Mixed metallocene catalyst composition and method for preparing polyolefin using the same

a metallocene catalyst and polyolefin technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of significantly lowering the producibility of some products, difficult to obtain desired physical properties, and inability to achieve desired physical properties, etc., to achieve superior mechanical properties and processability, and wide molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples [UNK]

Examples 1˜10

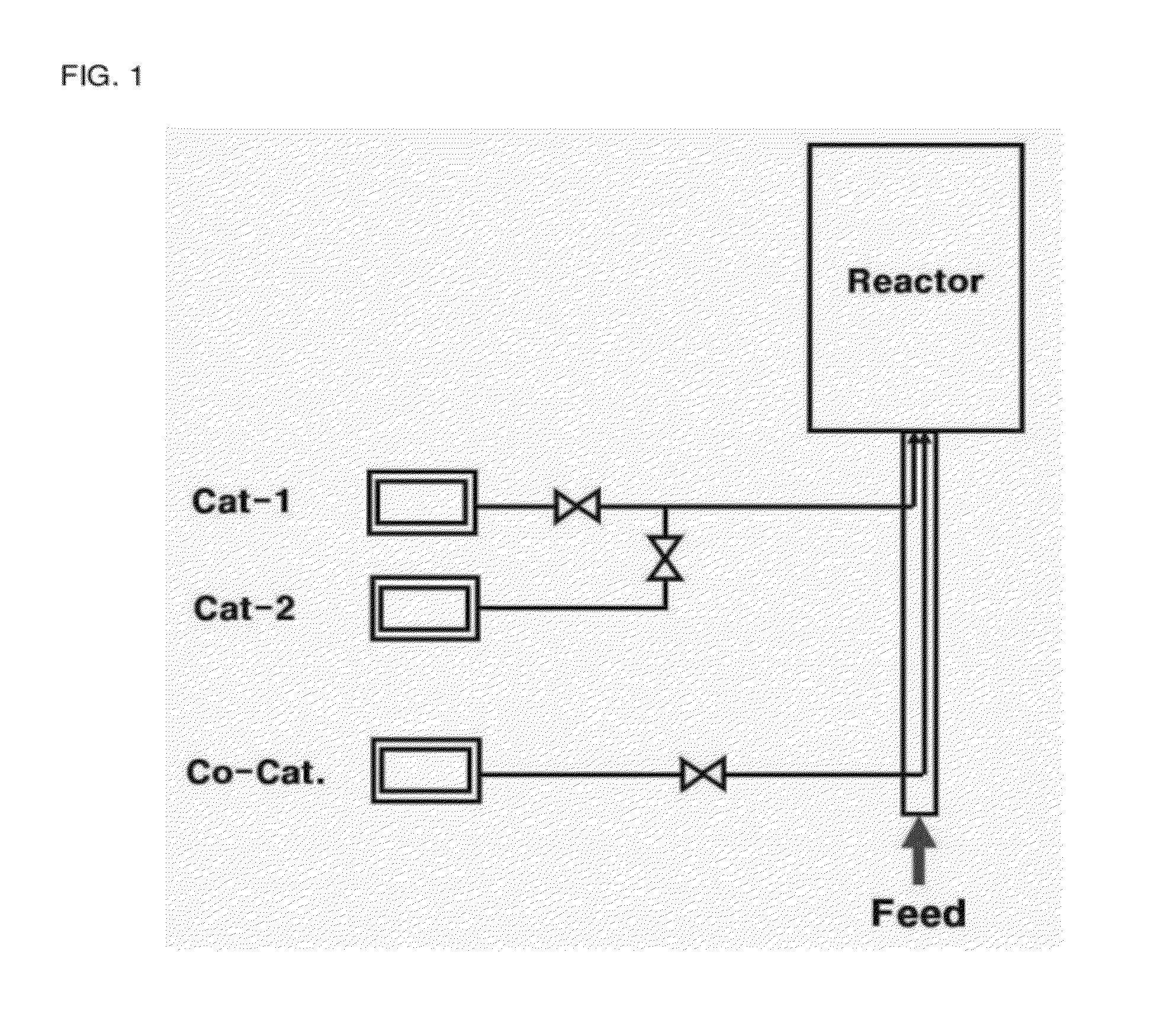

[0082]A hexane solvent and 1-octene and ethylene monomers were supplied into a 1.5 L continuous stirred reactor preheated to 100˜150° C. at a pressure of 89 bar. A first metallocene catalyst (LGC-001, LG Chemical), a second metallocene catalyst (K, LG Chemical), a first cocatalyst of dimethylanilinium tetrakis(pentafluorophenyl)borate, and a second cocatalyst of triisobutylaluminum were supplied from a catalyst storage tank to the reactor to perform a copolymerization reaction. The polymerization was performed at a relatively high temperature of 140˜180° C., and the polymer solution formed by the copolymerization reaction was supplied into a solvent separator to mostly remove the solvent. The resultant was passed through cooling water and a cutter to give particulate polymers.

experimental examples

Experimental Example 1

Measurement of Reaction Yield and Density of Polyolefin

[0087](1) Yield of the polyolefin prepared in the examples and comparative examples was determined by the weight of particles obtained for 10 minutes.

[0088](2) Density of the polyolefin prepared in the examples and comparative examples was determined using a Mettler scale after preparing a sheet having a thickness of 3 mm and a diameter of 2 cm using a press mold at 180° C. and cooling it at 10° C. / min.

[0089]Reaction yield and density of the polyolefin in the examples and comparative examples are shown in the following Table 2.

[0090]

TABLE 2Reaction Yield and Density of Polyolefin in Examples andComparative ExamplesYield (g / 10 min)Density (g / cc)Example 1110.40.906Example 2119.70.910Example 3153.20.883Example 4145.00.878Example 5118.20.906Example 6152.00.883Example 7106.20.886Example 8101.60.887Example 998.10.890Example 10105.60.892Comparative104.50.912Example 1Comparative133.70.880Example 2Comparative100.30....

experimental example 2

Measurement of Molecular Weight and Molecular Weight Distribution

[0092]A number-average molecular weight (Mn) and a weight-average molecular weight (Mw) of the polyolefins prepared in Examples 5 to 10 and Comparative Examples 2 and 3 were measured using a high-temperature GPC (PL-GPC220) instrument, and a molecular weight distribution (MWD, Mw / Mn) was determined therefrom.

[0093]The molecular weight and molecular weight distribution of the polyolefins of Examples 5 to 10 and Comparative Examples 2 and 3 are shown in the following Table 3.

[0094]

TABLE 3Molecular Weight and Molecular Weight Distribution of Polyolefins ofExamples 5 to 10 and Comparative Examples 2 and 3MWDMnMw(Mw / Mn)Example 511,95263,0005.2712Example 613,71654,0004.456Example 720,10087,2004.34Example 818,90086,3004.57Example 916,10077,5004.81Example 1015,40079,6005.17Comparative27,79463,5502.2865Example 2Comparative41,000105,40002.57Example 3

[0095]As shown in Table 3, polyolefins prepared in the examples were found to ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com