Method for controlling a drive train

a technology of drivetrain and control mechanism, which is applied in the direction of hybrid vehicles, electric propulsion mounting, transportation and packaging, etc., can solve the problems of affecting the shifting process, affecting and taking a comparatively long time. achieve the effect of speeding up and increasing the comfort of the gear shi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

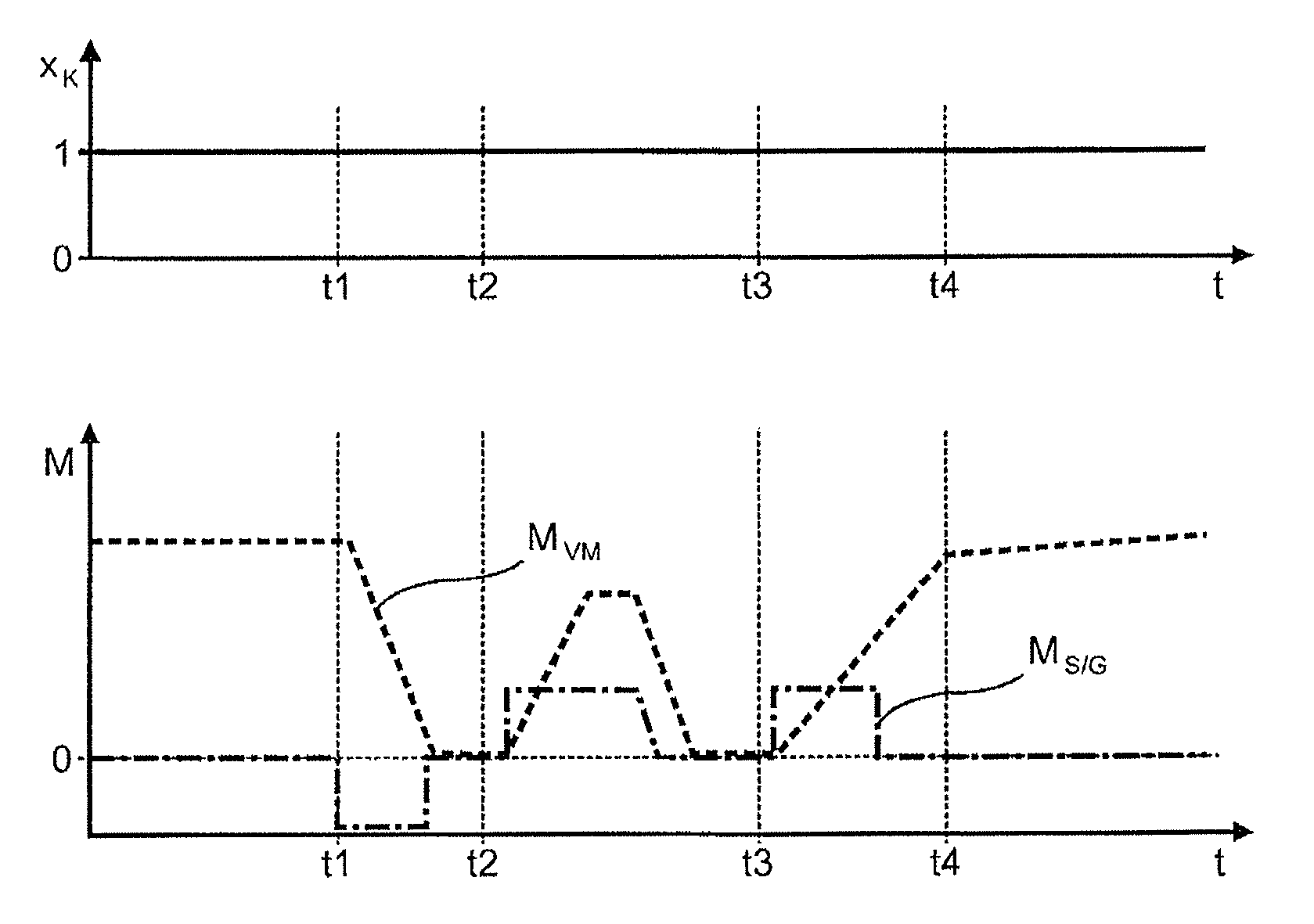

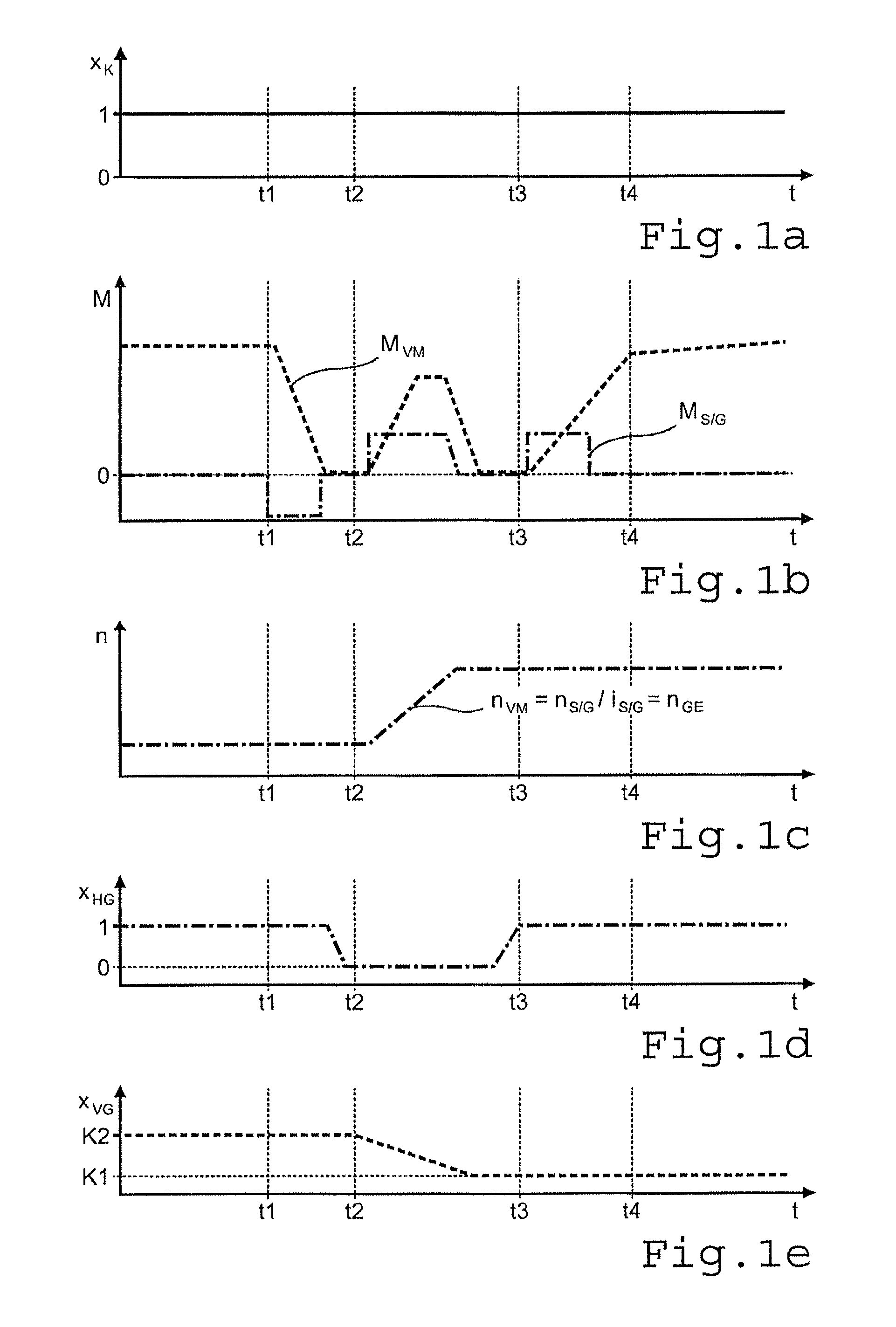

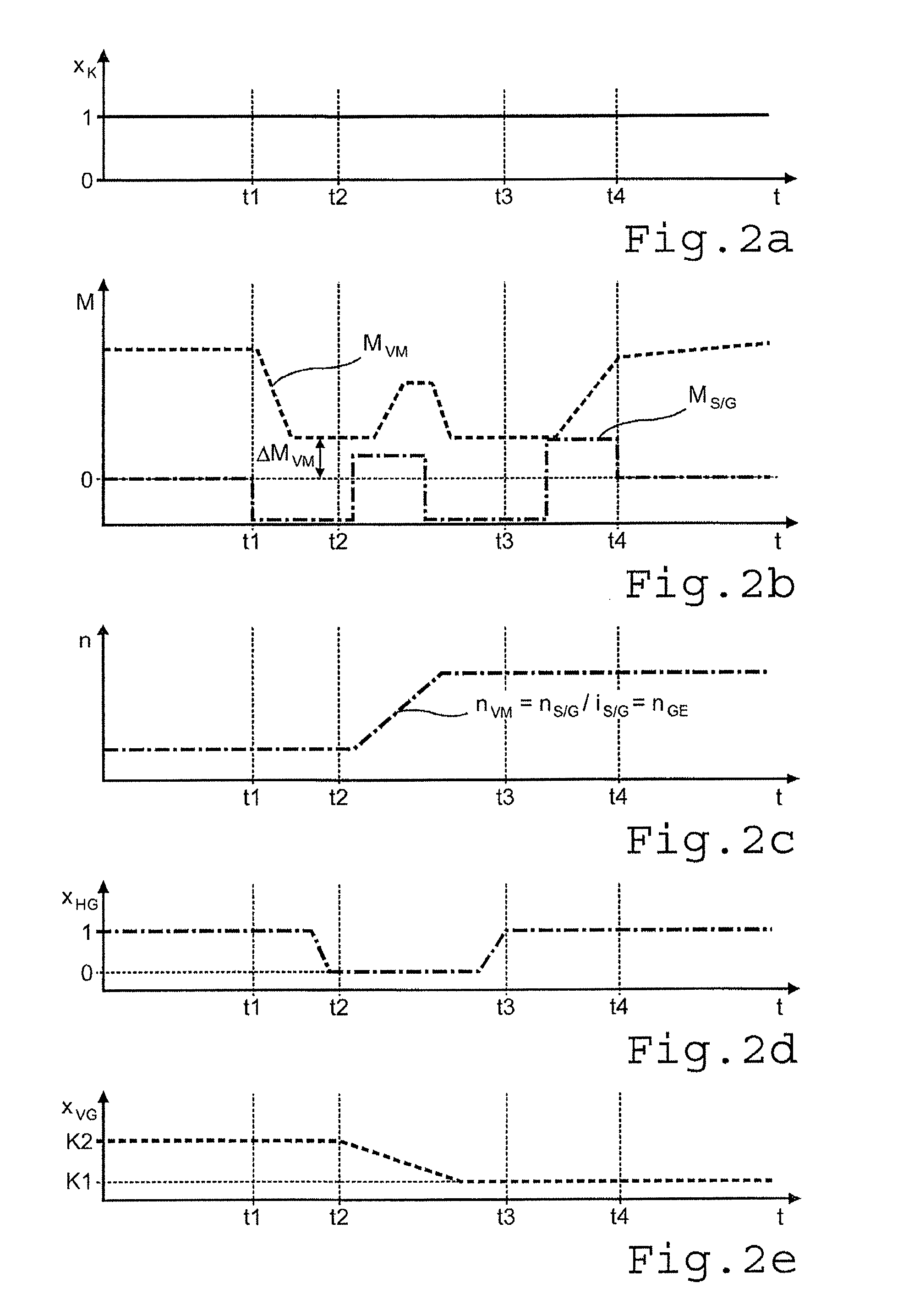

[0076]Below, the above shifting processes of a group transmission comprising a multi-stage main transmission HG and a two-stage splitter group VG connected upstream therefrom, and whose input shaft GE can be connected by an automated friction clutch K to the driveshaft of an internal combustion engine VM which is in driving connection with an electric machine S / G, are explained with reference to the diagrams of FIG. 1 to FIG. 4. The structure of a group transmission of this type can be seen for example in DE 10 2007 010 829 A1 (see FIG. 1a and FIG. 1b therein).

[0077]The present diagrams of FIG. 1 to FIG. 4 each show in part a) the time variation of the degree of closure xK(t) of the friction clutch K, in part b) the torque variation MVM(t) of the internal combustion engine and the torque variation MS / G(t) of the electric machine, in part c) the speed variation nVM(t) of the internal combustion engine and if needs be also the speed variation nGE(t) of the transmission input shaft, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com