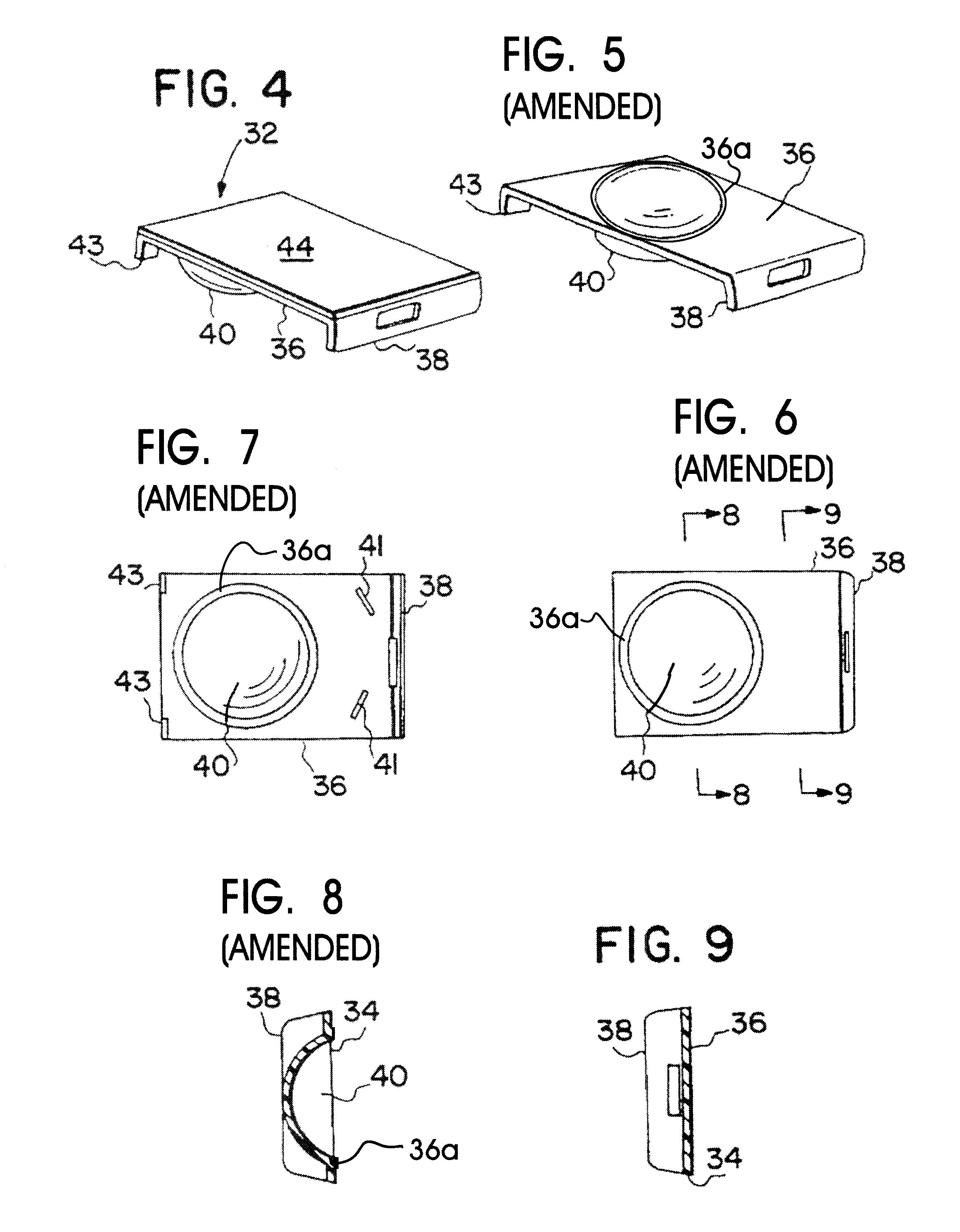

Referring now in more specific detail to the drawings, and in particular to FIGS. 1 and 2, there is illustrated a generally rectangular carton 10 which is adapted to receive a plurality of planar arrays of packaging arrangements for the sealed containment of contact lenses, especially disposable hydrophilic contact lenses, as described in more specific detail hereinbelow.

The rectangular carton 10, which is preferably constituted of paperboard, includes flat top and bottom wall panels 12 and 14, and front and rear walls or panels 16 and, respectively, 18 which are adapted to be closed by being folded from a carton blank along suitable fold lines, and opposite ends 20; (only one shown) through an adhesive or glued construction as is known in the carton forming technology. The top wall panel 12 is adapted to be swung upwardly about a rear hinge line, as shown by the phantom illustration, to open the carton 10, and includes side flaps 12a, 12b which may be tucked within the confines of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com