System for testing and sorting electronic components

a technology for electronic components and systems, applied in individual semiconductor device testing, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of reducing led sorting speed and throughput, and achieve the effect of increasing the overall throughput and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The preferred embodiment of the present invention will be described hereinafter with reference to the accompanying drawings.

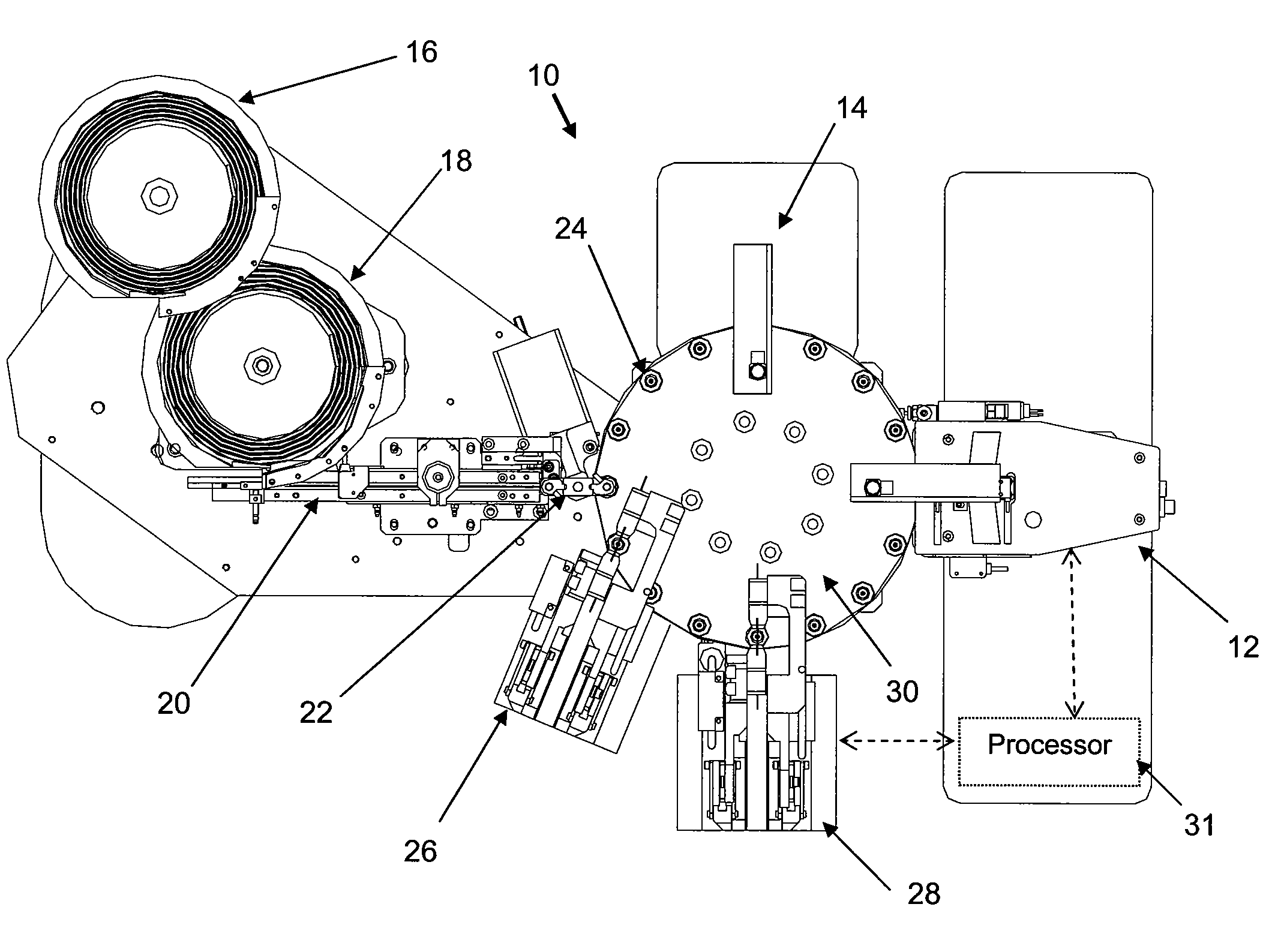

[0019]FIG. 1 is a schematic top view of a first tray, such as a high speed bin tray 12 according to the preferred embodiment of the invention, superimposed over a second tray, such as a normal bin tray 14. The high speed bin tray 12 and the normal bin tray 14 have receptacles in the form of bins for receiving tested electronic components, such as LEDs. This figure illustrates the advantage of arranging the bins that are more frequently used into the high speed bin tray 12. As the high speed bin tray 12 has fewer receptacles and is thus smaller than the normal bin tray 14, the motion distance and time taken for an output tube to move from bin a to bin c in the high speed bin tray 12 is shorter than from bin a to bin b. Thus, if a more frequently used bin at position b were to be consolidated into the high speed bin tray 12 at position c, a higher sorting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com