Composite lift gate deformable section

a technology of lift gate and deformation section, which is applied in the direction of monocoque construction, domestic objects, vehicle bodies, etc., can solve the problems of excessive cost of repairing dents and mechanisms in lift gate collisions, large damage caused in the impact zone, etc., and achieve the effect of more rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

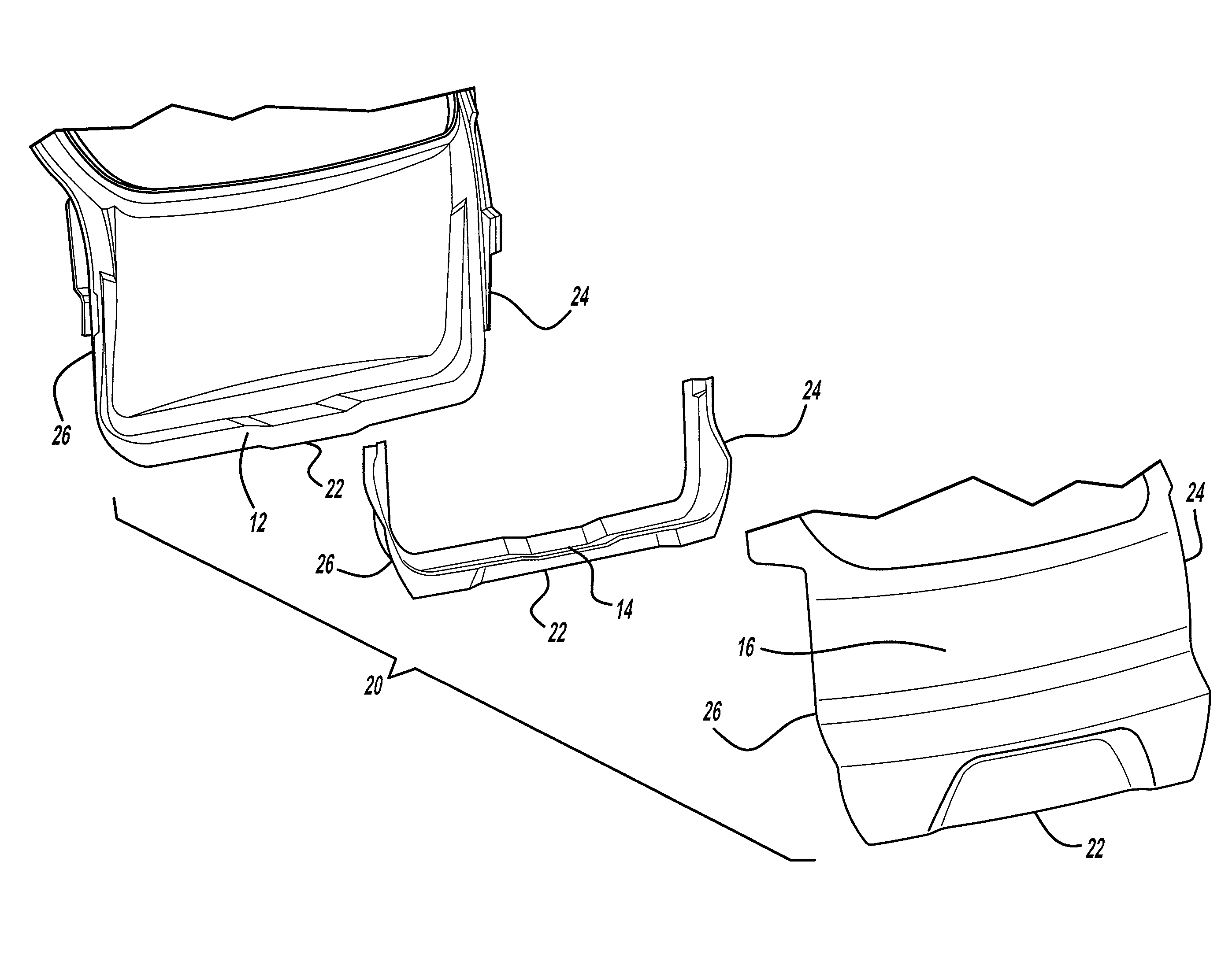

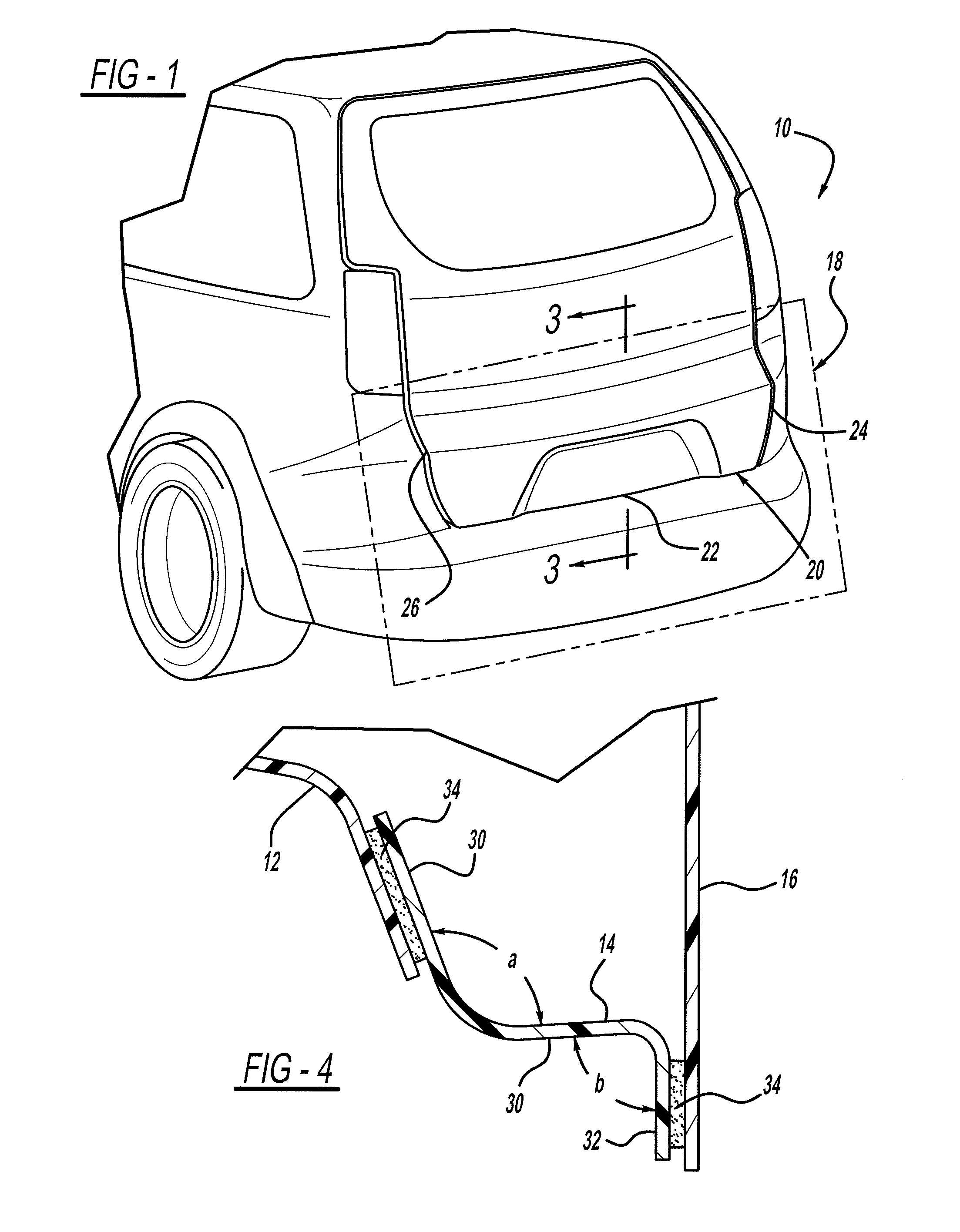

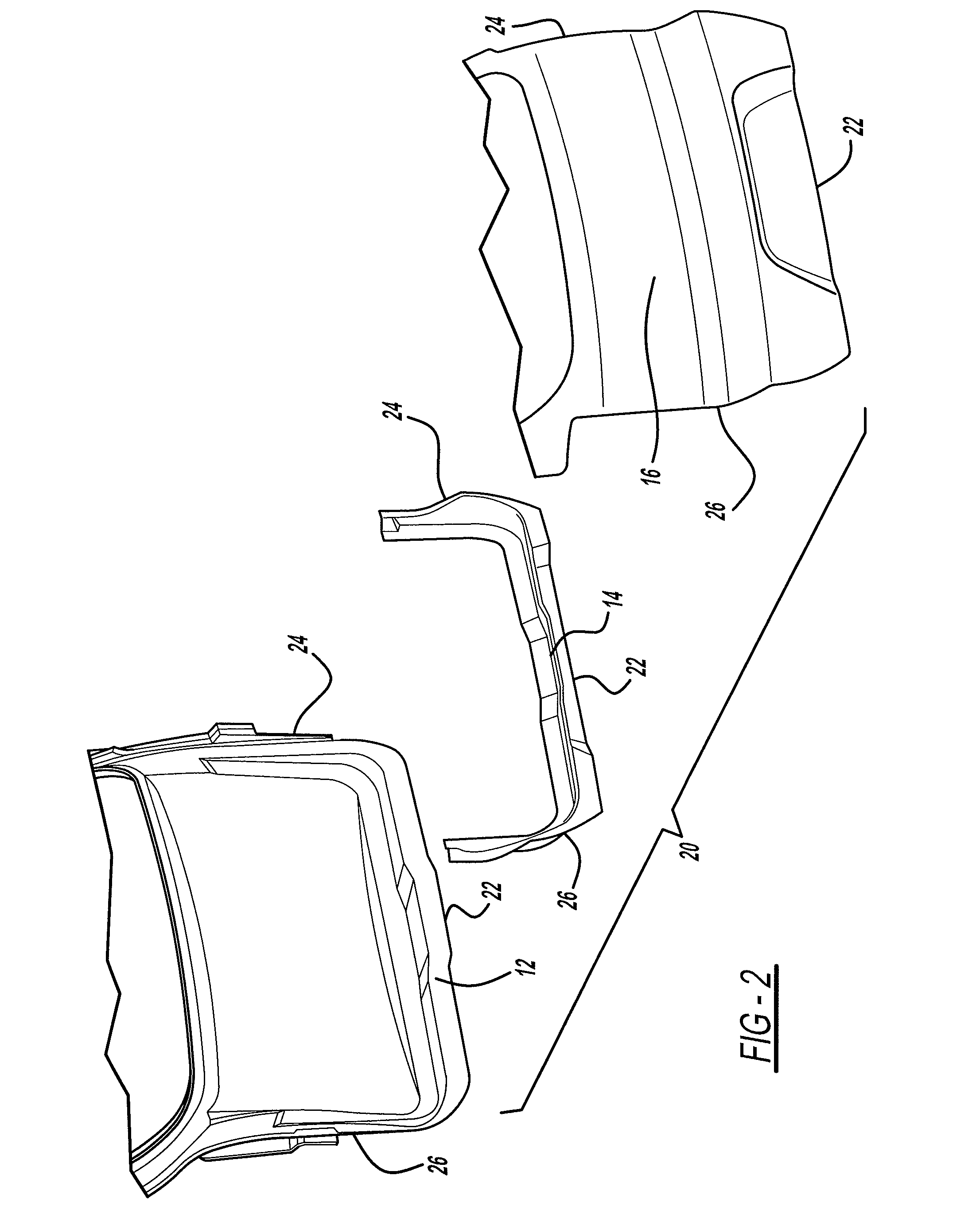

[0016]An embodiment of a composite lift gate, according to the present invention, is shown in the Figures, generally at 10. In this embodiment, the lift gate 10 includes an inner polymeric structural support panel 12, a deformable polymeric section 14, and a polymeric show surface outer panel 16.

[0017]The inner panel 12 is structural, and is substantially rigid, and provides support for the other components of the lift gate 10. The deformable section 14 is attached to the inner panel 12, as shown in FIG. 5, and the outer panel 16 is also attached to the inner panel 12 such that the deformable portion 14 is disposed between and connects at least a portion of the inner panel 12 with the outer panel 16.

[0018]The outer panel 16 is made of a flexible and resilient material suitable for defining a show surface of the lift gat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| crash resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com