Sorting apparatus for down feather

A sorting device and down technology, applied in sorting, loose filling materials, household appliances, etc., can solve the problems of increasing sorting errors, low efficiency, and the impact of sorting speed, so as to reduce material waste and labor Strength and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

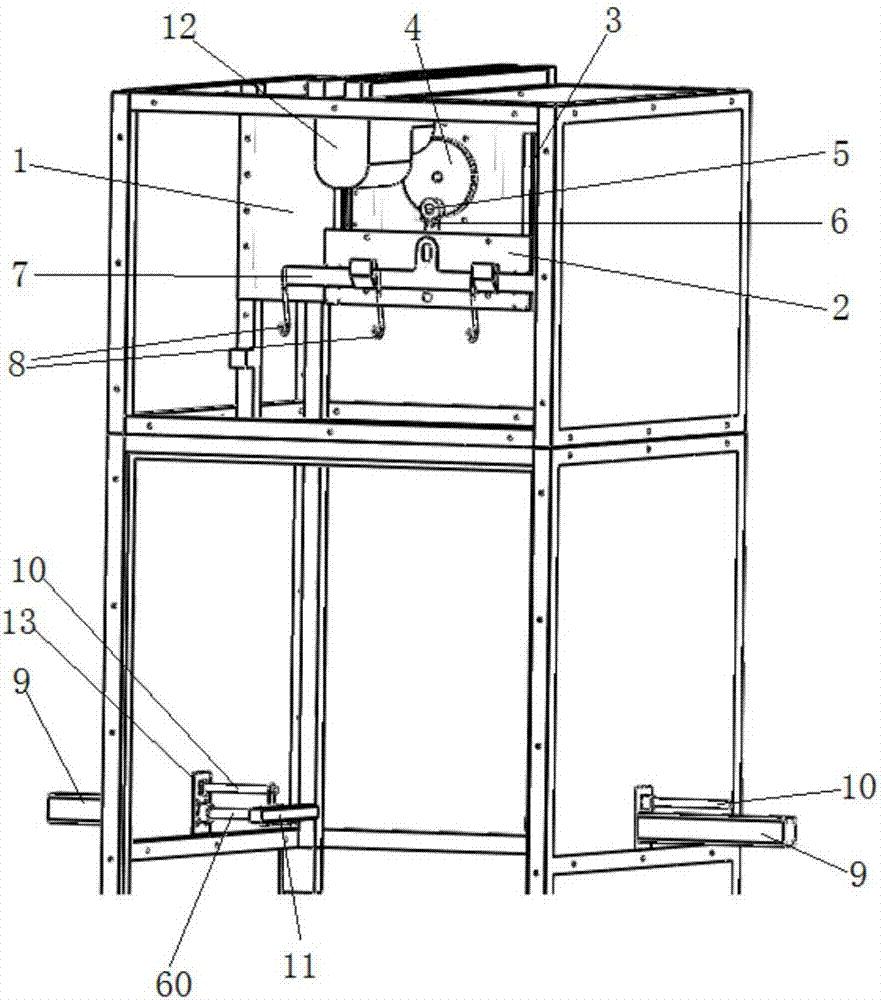

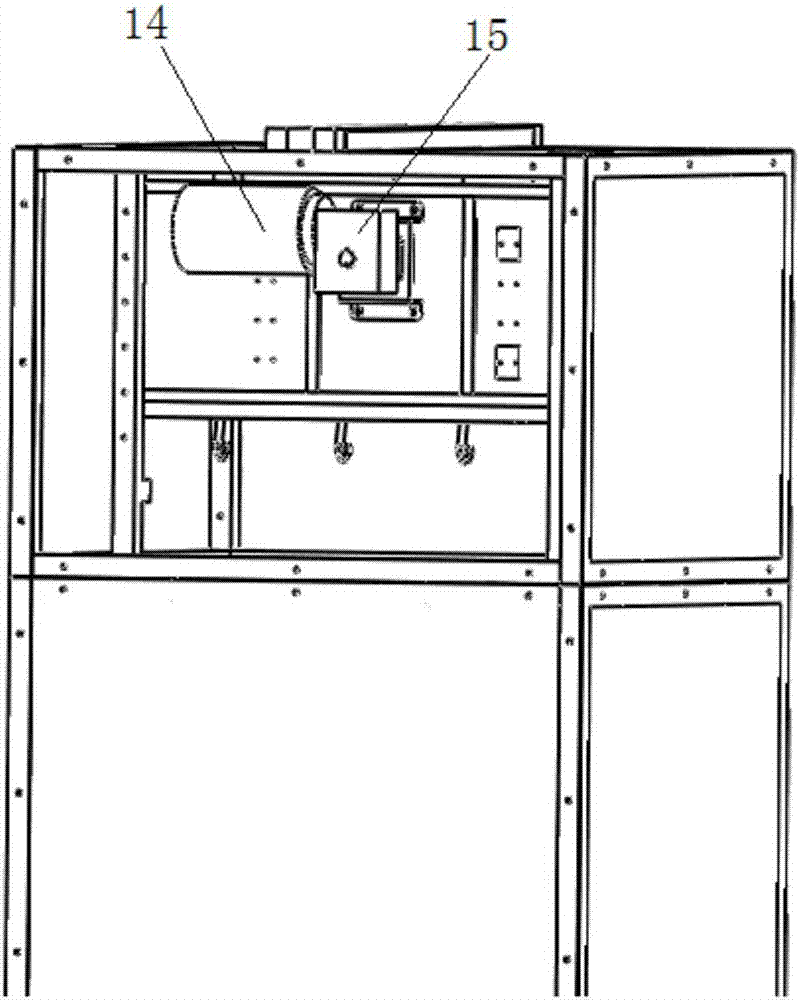

Image

Examples

Embodiment approach

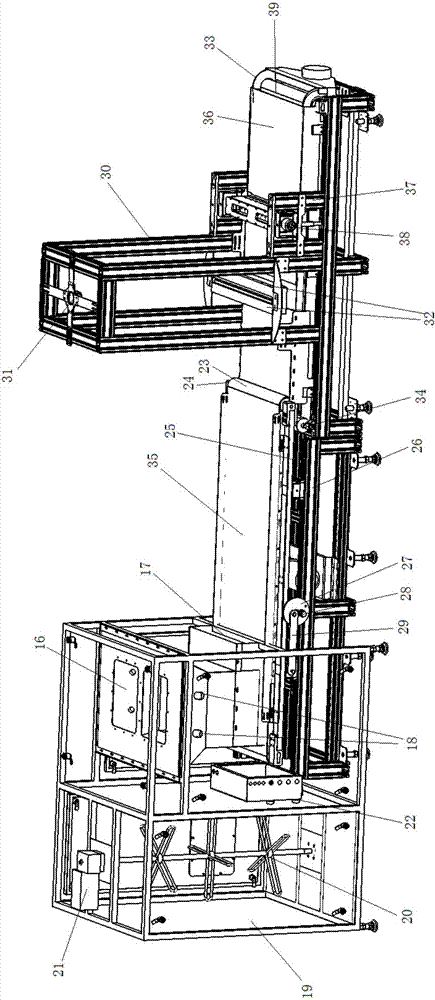

[0064] An embodiment of the velvet suction component includes a velvet suction pipeline, and the control device controls the on-off of the gas path of the velvet suction pipeline. Another kind of embodiment: comprise sorting head, described sorting head is provided with suction suede mouth 49, suede outlet 48, and described sorting head is connected with suction control part, and suction control part controls suede suction port 49 whether suction suede , the down outlet 48 discharges the eider down sucked by the down suction port 49.

[0065] The down-absorbing port 49 faces downwards (including front facing and angledly facing) the down conveyor belt 39, and any position on the down conveyor belt 39 moves below the velvet picking device when there is a down-absorbing port 49 and the down conveyor belt. Corresponding; when there is eiderdown that needs to be sorted on a certain position of the eider down conveyor belt 39, the down suction port 49 corresponding to a certain pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com