Waste water immersion probe

a technology of waste water and probe, which is applied in the direction of vehicle maintenance, material testing goods, applications, etc., can solve the problems of shaft sealing only having a limited sealing effect or reliably sealing, affecting the accuracy etc., to achieve low axial friction force and avoid waste water immersion. , the effect of reducing the risk of waste water immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

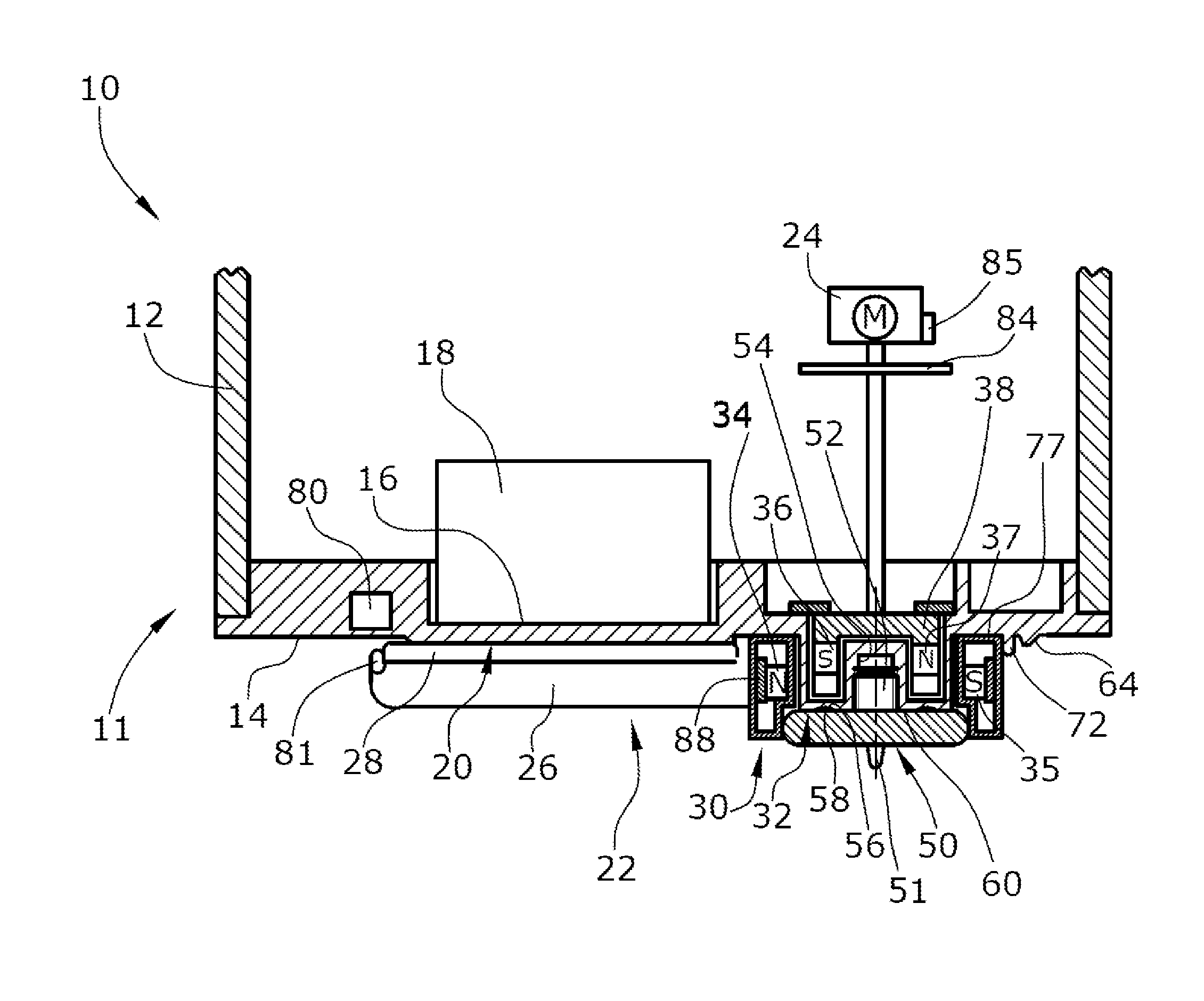

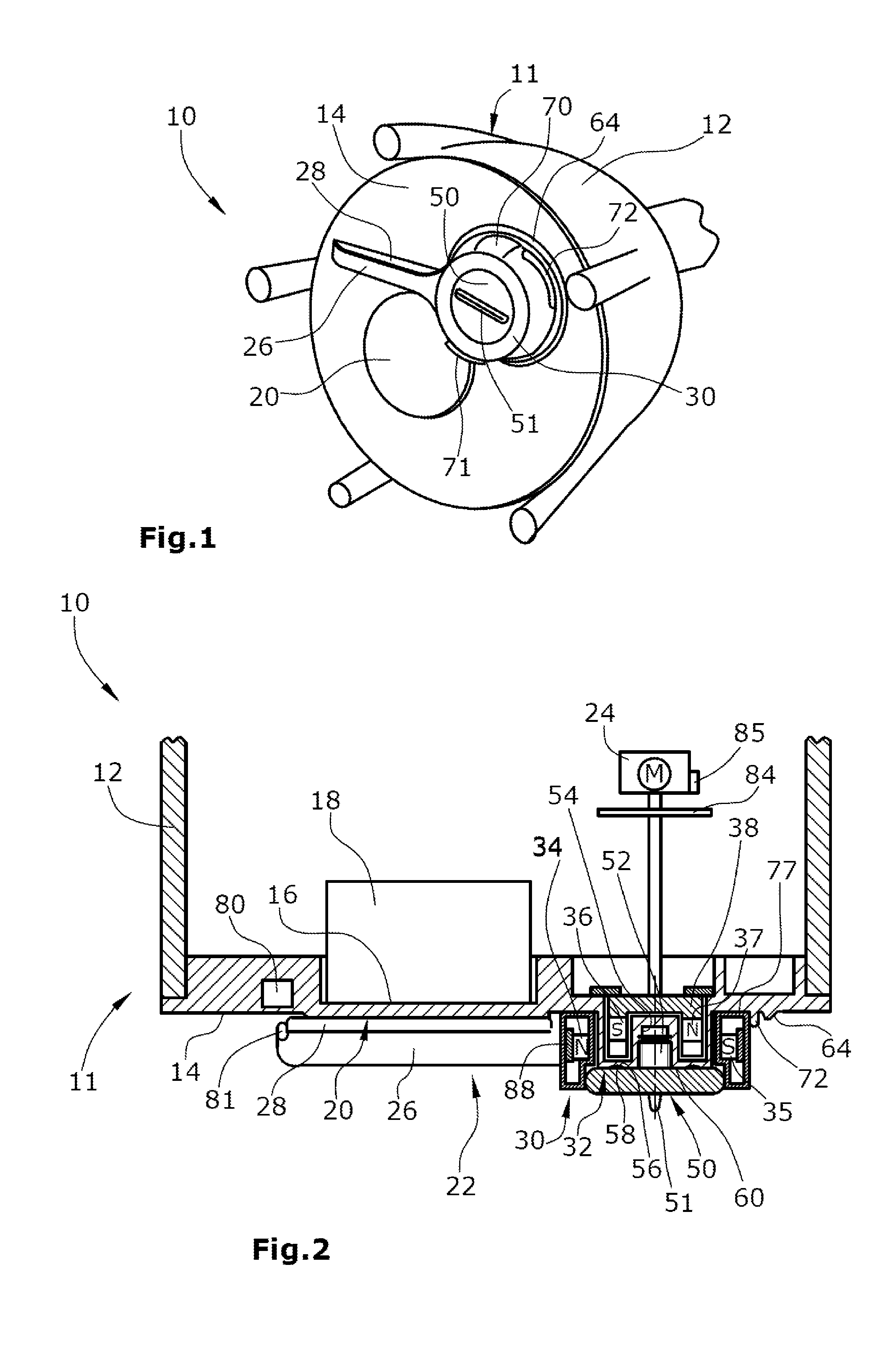

[0021]FIGS. 1 and 2 illustrate a waste water immersion probe 10 which, in the present case, is designed as an ultrasonic sludge blanket probe. The immersion probe 10 has a bipartite housing 11 formed by a pot-like housing body 12 and a circular disc-shaped housing cover 14 that forms the bottom housing wall of the housing 11. The housing body 12 is made of metal, whereas the housing cover 14 is made of plastic material. The housing body 12 and the housing cover 14 are fluid-tightly connected, e.g. screwed, glued or locked to each other. The waste water immersion probe 10 is intended for operation under permanent immersion in waste water.

[0022]On the inner side of the housing cover 14, a sensor 18 is arranged in a recess 16, which is designed as an ultrasonic sensor. The bottom of the recess 16 forms a sensor window 20 thin enough for the ultrasonic waves emitted and received by the ultrasonic sensor 18 to pass through in both directions substantially unimpeded.

[0023]The ultrasonic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic field | aaaaa | aaaaa |

| wiping movement | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com